Supply Chain Network Design Maturity and Implementation Models Post COVID-19

Until recently, supply chain network design was done on a case-by-case basis. For example, when the need to invest in a new distribution center came up. But trade sanctions, climate disasters, global pandemics…all of these disruptive events are pushing companies to revisit the frequency with which they review their supply chain networks. In part one of this series, we looked at the tools in use for supply chain design and explored the findings of our 2022 research, timed just after the world started recovering from the COVID-19 pandemic. This blog explores how supply chain network design maturity has changed. We will discuss whether companies are embracing more frequent network design assessments and sustainability trade-offs.

Typical use of supply chain network design

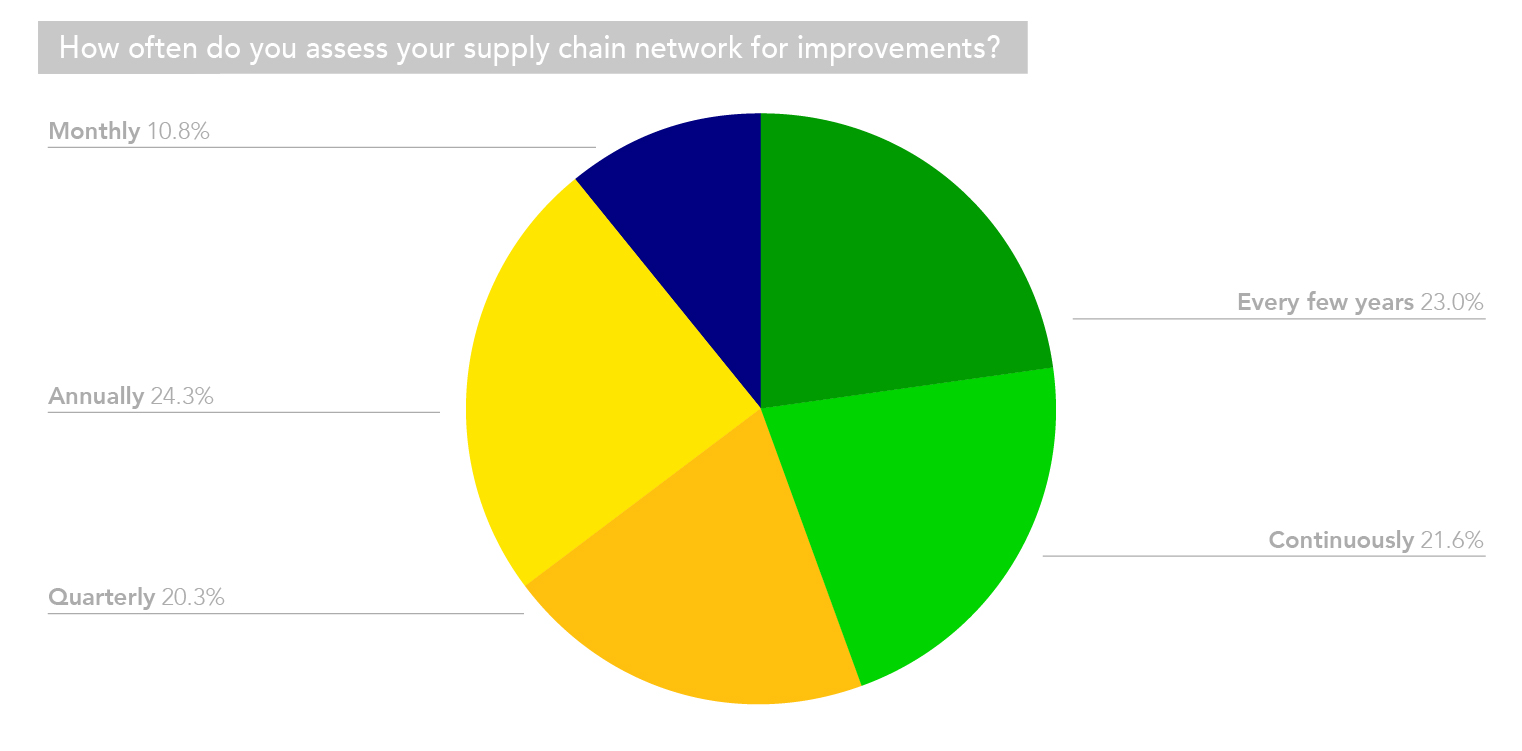

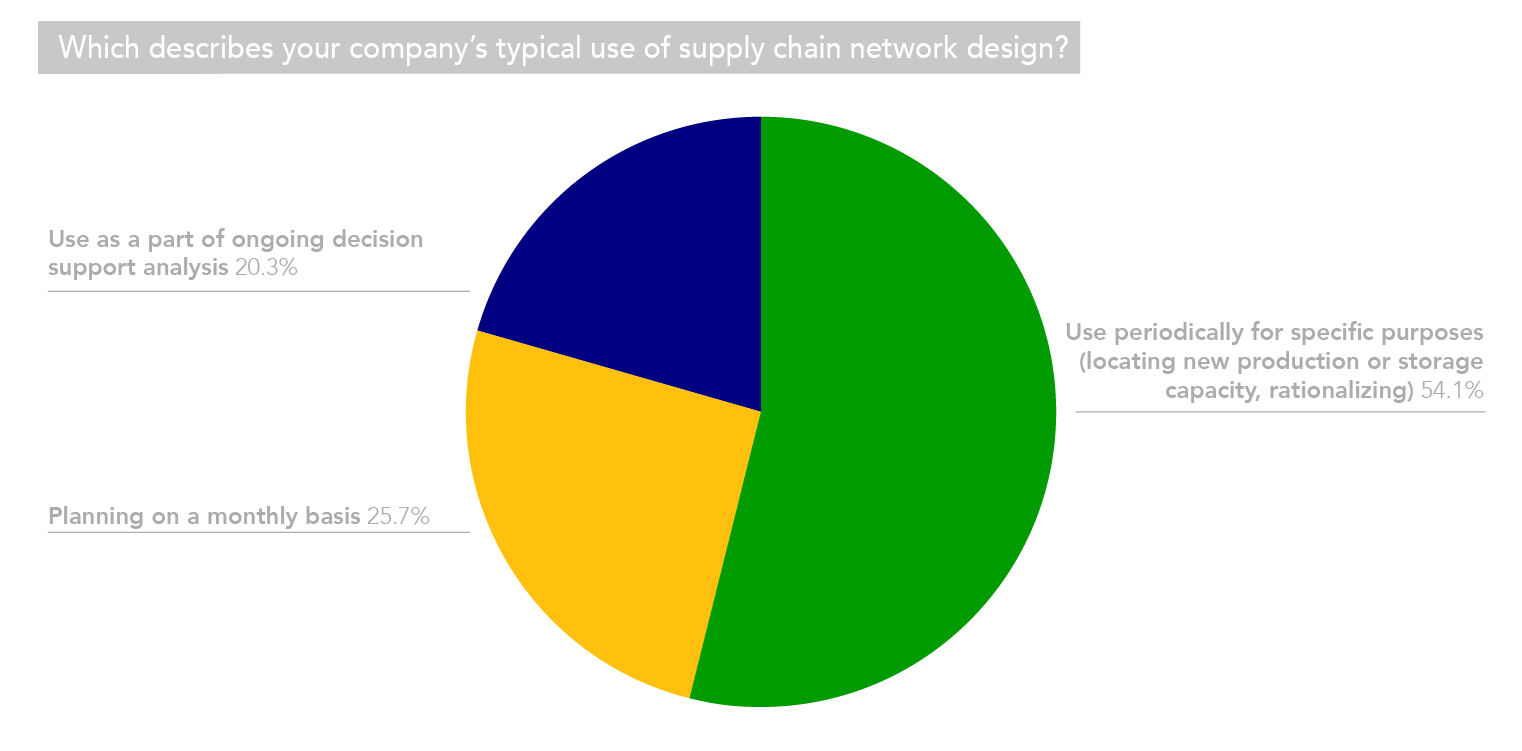

While network design was traditionally seen as a periodic activity, we do see some noteworthy changes compared to our 2019 (pre-pandemic) research.

More than half (54%) still perform supply chain network design periodically to answer specific questions like rationalizing their network, adding capacity, and so on.

We do see some improvement in terms of monthly frequency. In 2019, 18% of respondents told us they performed assessments in their network on a monthly basis. Today, a quarter of respondents (25%) do.

About 20% of companies are using network design as part of ongoing decision support activities.

