The Changing Paradigm of Supply Chain Design

At AIMMS, we’ve recognized that if recent disruptions have taught us anything about the design of supply chains, it’s that – it’s not static. Supply chain design changes in response to shifting market conditions and unexpected challenges.

Unfortunately, despite design-altering events becoming more frequent and wide-ranging, companies have failed to react with any real conviction to keep pace with changing demands… until now.

The ripple effects of recent unexpected events have not only had an impact on the operation of supply chains but also on the mindset of supply chain leaders in organizations around the world. Suddenly, there has been a shift in attitude in terms of how businesses are approaching strategic network design.

Changing approach to Network Design ‘undeniable’

As a Network Design Implementation Specialist, I have noticed an undeniable attitude shift in how businesses approach strategic network design.

Whereas before, enterprises were using outdated tactics and datasets to analyze and re-engineer supply chain designs, more companies are becoming ultra-agile. This gives them the ability to revisit supply chain designs regularly and act before a large-scale disruption occurs.

Before we dive deeper into why the mindset of supply chain leaders has changed, it’s important to understand what is network design.

What is Supply Chain Network Design?

Network design is the practice of optimizing the size, location, and flow between the various points that form your supply chain. There are two key features of network design:

- Optimization – This is where an underlying mathematical model considers the various limitations – or ‘business rules’ – associated with your supply chain. The underlying model then presents you with the most optimal way to design your supply chain network.

- Scenario Planning – which is when the constraints and other aspects of your current model can be altered and the implications of changing them can be deeply analyzed, to help you make the best, most informed decisions to suit your supply chain.

You might be thinking, “Why is this Supply chain Network Design, isn’t it Network Optimization?”

Many people do call it network optimization. Personally, I like the word ‘design’ because it accurately implies that there is a little bit of art to this science.

Network Design forces you to look at your supply chain differently

Unlike many operational optimization models, where the optimized result is unquestionably executed, network design forces you to consider many different nuances of the consequence before implementing the recommendations.

The ‘what-if?’ question invariably arises when performing a network design study, putting further emphasis on the ability to easily model various what-if scenarios, and clearly visualize them.

The question for you is, why should you care?

Your company probably has several tiers of suppliers. Your tier one firms most likely supply you directly, while your tier two suppliers might supply your tier one suppliers, and so on. However, it’s perhaps the case that you don’t know what happens much beyond your second tier.

The more tiers that you have, whether it’s suppliers, production plants, warehouses, or other functions, the more supply chain network design matters to your business. The good news is that network design is a great way to enhance your supply chain visibility and better prepare your business for the future.

How does Network Design transform your Supply Chain?

1. Your supply chain is reviewed more regularly

One of the most notable changes network design gives your supply chain is that you can review it more regularly. What used to be done once yearly, or by outside consultants, can now be done in-house on a consistent basis – sometimes even once a month. This allows you to run scenarios proactively and reactively to help you prepare for disruptions.

Network design reinforces your supply chain by mapping and modeling processes, and then optimizing them to ensure that products and services are delivered on time and cost-effectively.

2. Specialized teams are positioned to analyze your supply chain

What used to be the job of a specialized person is now the responsibility of an entire team because of the growing complexities and interconnected nature of supply chain networks. For some businesses, supply chain design is a critical function and core process, helping to regularly rationalize their models as required.

With this in mind, more companies are now setting up dedicated network design centers operated by a cross-functional team that has the necessary skill sets and experience. Rather than one person having to manage supply chain problems, teams can plan the frequency and critical issues that should flag the remodeling of supply chain design and establish these rules.

