Diversifying Supply Chain Locations During Global Tariff Wars

Tariff wars and geopolitical shifts have redefined global supply chains, making diversification a strategic necessity. Today we see important trends shaping up like the acceleration of regionalization, the increasing role of technology in supply chain planning, and the necessity of scenario modeling, network design, and location risk analysis to navigate disruptions effectively.

What are recent research reports showing?

AIMMS & Iter’s “Trump’s Trade Tightrope: A Global Supply Chain Outlook” report highlights similar critical trends shaping supply chain resilience.

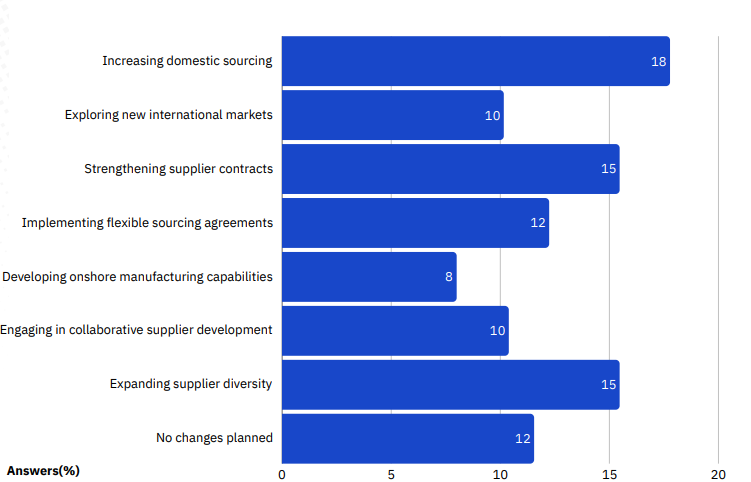

For example, in the new geopolitical context, U.S companies are focused on boosting domestic sourcing, explore new international markets and supplier diversity.

Figure: How prepared is your organisation to adapt to regulatory changes and trade policy uncertainties?

Source: Iter and AIMMS

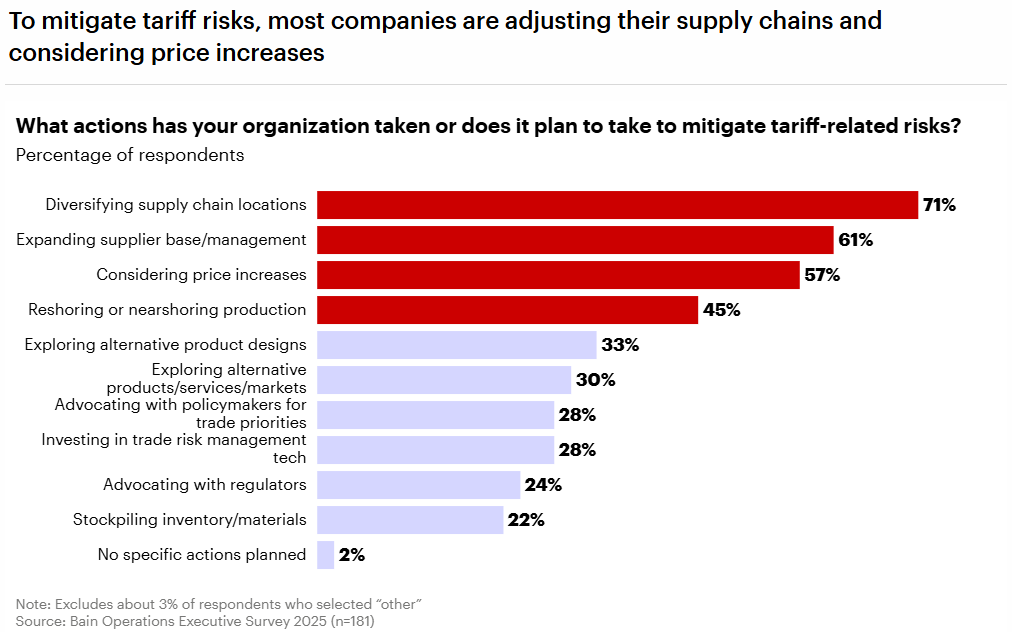

Another cool research from Bain’s “Beyond Tariffs: The Supply Chain Reinvention Imperative” stresses the urgency of reinventing supply chains beyond tariffs, focusing on risk management, digitalization, and geographic diversification. The research is based on a executives survey and emphasizes how companies must innovate to cope with disruptions. The figure highlights strategies for this transformation, comparing traditional models to modern approaches.

Bain’s analysts outline three key principles for executives redesigning supply chains.

- First, companies should think without constraints, starting with the ideal future state and planning boldly.

- Second, supply chains must be managed as a complex, interconnected system, considering all variables.

- Lastly, companies should upskill talent, upgrade digital tools, and improve management systems to enhance responsiveness and strategic decision-making. These strategies have led companies to improved resilience, cost savings, and growth.

Strategic approaches to supply chain diversification

Decisions related to supply chain de-risking must come from the top of the organization, as they could impact the core manufacturing or distribution processes. Incorporating this in the strategy is key.

- Scenario modeling for resilient decision-making

Scenario modeling enables companies to anticipate the impact of tariff fluctuations and geopolitical changes before they occur. Bain’s report emphasizes the importance of simulating different trade policy outcomes to proactively adjust sourcing and manufacturing strategies.

Actionable Steps:

- Use scenario planning tools to evaluate multiple tariff scenarios.

- Model cost impacts, supplier viability, and logistics disruptions under different regulatory conditions.

- Develop contingency strategies for key suppliers and manufacturing locations.

- Network design studies for optimized distribution

Research data highlights the need for re-evaluating distribution networks to improve cost efficiency and resilience. Companies should reassess their supply chain footprint, identifying optimal locations for manufacturing, warehousing, and distribution.

Actionable steps:

- Conduct a network design study to balance production costs, tariffs, and lead times.

- Optimize logistics routes by assessing transportation costs and regional trade agreements.

- Leverage digital twin technology to simulate supply chain shifts before implementation.

- Location Risk Analysis for supply chain stability

Selecting new locations requires a thorough risk assessment of factors like political stability, infrastructure, and regulatory policies. Bain’s report underscores the increasing importance of labor availability and trade compliance in these decisions.

Actionable steps:

- Evaluate macroeconomic, political, and environmental risks for potential supply chain hubs.

- Monitor real-time geopolitical developments that may impact supplier reliability.

- Diversify supplier base across multiple low-risk regions to reduce dependencies.

Practical steps for Implementation

Supply chain leaders are now heavily focused on:

- Nearshoring & Regional Diversification: Move production closer to key markets (e.g., Mexico for U.S. firms, Eastern Europe for EU firms) to reduce tariff exposure and improve agility.

- Dual-sourcing & supplier redundancy: Avoid over-reliance on a single supplier by developing alternative sourcing strategies.

- Technology-enabled decision-making: Invest in prescriptive analytics for real-time monitoring of trade policies, risk assessment, and supply chain performance optimization.

Conclusion

As tariff wars and trade uncertainties continue, supply chain diversification must be approached strategically. Companies that leverage scenario modeling, network design studies, and location risk analysis will be better positioned to navigate disruptions, optimize costs, and ensure long-term resilience. By embracing data-driven decision-making, businesses can future-proof their supply chains in an increasingly complex global trade environment.

Ready to find out how to optimize your supply chain for your company? Talk to our experts today!