In-house experience

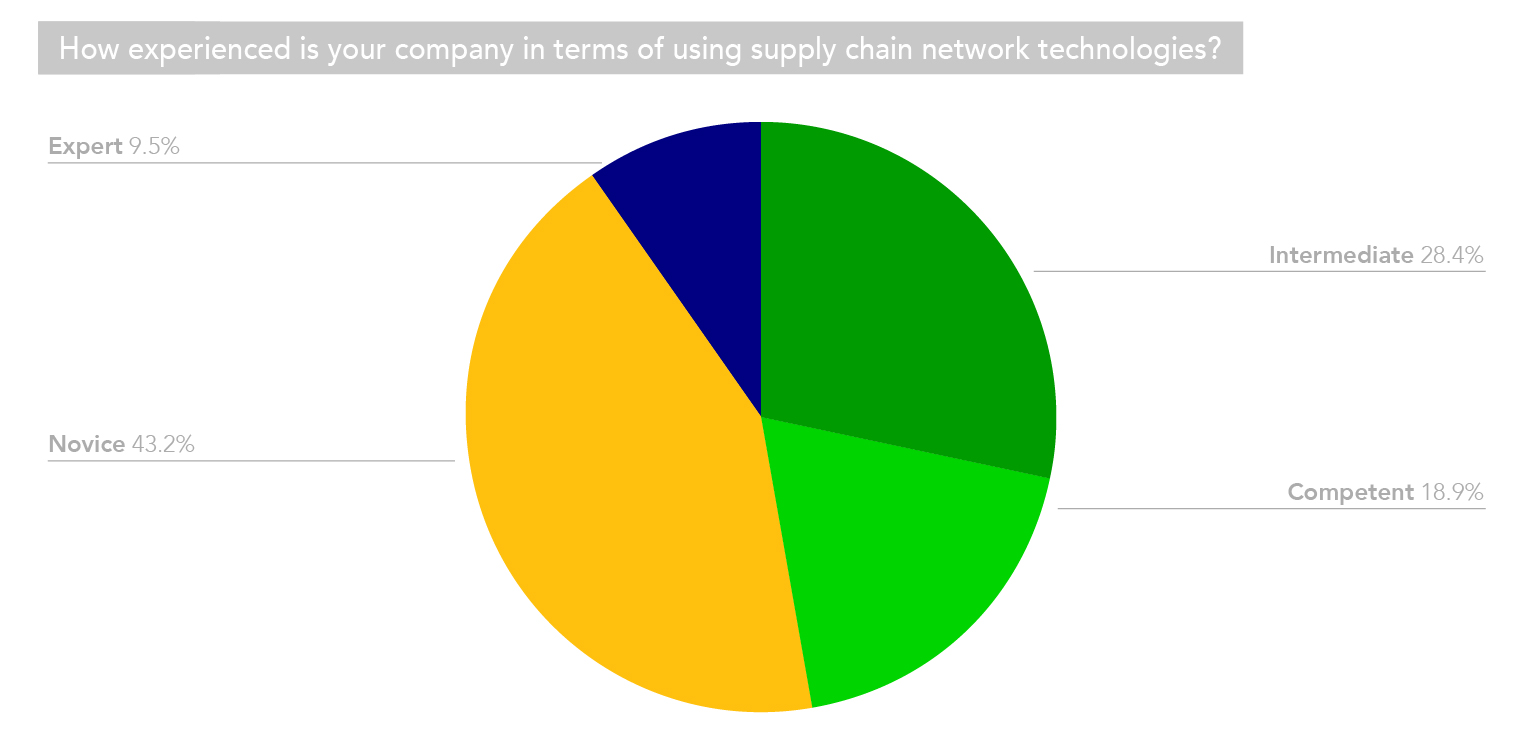

Most respondents would consider themselves “novices” in supply chain network design (43%), or “intermediate” at 28%. Less than 10% would say their company is an “expert” in the area, and nearly 19% say their company is “competent” at it.

This is similar to our 2019 findings where 40% said they were “advanced beginners.” Only 8% said they were “experts.”

Different maturity models require different implementation options

Given that companies have very different maturity levels and approach to supply chain network design, innovative delivery models are emerging. AIMMS, for instance, offers Supply Chain Digital Twin as a service, an option that allows companies to outsource the creation and maintenance of their digital supply chain twin and focus on ongoing scenario analysis and improvements.

