Money Talks: A case for Integrated Supply Chain Optimization

As we discussed in our previous blogpost, Integrated Supply Chain Optimization offers undeniable benefits for your organization. The industry is abuzz with talk about this trend as well. ORTEC’S John Poppelaars referred to this approach as the optimization of the value chain in a recent post, and leading supply chain blogger Lora Cecere shared an urgent pitch for horizontal collaboration and planning over the entire value chain on Forbes earlier this month.

Still, why would you go through all the trouble involved in adopting this approach? Your business is still running. Your sales team is comfortable with their routine process for building demand scenarios, operations aptly match your supply capabilities, and your finance department makes sure that possible mismatches between demand and supply are decided on based on financial parameters. The monthly cycle only needs minor tweaking in the weekly reviews. So there’s plenty of time for the daily job of firefighting – or dealing with all possible disruptions in the supply chain.

Still, why would you go through all the trouble involved in adopting this approach? Your business is still running. Your sales team is comfortable with their routine process for building demand scenarios, operations aptly match your supply capabilities, and your finance department makes sure that possible mismatches between demand and supply are decided on based on financial parameters. The monthly cycle only needs minor tweaking in the weekly reviews. So there’s plenty of time for the daily job of firefighting – or dealing with all possible disruptions in the supply chain.

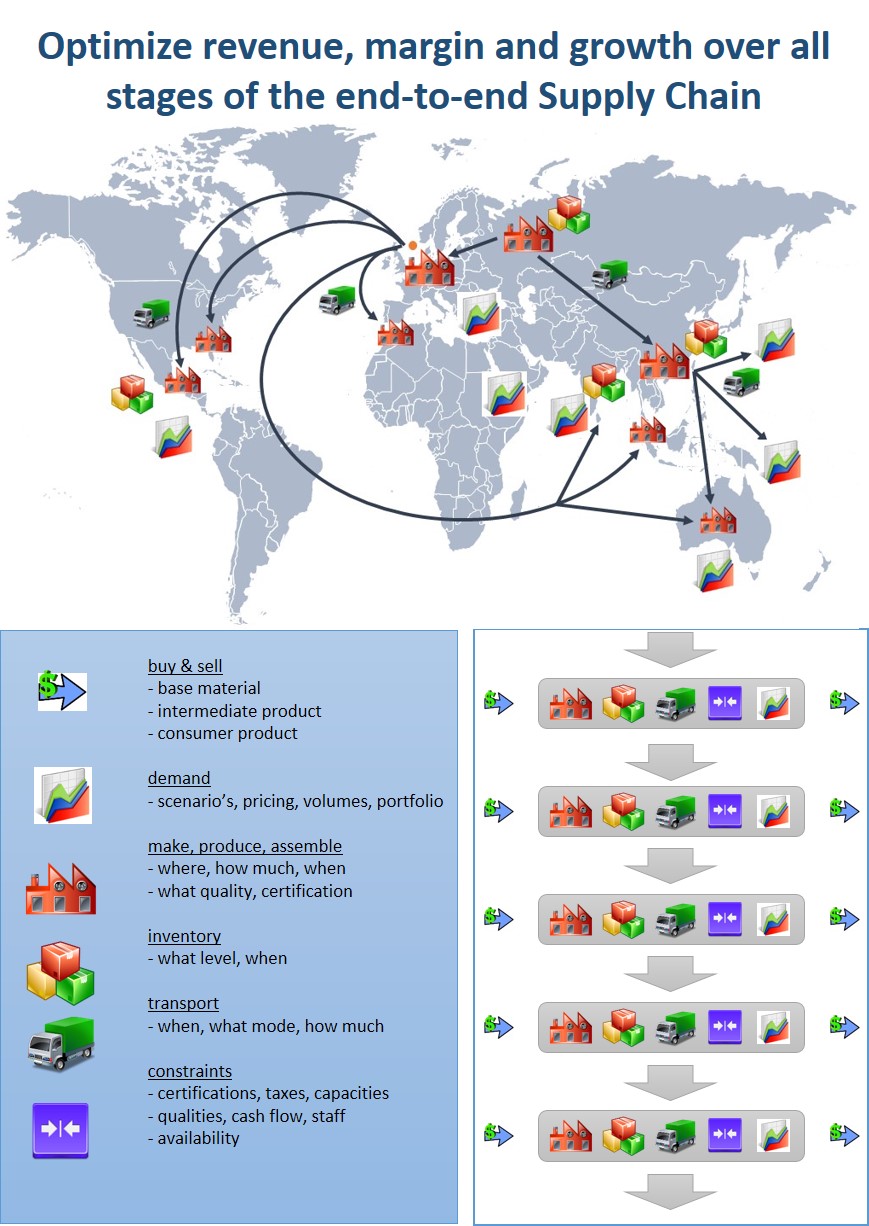

Are you really extracting all the possible value out of your supply chain though? Suppose you could put all possible scenarios for demand, supply, logistics and finance into one box that would provide you the best solutions for three different objectives on short notice:

- Highest business margin

- Highest business revenue

- Highest asset utilization

How much more insight would that give your financial board? How much time do you now spend on finding feasible solutions? What if you used that time to find innovative solutions instead?

Suppose you could make this assessment ‘on the fly,’ based on your latest market and operational data. What would the value of this assessment be? For instance, let’s say you had assumed a purchase price of raw material of 35, but it turns out to be 38. How does this impact your business planning? Would you still stick to the same volumes? Same vendor? Same sales price? Same production location?

What if a critical step in your production line breaks down for 2 days? Would you know what the best possible response would be? Sticking to the plan is not feasible anymore, and without the right tools key decision-makers will probably struggle to come up with the best alternatives.

Let’s look at a real-life case study

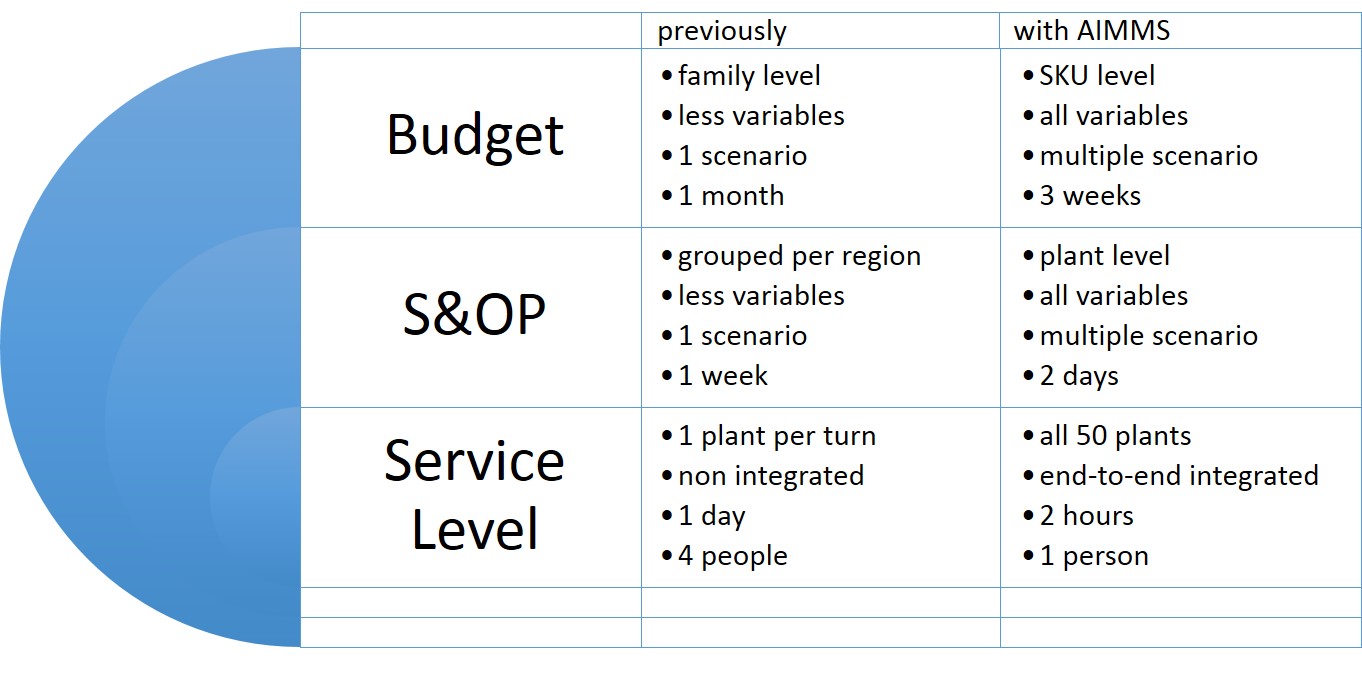

As there´s nothing better than a real world example, let’s look at how JBS, a world leading meat processing company with 27 billion revenue in Brazil, has dealt with this kind of situation. They have over 50 plants in Brazil alone and used to have a well established ‘classic’ IBP process (sketched below). It was comprised by a monthly balancing cycle and a weekly update cycle – both of which were based on a single scenario – and supported through lots of spreadsheets going around the company. The resulting mid-term business plan was processed into a master production schedule, where discrepancies with the IBP would surface. These discrepancies needed to be resolved within a weekly cycle. Assumptions were made on market prices to buy and sell meat products, and monthly schedules determined the sales scenarios and sourcing schedules.

On the supply side, operations needed to find out how to best meet demand and which plants they should allocate the produce to, taking into account specific requirements like halal, kosher, and the legislation of the countries which would eventually receive the end products. As this was quite complex to plan & schedule over 50 plants, It was done per region and based on rules of thumb.

