What Technology are Teams Using to Support Their Demand Forecasting Process?

Part II in our series on assessing your Demand Forecasting process

In Part I of this series, we looked at supply chain professionals’ perception of forecast accuracy and how they see their forecast evolving in the future. With supply chain complexity on the rise, can new technologies help to improve forecast accuracy and achieve benefits like an optimized inventory and better customer service? Let’s take a look at the demand forecasting technology in use today and what supply chain teams are currently investigating for the future.

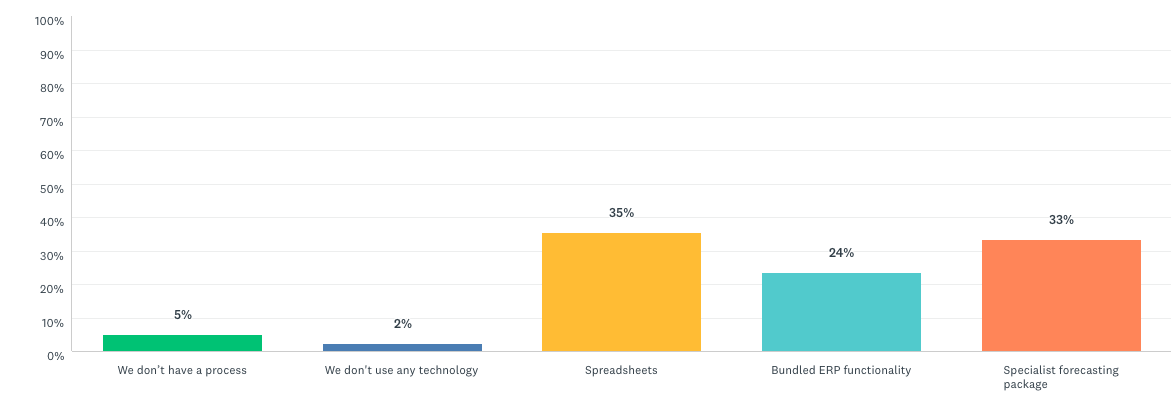

The use of technology for demand forecasting is widespread

Our findings show that the use of supporting technology for demand forecasting is widespread. 34% of respondents use a specialist forecasting package and 35% use spreadsheets. 23% of professionals use Bundled ERP functionality to drive their process. Only 2% stated they don’t use any technology and 5% reported not having a process in place.

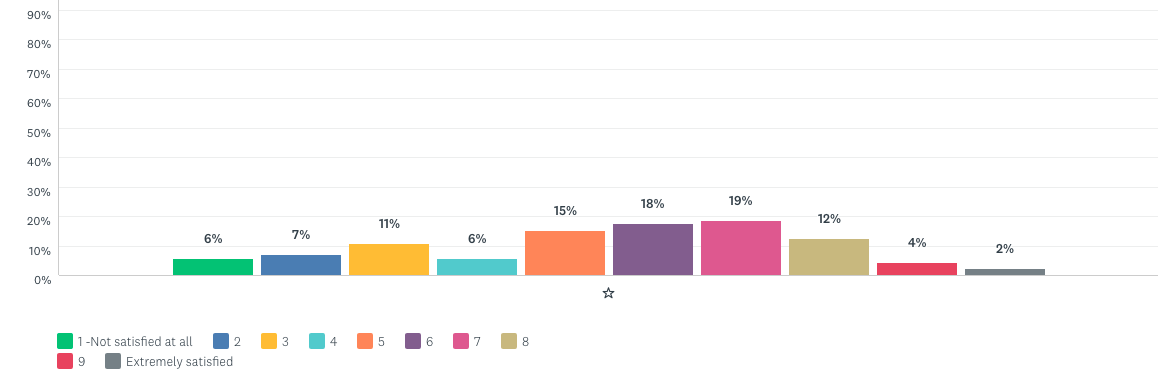

But how satisfied are supply chain pros with the demand forecasting technology at their disposal?

When asked to rate their satisfaction with currently used technologies, only 2% stated that they were extremely satisfied. Most respondents rated their level of satisfaction with the above-mentioned technologies between 5 and 8 (neutral to somewhat satisfied).