A digital supply chain twin can help supply chain leaders use resources more effectively and make decisions that are better aligned with corporate objectives.

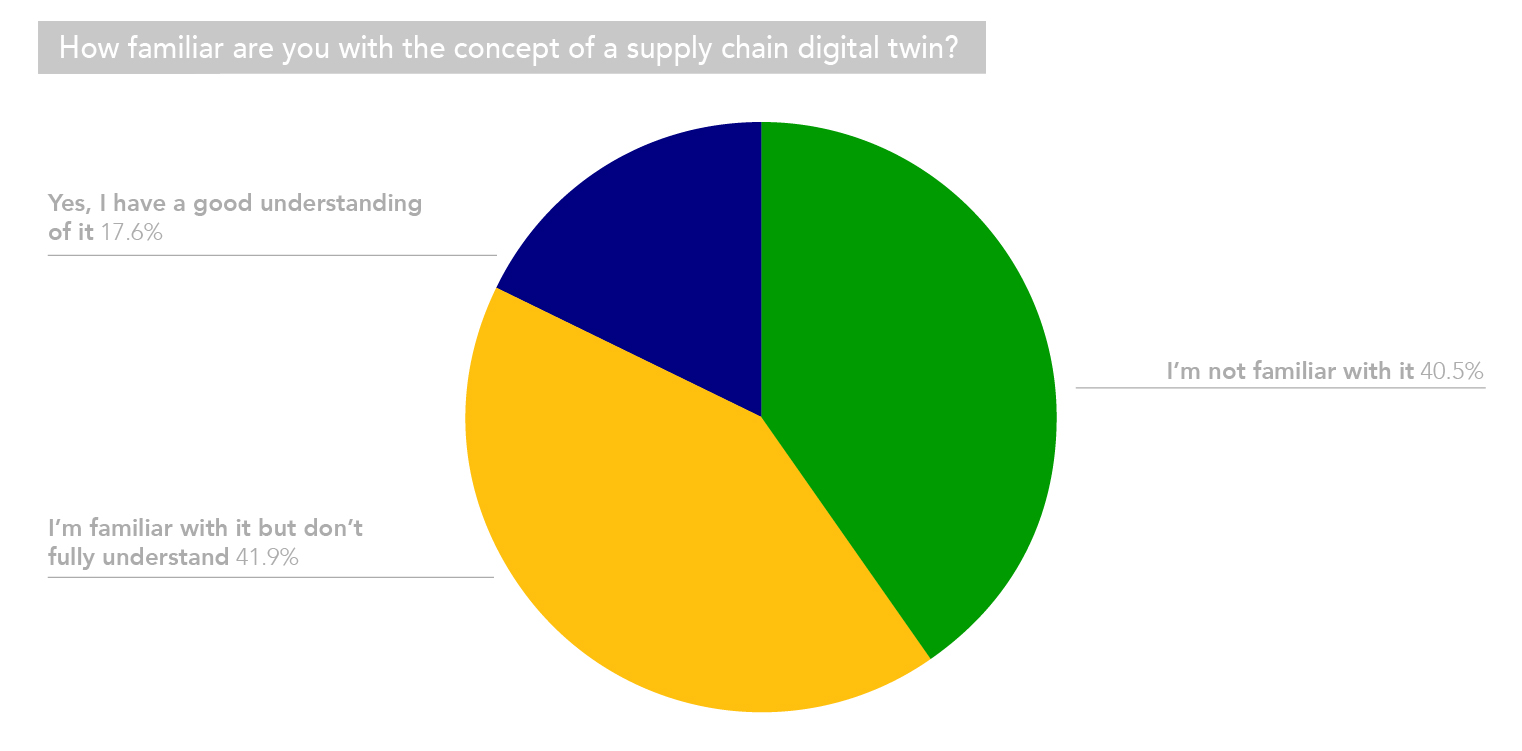

We polled the market to see how familiar supply chain professionals are with this concept.

The majority of people are either not familiar with digital supply chain twins, or familiar but without a full understanding of it. About 18% say they have a good understanding of it.

This is not surprising. Gartner first coined the term “digital supply chain twin” in 2018. Since then, there’s been a lot of confusion in the market about what it means. More education is necessary to foster market understanding.

Sustainability

Besides new delivery models like digital twin as a service, the increasing push for sustainability is driving another big shift in the market. The introduction of the Corporate Sustainability Reporting Directive in Europe means that companies will need to report on their emissions and set targets to reduce them. Supply chains are a big contributor to an organization’s carbon footprint. So, many forward-looking organizations are already looking to incorporate sustainability trade-offs in their network design decisions.

In the last nine months, the percentage of large global companies with net-zero targets rose from 20% to 33%. 52% of respondents in Gartner’s 2020 Sustainability Survey say sustainability is on their strategic agenda; 92% say sustainability spending is increasing. This is driven largely by rising compliance and policy demands.

Carbon emission modeling

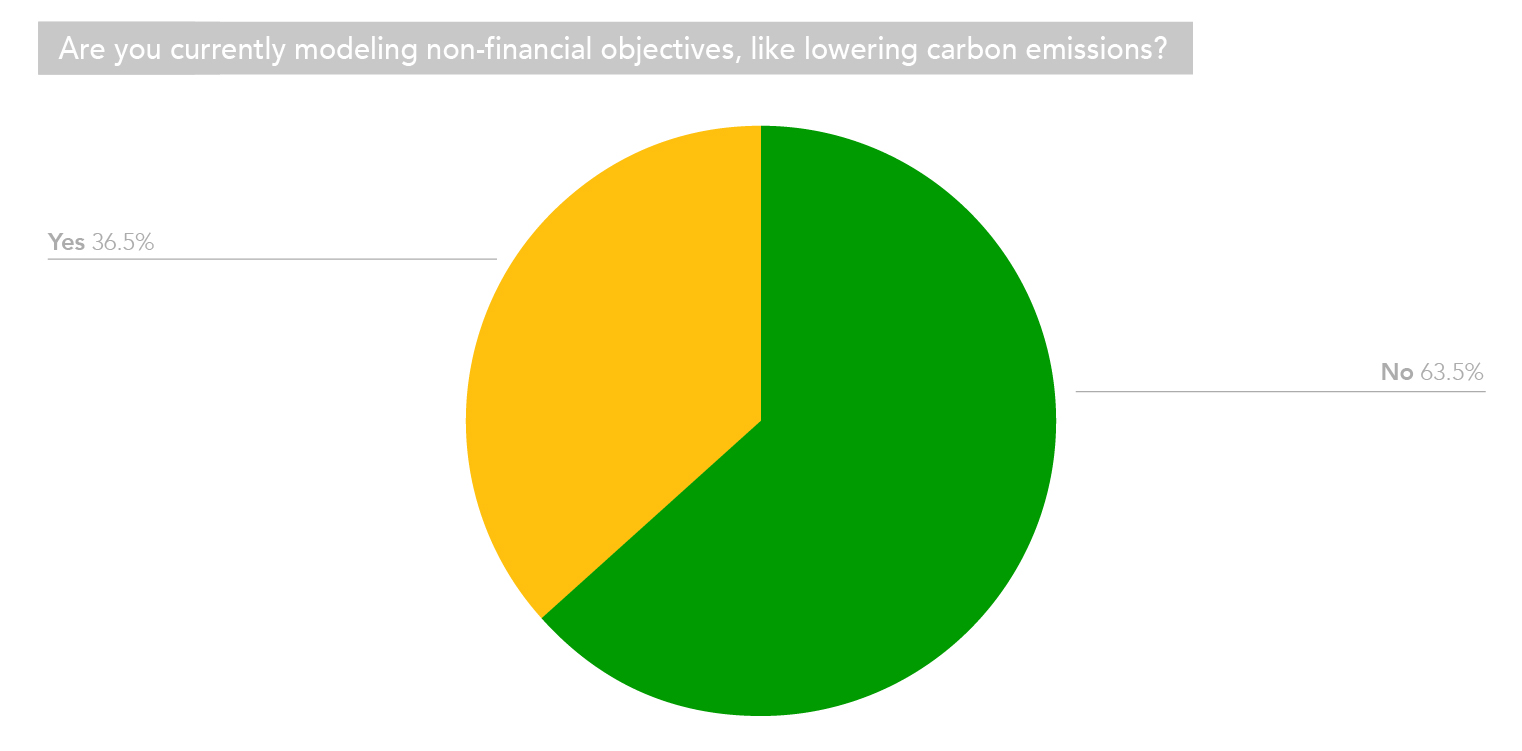

The majority of companies are not yet modeling non-financial objectives like carbon emissions. This may be because this data is not easy to collect and much more difficult to factor into network models using basic tools like spreadsheets (which are still used by over 40% of organizations).

Despite this, a surprising 37% of respondents are already modeling carbon emissions. We expect this number to increase in the near future.

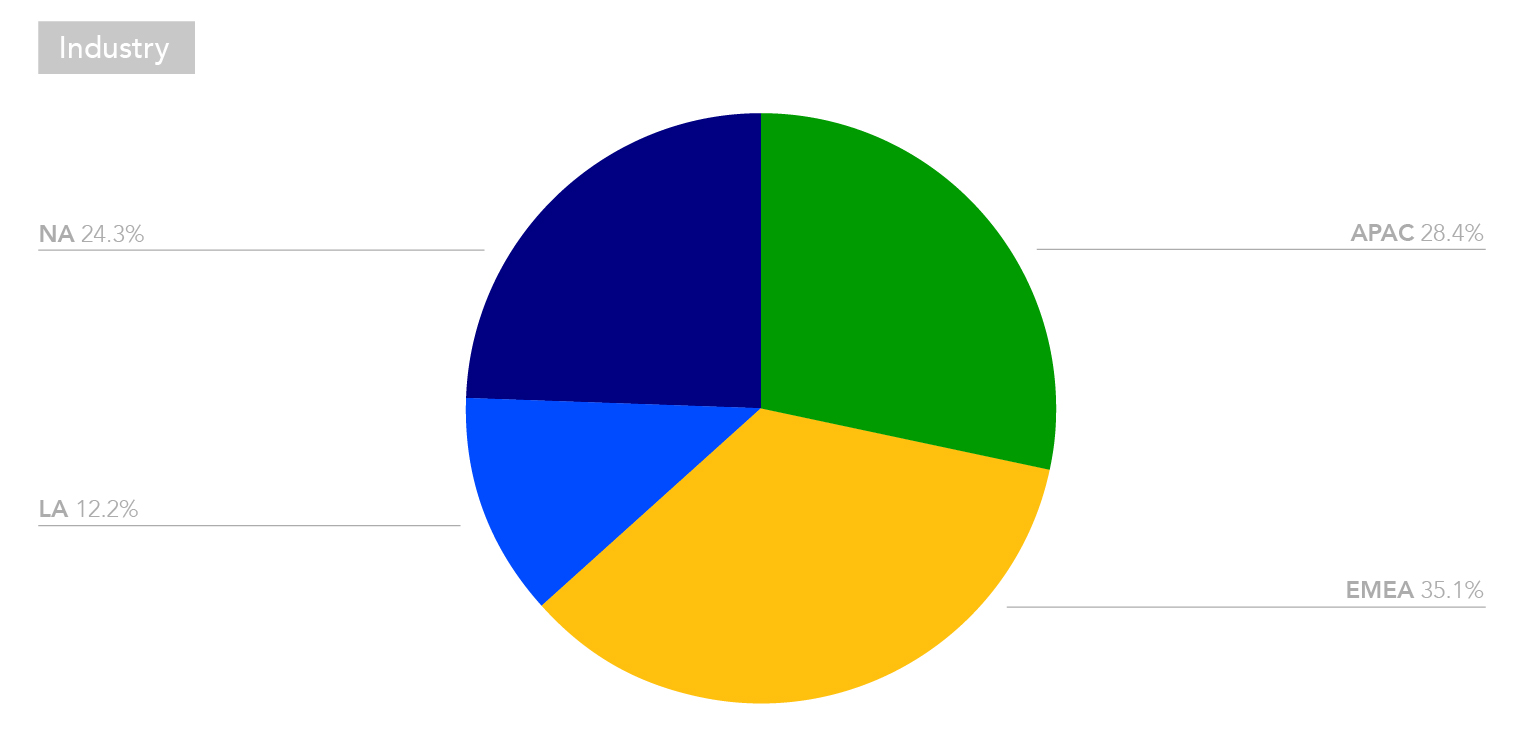

Most companies that are modeling carbon emissions are in EMEA, which is logical given that you have new sustainability regulations entering the picture. APAC is the next in line, followed by North America.

Besides becoming more sustainable, how are companies hoping to benefit from improving their network design capabilities?