The Supply Chain of your Dreams

Then, JBS decided to redesign their processes to allow for a systematic assessment and optimization of multiple scenarios on a much more detailed level. The system that they developed, enables them to respond rapidly to changing market prices for all of their (intermediate) products on a daily basis. In addition, it allows them to compare these insights with the latest update of their demand scenarios, production capabilities, transport possibilities, and all associated costs. The system provides a means to an end: to use all that data to define the best possible way forward, considering all aspects of the business. Using an iterative approach they revise their business plan on a daily basis, optimizing their business decisions from a holistic perspective.

What does this system bring them? To start with, it results in hard cash, increasing their contribution margin by 3 percent points. That was a 25% increase to their original margin. It also improved their ‘adherence to plan’ by over 90%.

Furthermore, this new approach also brought the company the following intangible benefits:

- Agility in re-planning to changes in the company or its environment

- Clarity in corporate governance

- Instead of a single feasible scenario, there are always multiple scenarios on the table

- Clarity for the planning teams, boosting collaboration in the company

- Transparent planning process which connected all departments

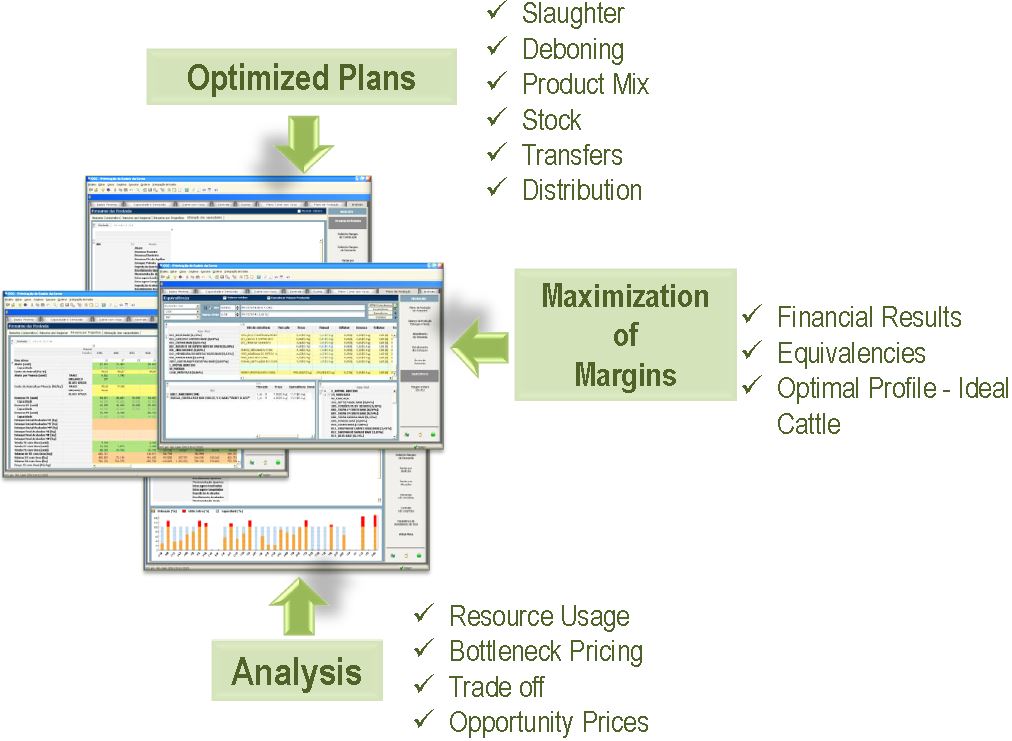

JBS’ optimization model captures the entire supply chain process, from the purchasing of cattle via various stages of production, to distribution. It also determines the optimal product portfolio, sets inventory levels, and plans inter-company transport.

In doing so, it takes into account the available resources and operational costs, which is quite standard for regular APS systems. It also adds prices for the sale and purchase of intermediate products into the business planning picture, and not just for the purpose of reporting. It actually maximizes the margin by continuously trading of cost of purchasing intermediate product, cost of making it yourself, potential revenue of selling now, and potential revenue of selling product one or more production stages down the line. In short, it allows the company’s sales team to identify opportunities from a margin perspective, fully leveraging opportunities that arise from market situations and production capacity.

Technicalities of Moving Beyond ERP

Like many companies, JBS had some parts of their company planning process embedded in their ERP system. They felt this system held them back in further optimizing their business. Plus, they felt an ERP system isn’t the best environment for rapid calculations, and quick and flexible scenario preparation, analysis and evaluation. JBS realized that in order to make the next step in optimizing its business planning process, it had to break new ground in systems architecture. They removed all planning activities from their ERP system, and consolidated them into their separate business planning & optimization environment, provided by AIMMS and implementation partner UniSoma.

Interested in learning more about supply chain optimization? Follow us on Twitter for more updates.

Get a roundup of our best supply chain content every month in your inbox! Sign up for our blog digest here.