5 Reasons Why You Need Advanced Analytics in S&OE

Sales and Operations Execution (S&OE) is a hot topic right now. It’s easy to see why. S&OE is that phase in the planning process where you must react quickly and accurately if something unexpected occurs on any given day. In other words, it’s where firefighting typically happens, and we know that’s been happening a lot lately. We carried out some research on S&OE over the past few months and published the findings in a new report. Read on to get insights from our survey. You’ll also uncover some compelling evidence that makes the case for advanced analytics and optimization in this space.

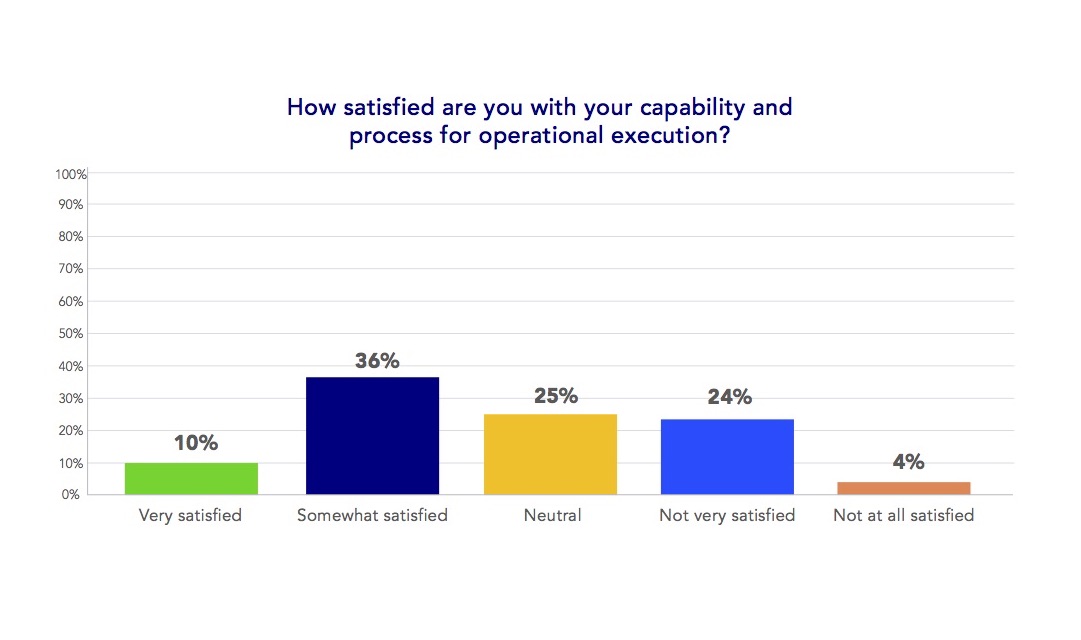

Exhibit 1: Only 10% of respondents are very satisfied with their capability and process for S&OE

Our research was conducted in the first months of 2021, as companies started recovering from the effects of the COVID-19 pandemic. More than 120 supply chain professionals took part. Perhaps unsurprisingly, most of our survey respondents work in industries that experience a lot of variability in short-term execution. Industries represented in the research include manufacturing, food and beverage, and healthcare.

Out of the respondents, only 10% said they were “very satisfied” with their S&OE capability and process. On the whole, more than half of professionals appear to be neutral or dissatisfied. 36% are “somewhat satisfied.”

This shows there’s plenty of room for improvement. Perhaps one of the reasons behind the low levels of satisfaction is the prevalence of volatility.

This shows there’s plenty of room for improvement. Perhaps one of the reasons behind the low levels of satisfaction is the prevalence of volatility.