The benefits of supply chain network design

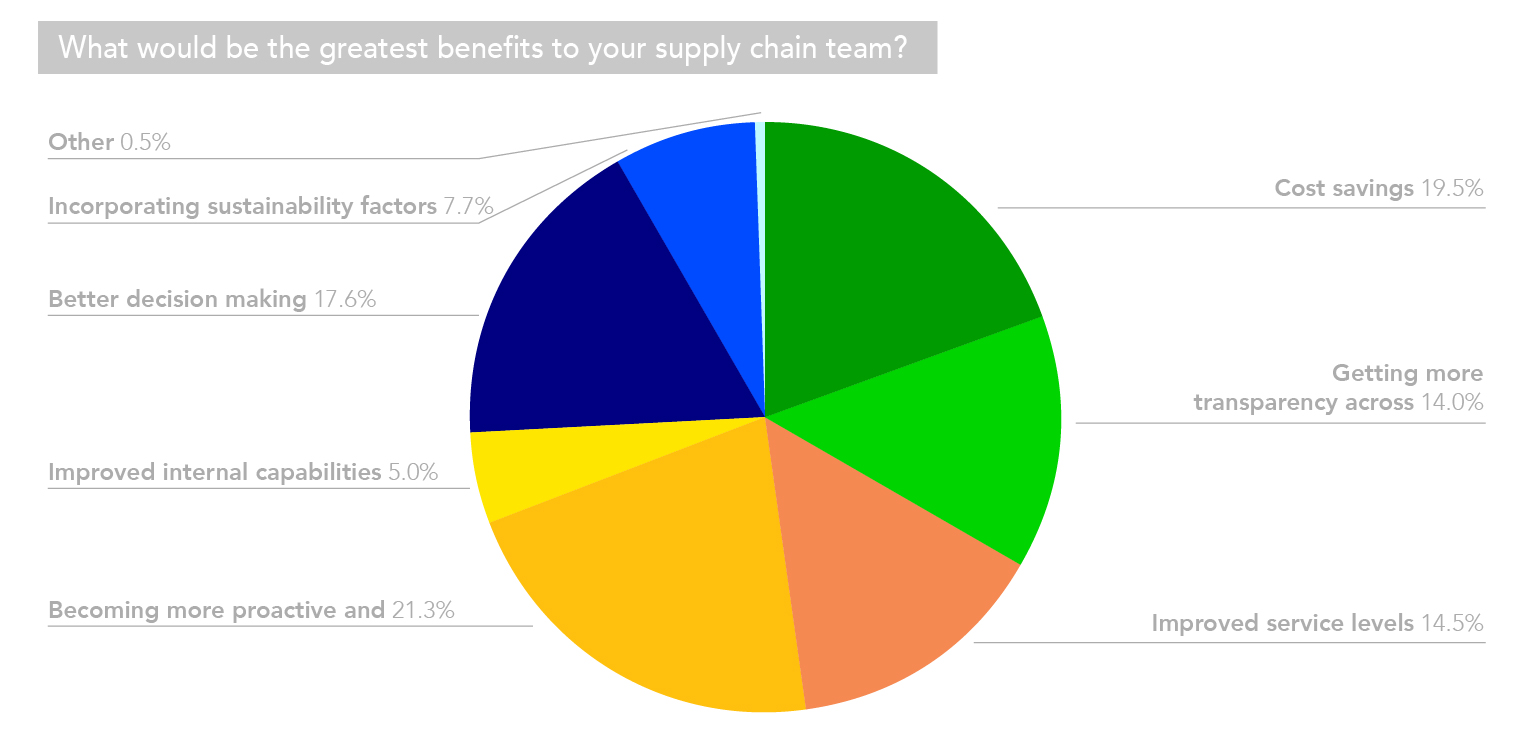

Most respondents say the ability to be “more proactive and less reactive” is what’s driving their network design efforts in terms of benefits. This is followed by cost savings, better decision making and improved service levels. Transparency is also a common benefit. Only 7.7% of respondents cite “incorporating sustainability factors” as a benefit.

Our conclusions

Supply chain network design is changing to meet the demands of this age of volatility but not all companies are moving fast enough to embrace this change.

Those who have a competent capability that provides answers to the business quickly are better positioned to be competitive.

If you want to become more proactive in supply chain network design, like many of our survey respondents, start by evaluating your current capabilities. Download the full report for more insights or evaluate technology options with our on-demand webinar.