3. Supply chain design reduces the reliance on Excel

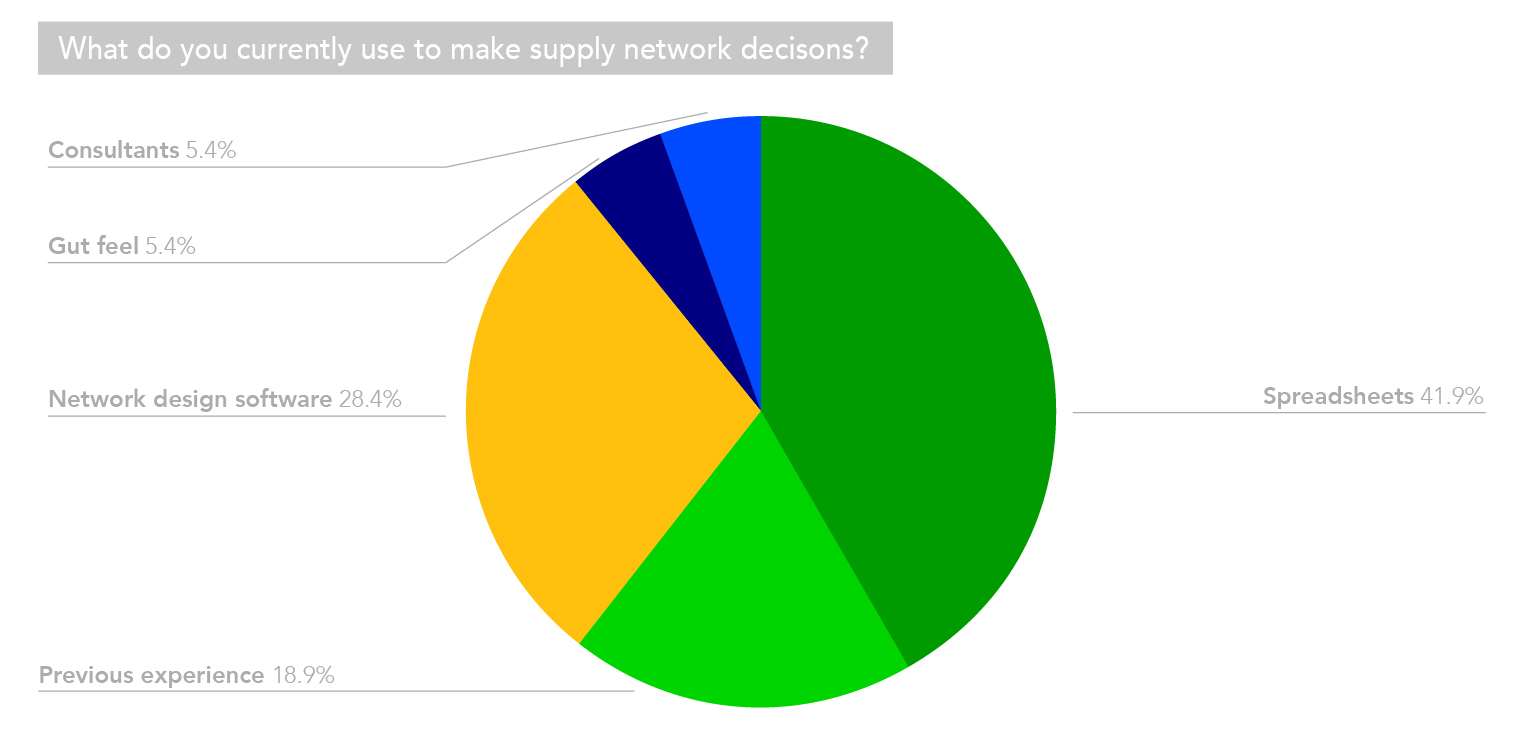

In 2019, we started offering a free assessment for supply chain professionals to evaluate their network design maturity. From our research in 2019, we learned that 41% of respondents used spreadsheets to run calculations for supply chain design decisions.

Fast-forward to 2022 and not much has changed. Spreadsheets are still one of the most predominant tools in the supply chain. We understand. After all, spreadsheets are convenient, familiar, and inexpensive. However, they are also highly problematic.

For starters, they are error-prone. Secondly, integration, collaboration, deployment, and support are limited with spreadsheets. Excel in particular is limited in terms of how it handles complex and large data sets.

While more organizations are moving away from spreadsheets toward advanced tooling, most companies are still not leveraging advanced analytics, which indicates that progress isn’t happening fast enough.

We’re not anti-Excel – far from it. It has served supply chains well over the years. However, the reality is that the supply chain is constantly shifting, and with it the need for specialized tools to manage the changing landscape.

Supply chain network design equips your business with a dynamic process that is better suited to the ever-changing conditions of the supply chain environment, markets, customers, suppliers, raw materials, and more.

How AIMMS can help you?

You need a technology that equips you to move from reactive to proactive decisions across your supply chain. That’s exactly what the AIMMS supply chain network design software gives you. Our network design software is driven by powerful mathematical optimization in the back end.

With our network design software, you can model your base case network and evaluate changes in your business environment to adapt quicker, all while quantifying optimization opportunities and backing up investment decisions with rock-solid data.

See for yourself how AIMMS SC Navigator can help you make the best supply chain decisions.