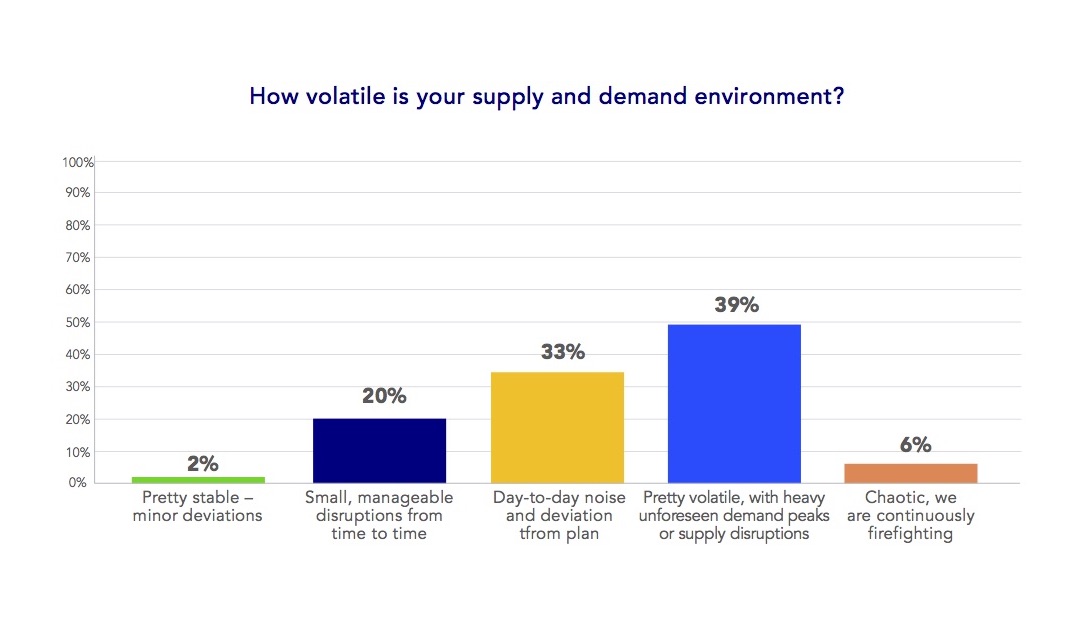

Exhibit 2: 45% experience considerable volatility in supply and demand

Almost 40% of respondents state their supply and demand environment is pretty volatile, with heavy unforeseen demand peaks or supply disruptions. 6% say it’s very chaotic and have to continuously firefight. Only 2% see minor deviations to the plan.

Besides the volatile environment, there is a lot of complexity that goes into a typical S&OE process.

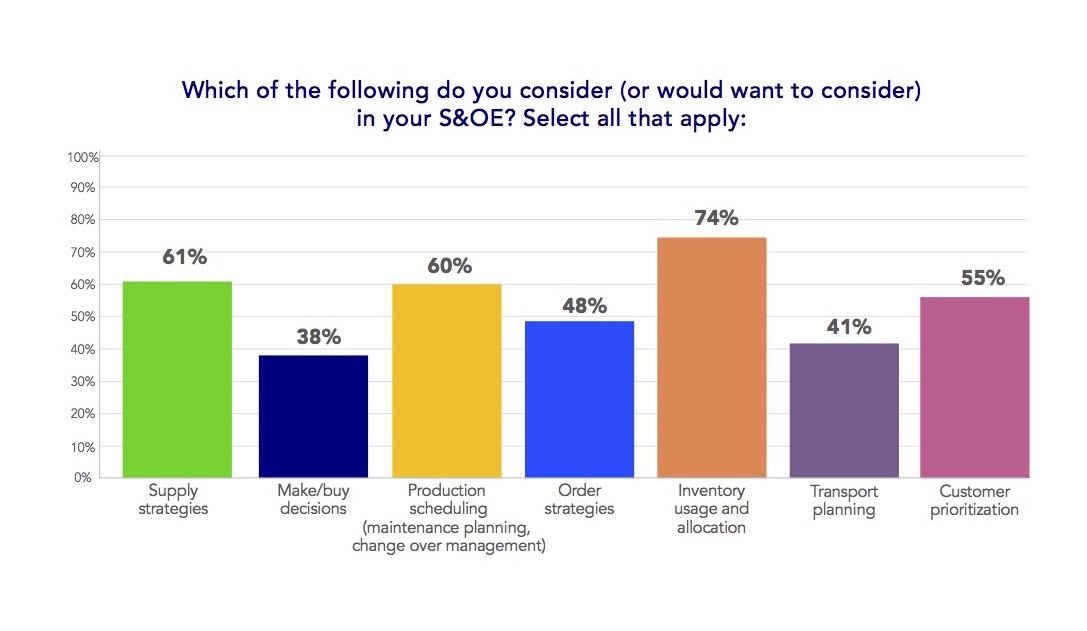

Exhibit 3: There are many considerations to juggle in S&OE

74% of respondents want to (or would like to) consider inventory usage and allocation, 60% want to or are currently considering production scheduling, and 61% are considering or want to consider supply strategies. Customer prioritization is also typically included in the process. With so many things to keep the radar, it can be difficult to focus on improvements.

How are teams managing all of these different variables? What are the technologies in use?

