How Disruptions like Coronavirus Test The Resilience Of Supply Chain Planning

As the Coronavirus outbreak develops into a pandemic, people and businesses alike are feeling its ripple effects. Manufacturers like Hyundai are experiencing a shortage of components that threatens to halt production. Logistics providers like Maersk are forced to announce blank sailings due to curtailed demand. Avenues of transport are declining as major cargo airlines, like Cathay Pacific, drastically reduce flights to mainland China and Hong Kong. With shipments halted, e-commerce and retail firms also find themselves bracing for a substantial dip in sales. The virus continues to compromise supply chains and disrupt companies at a troubling rate, but are businesses prepared from a supply chain planning perspective?

First reactions to the outbreak

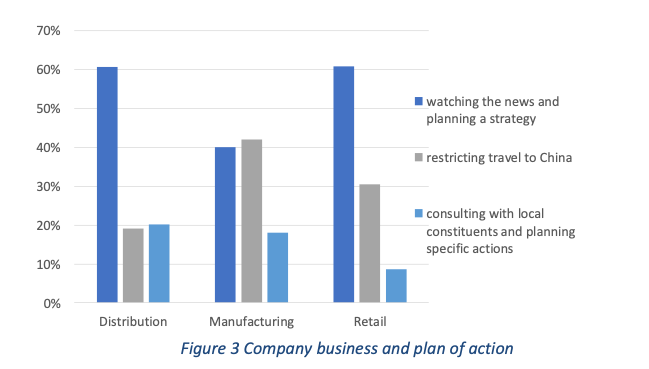

The era of globalization has enabled supply chains to be broader and more connected. While this creates tremendous value, it also brings the inevitable risk that certain events can have far-reaching consequences that influence supply chains more than ever before. As a result, the resilience of supply chain planning is being called into question. A recent online survey conducted by MIT’s Center for Transportation & Logistics aimed to understand how companies are reacting to the Coronavirus outbreak. The study included firms in the retail, manufacturing and distribution verticals. It found that 61% of respondents in distribution and retail, and 41% of businesses in manufacturing are largely in wait-and-see mode as they watch the news and plan for a strategy. Although 42% of manufacturers have restricted travel to China, there is far less emphasis on planning–specific actions as businesses hope to be able to deal with issues as they arise.

The resilience of supply chain planning is being called into question. – Tweet this

How companies are thinking about disruption

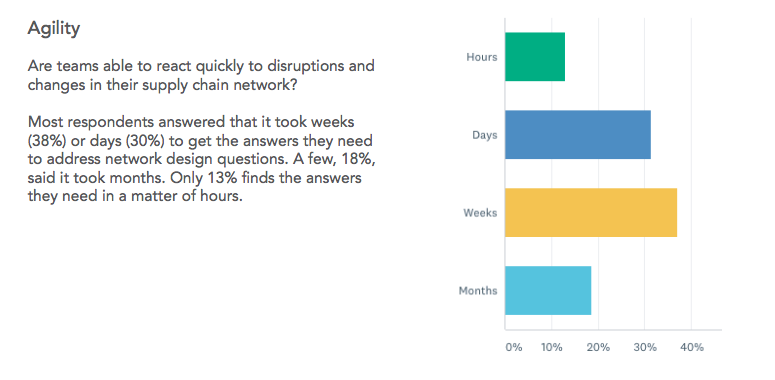

Natural or man-made disasters lead to disruptions that affect the entire distribution system and force reactive decision making. However, many firms have struggled to proactively put themselves in a position where they can be responsive to such changes. We often don’t read signals fast enough and cannot produce the answers we need quickly. Research conducted by AIMMS found that 38% of supply chain professionals require multiple weeks to address their network-related questions. 30% of respondents achieve answers within days. For some, it could even take months. In a situation where agility is essential, risks are not being addressed within an acceptable time.

What it takes to become a resilient organization

What it takes to become a resilient organization

Resilience is at the heart of supply chain planning, and understanding when and where to invest in resilience can lead to supply chains that quickly respond and recover from costly disruptions. Gartner recommends changing the supply chain planning paradigm from deterministic to resilient by using new technologies (see: Gartner’s “Mastering Uncertainty: The Rise of Resilient Supply Chain Planning“). At the same time, businesses must make faster predictions by leveraging cloud platforms and simulating their physical supply chain.

The prescriptive supply chain applications developed by AIMMS are at the forefront of enabling this shift. Network Design tools that are fueled by powerful mathematical optimization in the back end, and intuitive scenario analysis capabilities at the front, empower supply chain professionals with the ability to create flexible plans and expose hidden risks in their network. Demand simulations can highlight strategic warehouse, plant and supplier locations and test the robustness of strategies under different growth expectations. Furthermore, executive comparisons and sensitivity analyses, that combine detailed results with clear visualizations, allow users to evaluate multiple scenarios together. This leads to insightful and resilient thinking.

Network Design tools that are fueled by powerful mathematical optimization in the back end, and intuitive scenario analysis capabilities at the front, empower you to create flexible plans and expose hidden risks in your network. – Tweet this

Resilient planning in action

AIMMS SCNavigator applications have enabled resilient planning to take shape both reactively and proactively. Let’s explore some examples.

One of our chemical customers uses AIMMS S&OP Navigator to balance their supply and demand while maximizing EBITDA, performing risk assessments and evaluating scenarios, subject to multiple targets and constraints. Unexpectedly, a breakdown in one of their plants caused a serious production issue which required quick, reactive decision making. With S&OP Navigator, they could swiftly simulate the impact of reduced production on their supply chain. By dynamically adjusting capacities and utilizations within the app, they were able to optimally reallocate volumes and develop a new production and distribution plan. All of this was done within an hour, with the management team interactively reviewing multiple scenarios during a meeting – an activity that would have previously taken them at least 24 hours with more cumbersome and less interactive tools.

On the other hand, proactively designing a resilient supply chain requires evaluating future uncertainty, such as politically imposed tariffs or natural disasters like hurricanes. Most often, these events force demand and resource usage to fluctuate. The sudden changes create an unforeseen impact on the supply chain that can only be deciphered by means of advanced analytics. Using Network Design Navigator and its Mixed Integer Programming capability, companies can not only study their optimal network under differently constrained conditions and scenarios, but also simulate the impact of varying demand across the entire network. This allows users to examine when and where their network will effectively “break” and emphasizes locations in their network that might hold hidden value.

In one such analysis, we studied how the utilization of different distribution centers and cross–docs changes over time, as demand explodes by 5% in year one, 10% in year two and 20% in year three. While most warehouses experienced the same, or slightly increased utilization as the years progressed, one of the DCs saw its production double. A resilient supply chain leader might recognize the strategic importance of this location and begin ramping up its capacity to ensure that future uncertainty can be dealt with.

Ready to equip your team for resilience?

We live in an unpredictable environment and cannot control many of the events that affect our businesses. However, we can certainly equip ourselves with the right tools and technology to make ourselves more resilient. Designing a flexible supply chain and evaluating multiple scenarios not only reduces the risks posed by events like the Coronavirus outbreak, but also helps businesses leverage the strategic competitive advantages that resilience and preparedness provide. Contact us if you’re interested in building up your resilient planning capabilities and download this complimentary Gartner report to learn more.