Only 2% of supply chain professionals are ‘extremely satisfied’ with their demand forecasting technology. – Tweet this

Drilling down per technology type, 47% of respondents who use spreadsheets reported being dissatisfied (rating between 1 and 4). Only 25.7% of them stated that they were satisfied. Those using specialist forecasting packages are largely satisfied, at 62%. This is stark contrast with those working with bundled ERP functionality. Only 32% of them reported being satisfied with this toolset.

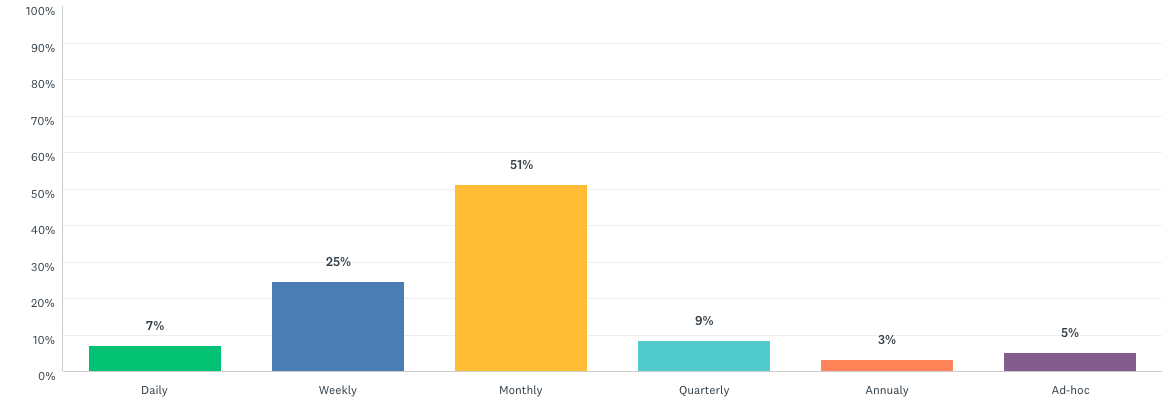

How often do teams review and adjust their demand forecast?

Half of respondents stated that they review and adjust their forecast on a monthly basis. 25% do this on a weekly basis and only 7% do it daily. The type of technology used may influence their team’s ability to do this more frequently.

47% of people using spreadsheets reported reviewing their forecast on a monthly basis; 23% do this weekly and 20% once per quarter. Those who use a specialist forecasting package review their data a bit more often. 51% do it on a monthly basis, 30% weekly and 14.5% daily. The majority of those using bundled ERP perform monthly reviews, at 57%, and 25.5% review their forecast on a weekly basis.

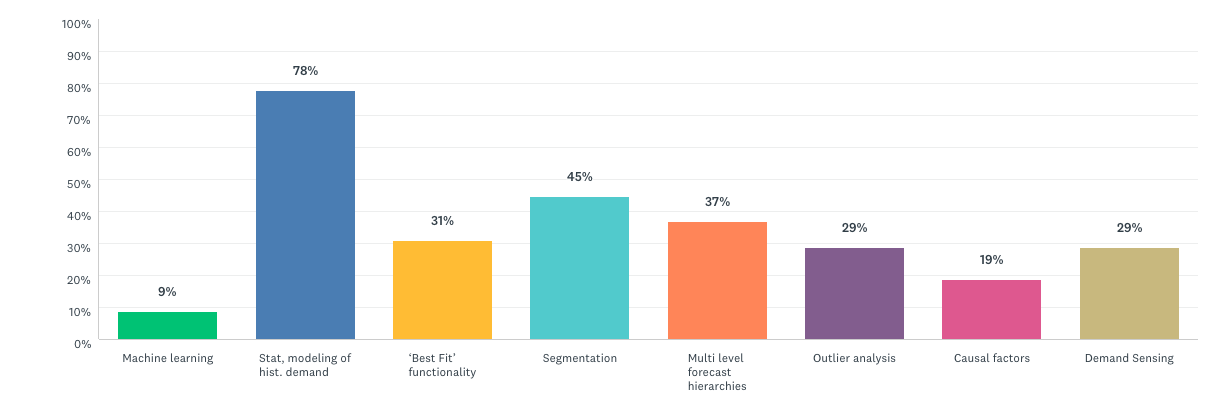

Which techniques are professionals using or currently investigating?