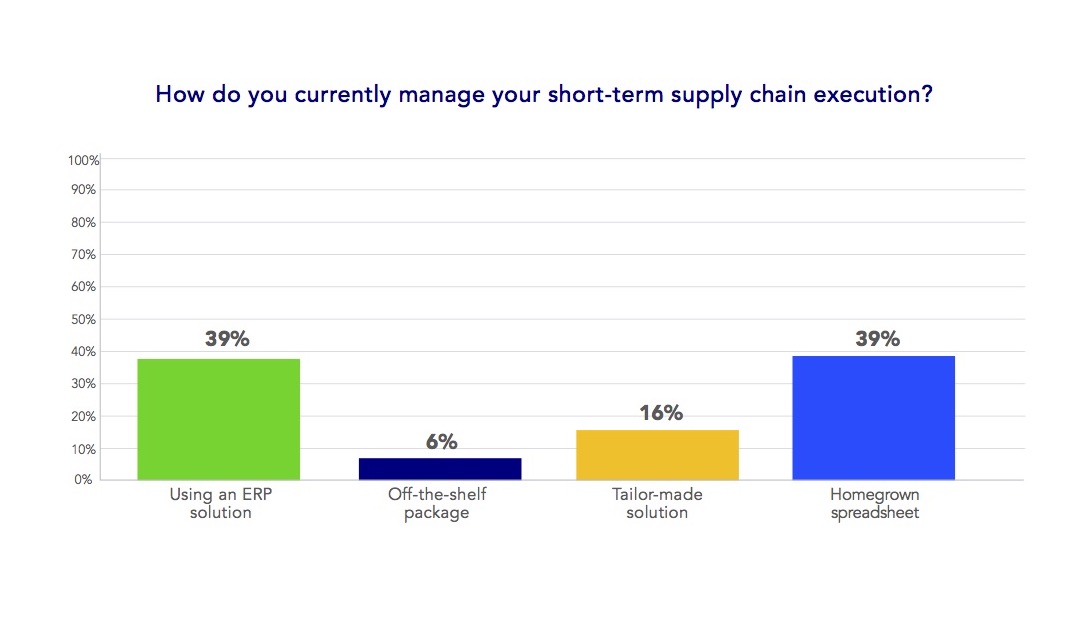

Exhibit 4: Almost 40% are using spreadsheets for S&OE

Digging into the tools used, we found that 39% of respondents use a homegrown spreadsheet to manage S&OE. This is not surprising given that the process is very specific to each company. However, handling S&OE with spreadsheets typically puts a great deal of stress on your planning team and consumes time that could be spent innovating and pushing your supply chain forward.

39% said they use their ERP. Only 16% are using a tailor-made solution and 6% are using an off-the-shelf solution. Respondents said there are several things that hold them back in S&OE decision-making, perhaps due to shortcomings in the technologies used. There appears to be a great opportunity to introduce powerful S&OE optimization at the latest point in the plan, just before it hits your execution systems.

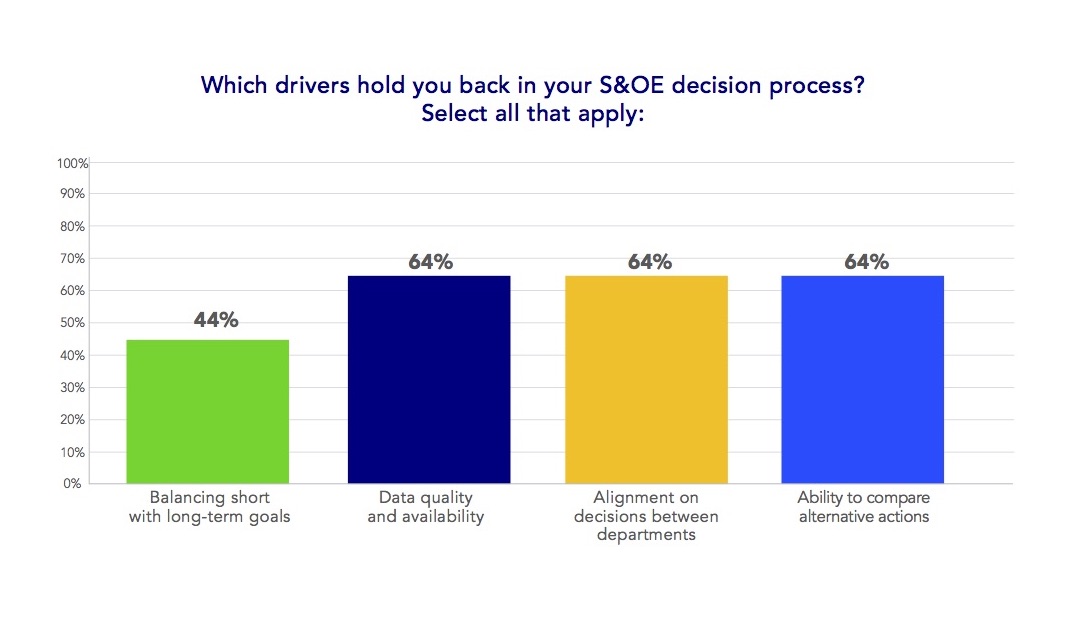

Exhibit 5: 64% struggle to compare alternative scenarios

When asked which drivers hold them back in their S&OE decision process, a clear majority said that data quality and availability, aligning decisions between departments, and the ability to compare alternative actions are currently holding them back. 44% also stated that balancing short-term with long-term goals was a challenge.

The verdict: Complex S&OE decisions require advanced tools

There seems to be a thirst for more data quality in this area, much-needed alignment across departments, and a need for advanced analytics to assess alternative courses of action when disruptions strike. Doing this with an ERP system or using spreadsheets is like putting the wrong tires on your race car. Advanced tooling that comes with scenario analysis capabilities can help your team be the best they can be and facilitate innovation. Deploying optimization in your S&OE process takes your collective planning expertise to a new level. If you’re wondering what it takes to develop such a capability read our blog post with FAQs. We hope these insights help you benchmark your process against peers and improve your S&OE capability.