ArcelorMittal Tubarão Uses AIMMS to Support Sales & Operations Planning Decisions

About ArcelorMittal Tubarão

ArcelorMittal Tubarão (AMT) is part of the ArcelorMittal Group, the world’s leading steel and mining company. Guided by a philosophy to produce safe, sustainable steel, ArcelorMittal is the leading supplier of quality steel products in all major markets including automotive, construction, household appliances and packaging.

Problem

When they first approached UniSoma, an AIMMS implementation partner, AMT planned to expand its yearly production capabilities from 5 million to 7.5 million tons of slabs and rolled coils through the construction of new production units and a new continuous casting machine. The investment of nearly $1 billion would allow AMT to solidify its position in the global slab market. At the time, AMT had adopted SAP – APO® as its tactical and strategic planning tool but the company soon realized that several key business requirements could not be represented within SNP® (“Supply Network Planning”), one of the APO® modules. The AMT team wanted to determine:

- How to sell the expanded capabilities at AMT, in an optimized way – in other words, which was the best production mix

- Which clients (and at what level of service)should be selected to maximize profitability, given the capacity increase in several production areas

Solution

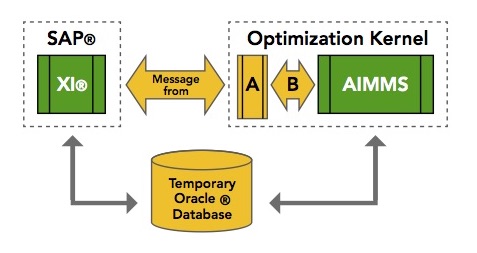

UniSoma built an optimization component as an alternative to the native SNP® engine. An AIMMS-based a model was developed to optimize the Tactical and Strategic Supply Chain Plan at AMT. This module supports optimized and integrated calculations for production, distribution, strategic storage and sales, considering the profitability per client as well as the logistic and production capabilities at AMT and its subsidiary Vega do Sul.

The S&OP (Sales and Operations Planning) tool helps the commercial area establish an optimal client list to maximize contribution margin. The system considers constraints like production capabilities and the client’s product mix – the model guarantees, for each selected client, that the product mix will be completed in a profitable way.

The production planning department at AMT was also provided with a tool that supports the generation of a business plan, according to monthly time buckets, up to a 5 year horizon.

“The AIMMS-based Optimizer developed by UniSoma is the ‘heart’ of the System and the most important component of the project. It optimizes demand based on customer profitability – a request which we did not find in any ‘package’ – indicating the most lucrative flat steel customers for AMT and Vega do Sul.” – Marcia Schwarz de Assis – Project Manager at AMT

Results

- Increase in profitability

- Better planning and purchasing decisions

- Improved ability to meet demand at the desired service level

Solution implemented by AIMMS partner: