4 Gartner® Insights for Supply Chain Network Design Success

Is your company looking to build a more customer-centric supply chain? Then you will probably embark on a new network design project to identify risk areas and opportunities. But it’s not uncommon for supply chain network design initiatives to stall. This is often due to poor stakeholder management, insufficient data validation and lack of trust. How do you avoid these common pitfalls? Before you dive into network design implementation, it pays off to develop a solid foundation.

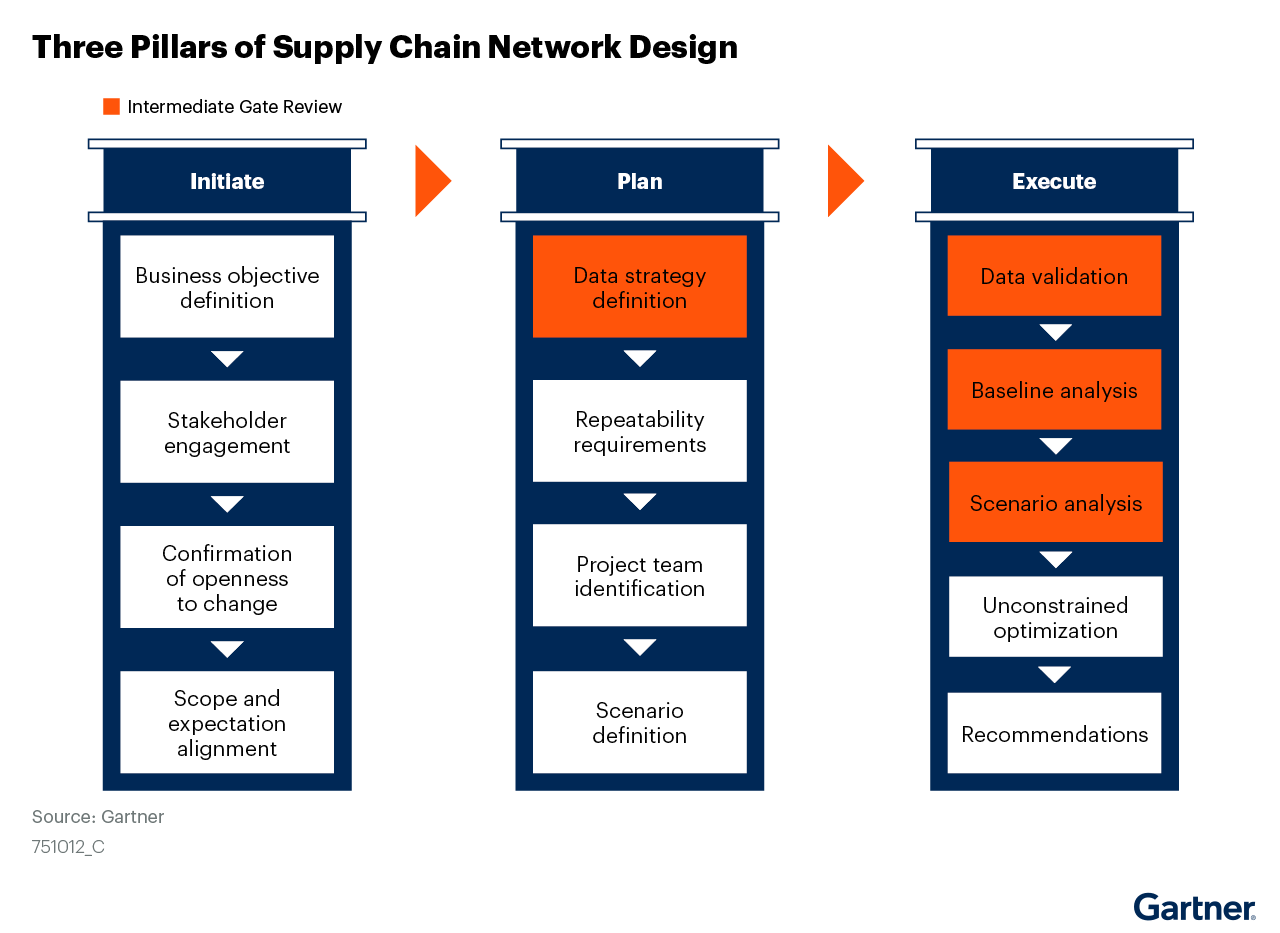

3 pillars for successful supply chain network design

In a recent 2-part report, Gartner analysts Kamala Raman and Vicky Forman recommend following a three-pillar framework to ensure success. You can get a complimentary copy of the second part of the report here. What are the biggest takeaways in the series?

Invest time up-front to scope out your project, involve stakeholders and set expectations

As a best practice, start with a clear objective. For example, what kind of changes can we make to increase resilience, and what’s the cost trade-off? Once you’ve identified the objective:

- Map the key stakeholders and involve them in the process.

- Make sure you’re all on the same page about the level of change that can be managed.

- Consider limiting your scope by geography or product line if it helps you focus the study.

- Define a realistic project timeline.

You’ll need to think about the nature of the objective or challenge: is it recurring or one-off? The answer to this question will determine your project timeline, and the effort required.

Almost all network design initiatives require specialized skills. You’ll also need to determine whether you have the internal know-how to execute this project or rely on external resources. Some software vendors like AIMMS offer hybrid service offerings, which may be interesting to consider if you don’t have the right (or enough of the) right skills in-house.

Define supply chain network design scenarios based on your objectives

If you have clarity on your objectives, scope and team, you can start thinking about scenarios. Start with a high-level definition of your scenarios to identify “the what ifs that need to be tested” (Gartner, Define Your Optimal Supply Chain Network Using 3 Pillars of Network Design: Part 1 – Initiate and Plan, June 14, 2021, Kamala Raman, Vicky Forman). The most important thing is that your scenarios are aligned with business objectives. For example, if your main objective is to lower costs, typical scenarios you can run include:

- Relaxing transport constraints to see if you can allocate customers to different service locations in order to optimize costs.

- Relaxing DC capacity constraints to see if you can shift volumes between locations to save costs. This will also reveal how much additional capacity you need to make these shifts, and whether it is worth the CAPEX investment to do this compared to the OPEX savings that can be achieved.

- Relaxing supplier and production constraints to see if any shifts in supplier and production volumes deliver any cost improvements.

Build trust with careful data and base case validation

Once you’ve defined the scenarios you need to run, you’ll need to determine which data you need to collect, and you’ll need to validate that data with your stakeholders. As a best practice, you should model your base case, which is a reference point from which you can measure optimization benefits. A “historic baseline” is the “most common form of baseline, reflecting what happened in the network during a past period for which there is data” (Gartner, Define Your Optimal Supply Chain Network Using 3 Pillars of Network Design: Part 2 – Execute, June 14, 2021, Kamala Raman, Vicky Forman). Gartner recommends that you validate the baseline with your key stakeholders and get sign-off before you move on to the next phases: optimization and recommendation.

Use optimization to uncover hidden opportunities

Mathematical optimization is a prescriptive analytics technique that helps you make decisions with confidence by providing recommended actions. Optimization can be used in a constrained or unconstrained way. Supply chain teams typically start with “constrained optimization,” which Gartner defines as “scenarios where real life limits on variables (such as service levels or capacity) are taken into account as explicit constraints on the model.” Its counterpart, “unconstrained optimization” places no limits on the variables. Often, you can slowly start relaxing different constraints to identify improvement areas. Our customers find it incredibly valuable to compare different scenarios, backed up by optimization, in order to find the best course of action.

Get more detailed tips and real-life examples in the Gartner report. Download your complimentary copy today.

Reports cited:

Define Your Optimal Supply Chain Network Using 3 Pillars of Network Design: Part 1 — Initiate and Plan, 14 June 2021, Vicky Forman, Kamala Raman

Define Your Optimal Supply Chain Network Using 3 Pillars of Network Design: Part 2 — Execute, 14 June 2021, Vicky Forman, Kamala Raman