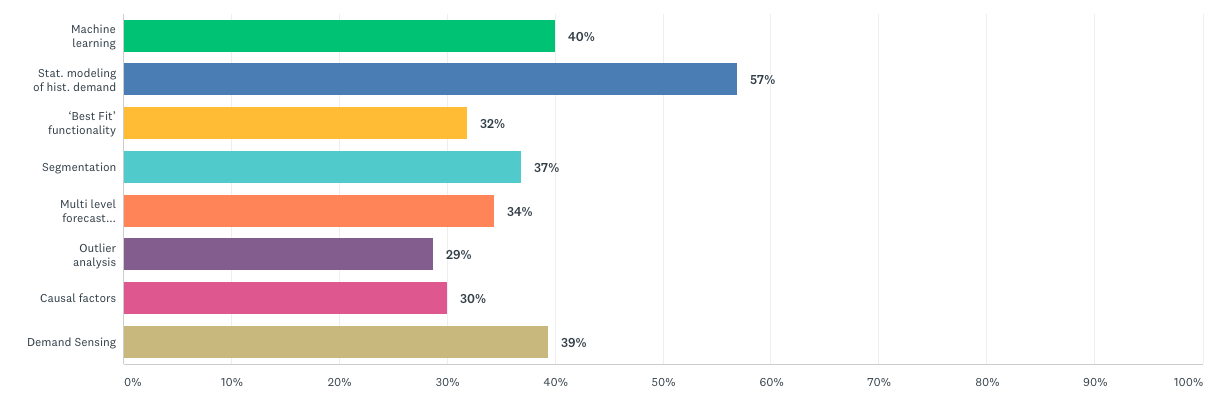

Our research shows that professionals use a wide range of techniques to drive their process. 78% reported using statistical modeling of historical demand, 45% leverage segmentation and 37% use multi-level forecast hierarchies. While only 9% are currently using machine learning, 40% are actively investigating this technique.

40% of supply chain professionals are actively investigating machine learning to drive their demand forecasting process. – Tweet this

Besides machine learning, professionals are exploring other techniques, including statistical modeling of historical demand, multi-level forecast hierarchies, demand sensing, ‘best fit’ functionality and several more.

Besides machine learning, professionals are exploring other techniques, including statistical modeling of historical demand, multi-level forecast hierarchies, demand sensing, ‘best fit’ functionality and several more.

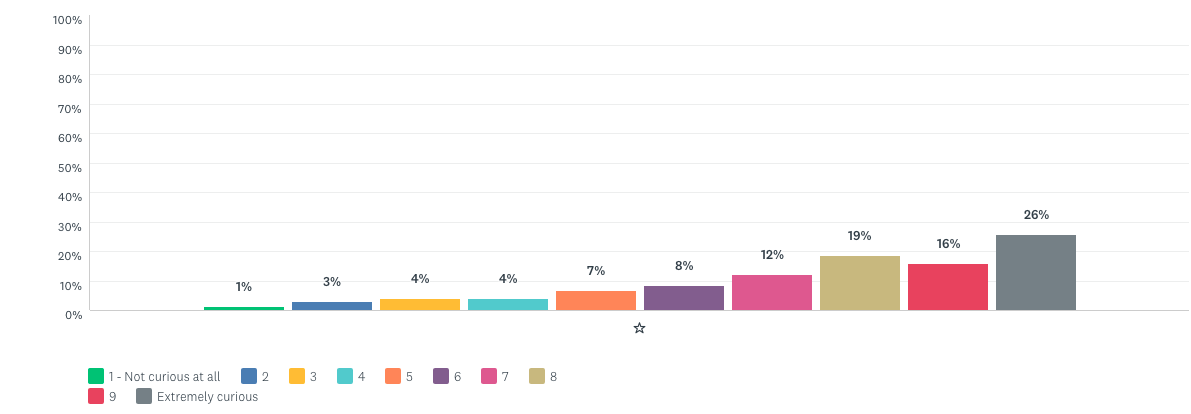

More than half of respondents (around 61%) indicated that there were somewhat to extremely curious about new techniques like DDMRP as an alternative to strive for forecast improvement. The majority of those reporting interest in DDMRP in a supply chain role (50%) and 20% are in sales. Many of them in the chemicals, consumer goods, food and beverage and manufacturing industry.

A new day for demand forecasting?

With ongoing challenges like coping with seasonality and far-reaching geopolitical shifts on the horizon, it’s not surprising to see that professionals are relying on several techniques to improve their demand forecasting process and cope with sudden changes in demand. Many are also investigating relatively new ones, like machine learning, and are also curious about DDMRP.