Mastering Center of Gravity Analysis in Supply Chain Network Design – Best Practices

In supply chain network design, Center of Gravity (CoG) or Greenfield analysis is a crucial method for determining the optimal number and location of key facilities such as distribution centers, warehouses, or manufacturing plants within a supply chain network.

By pinpointing the most strategic locations, businesses can significantly reduce transportation costs, cut lead times, and improve service levels, ensuring that the logistics footprint is tightly aligned with demand patterns and supply chain constraints. This makes CoG analysis a cornerstone of any successful network optimization strategy.

The CoG Analysis Process

A comprehensive CoG analysis follows a two-step process:

- Identifying Hotspot Locations

The first step involves identifying potential hotspot locations based on various factors, such as demand distribution and the current location of facilities. These hotspots act as candidate locations for future distribution centers or warehouses. - Evaluating Trade-offs

The second step involves evaluating these candidate locations within the context of the entire supply chain, weighing trade-offs between transportation costs, service levels, and other strategic priorities. This enables companies to determine the CoG that will best fit their network.

The first step should never be used in isolation to determine final project results. Instead, it should serve as an initial ideation phase to identify potential facility locations within a broader, more comprehensive network design study in step two.

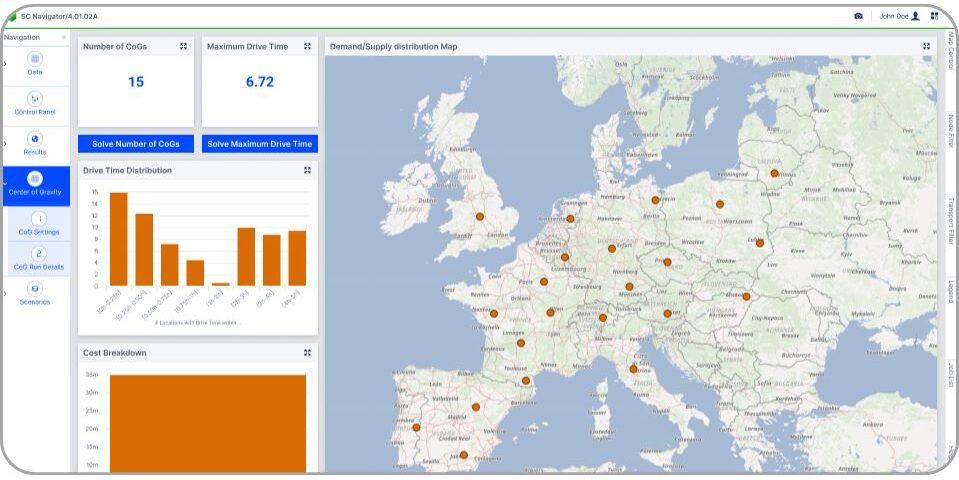

Advancing CoG Analysis with AIMMS SC Navigator

While the traditional CoG process is invaluable, it can be significantly enhanced with advanced features like those available in SC Navigator.

The Constrained CoG feature allows users to incorporate specific business constraints into the analysis, ensuring that proposed locations meet particular business requirements.

Additionally, SC Navigator’s CoG Trade-Off feature allows for the comparison of multiple scenarios by adjusting the weightings of cost and service levels, providing businesses with deeper insights to make more informed location decisions. These powerful tools make CoG analysis more adaptable and precise, allowing for a more tailored approach to network design.

Learn more about these advanced CoG features in SC Navigator.

Best Practices for CoG Analysis

To ensure a successful CoG analysis, we’ve outlined the essential steps and best practices that you should follow:

- Run Unconstrained CoG Scenarios Based on Demand: Start by running a CoG analysis without any restrictions. This gives an initial view of natural hotspots based on demand distribution.

- Fix Existing Strategic Locations: Ensure that critical facilities such as current distribution centers and strategic hubs are incorporated and ‘Fixed’ into the analysis, as these must remain in the network.

- Run and Test Different CoG Algorithms: Run scenarios around the number of CoG locations and drive-time requirements to test different configurations, ensuring that both service levels and delivery efficiency are met.

- Conduct a Constrained CoG Analysis: Incorporate true business rules and constraints into the CoG analysis, ensuring that it aligns with real-world constraints like capacity, geography, and service-level agreements.

- Compare CoG Locations with Existing Facilities: Cross-reference your CoG-generated hotspots with existing locations, which are superimposed automatically in the SC Navigator app, to evaluate their relevance and refine the candidate list based on business knowledge and analysis results.

- Incorporate Locations into the Network Design Model: Seamlessly integrate the identified CoG locations into your broader supply chain design, ensuring that insights from the CoG analysis are fully embedded into the network strategy.

- Re-run Full Network Optimization: With the selected candidate CoG locations now part of your design, perform a full network optimization to evaluate the impact of these locations on overall supply chain performance.

- Run What-If Scenarios: Test the impact of opening or closing certain CoG locations. This allows you to explore different configurations and assess the role of each facility within the network, ensuring you make the most informed decision about which locations should be included.

In Summary

CoG analysis is an iterative and dynamic process that requires continual refinement as supply chain conditions change. To be effective, the right tool must not only support this iterative process but also empower decision-makers with advanced algorithms, intuitive visualizations, and flexible scenario planning.

AIMMS SC Navigator is an industry-leading solution that delivers all of this and more, making CoG analysis smarter, faster, and more adaptable, ultimately helping businesses optimize their supply chain networks with confidence.

Ready to find out how to optimize your supply chain network for your company? Talk to our experts today!