Electronics & Components Businesses

Many electronics companies face significant challenges in securing the components and materials they need to manufacture their products. This is causing serious delivery issues in their sales channel.

To address these challenges, businesses are turning to supply chain design and optimization solutions to improve visibility and control throughout their supply chain.

Trusted by supply chain teams at leading global companies

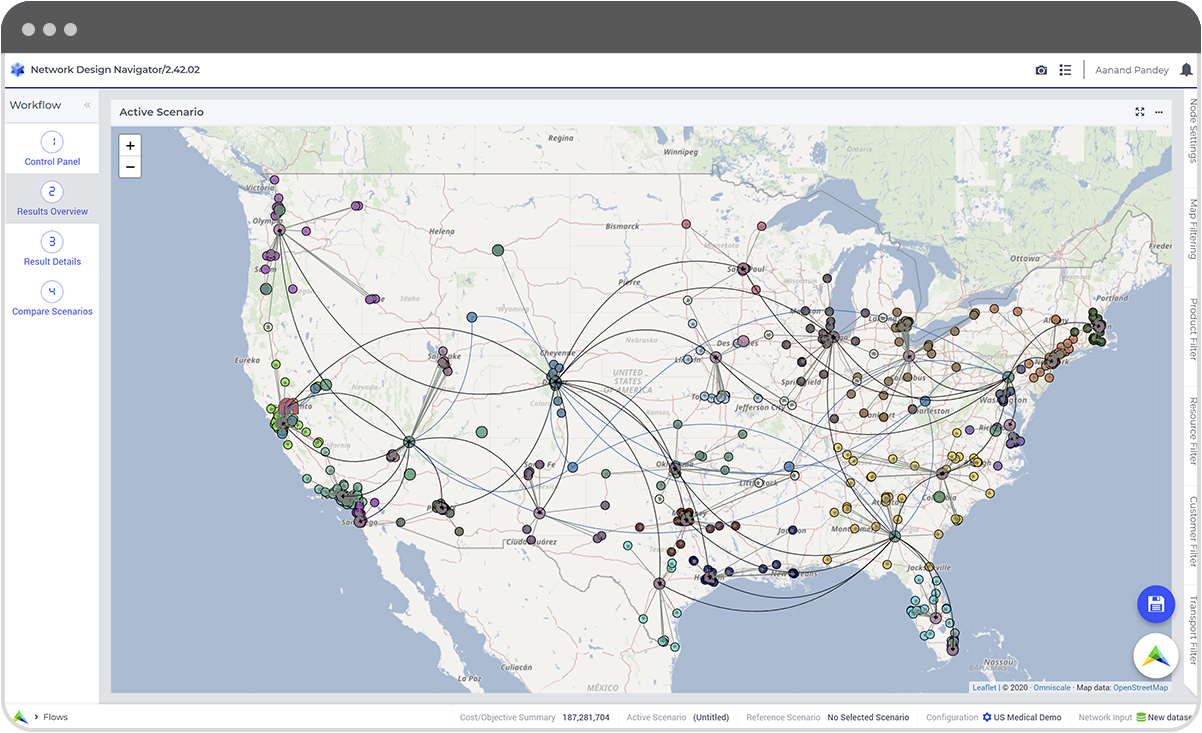

Supply Chain Network Design

SC Navigator is an off-the-shelf scenario planning and analytics app that helps teams make optimal supply chain design and tactical planning decisions based on hard data.

– Easily visualize and understand your current supply chain

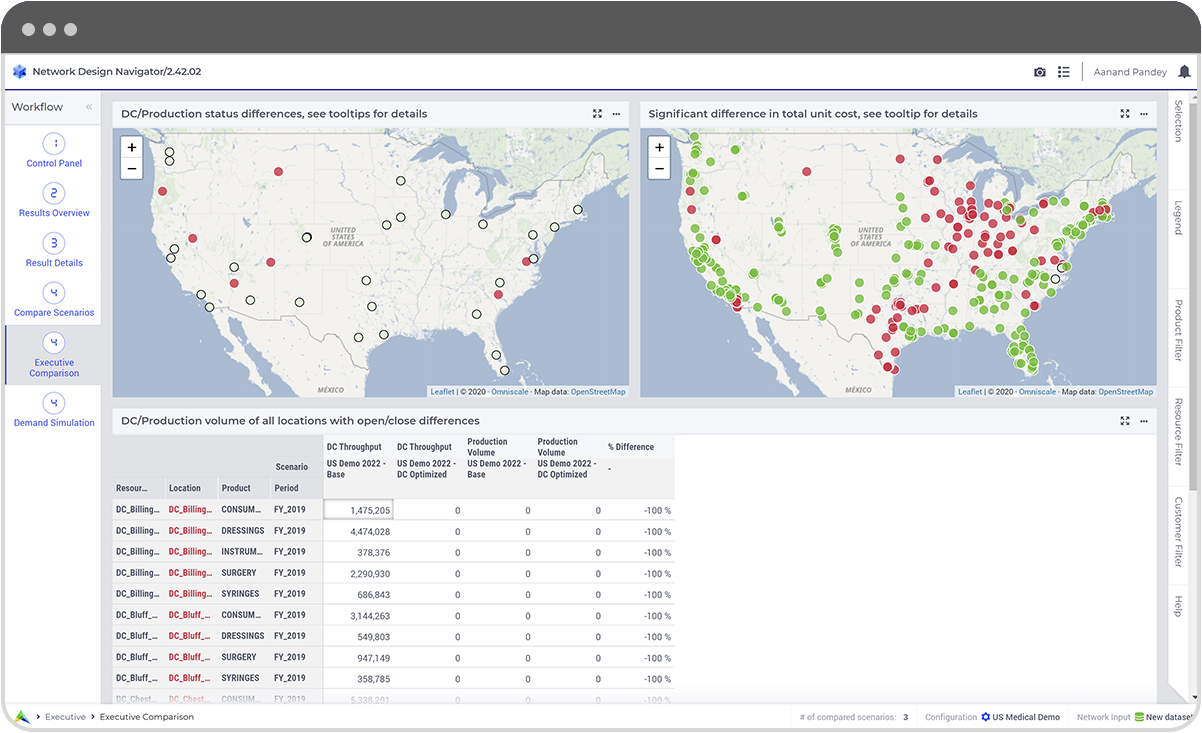

– Test countless scenarios and create optimal designs

– Identify critical trade-offs

Bespoke Optimization Apps

The AIMMS low-code platform is a toolkit for rapid modeling and app development of mathematical optimization applications.

– Model any business and research problem

– Run countless scenarios in realtime

– Create modern web-based user interfaces

– Complements AI/ML

Complete projects within weeks, not months

“With AIMMS, the time saving is around 50%. Because the baseline data is available, we don’t have to pull that data, so that’s an improvement versus a manual perspective.”

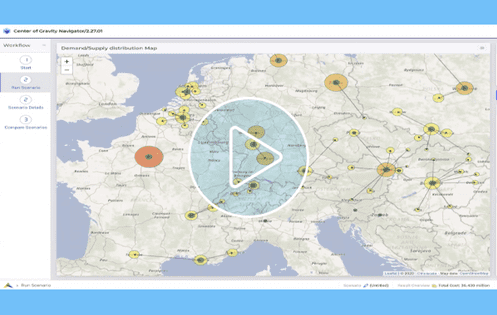

Managing global supply chain complexity with sourcing from multiple locations

With AIMMS, you can build multi-echelon network designs while modeling the detailed constraints and costs of your nodes along the way. In AIMMS Network Design, there is no limit to the number of locations you can model so that you can optimize complex networks and build resilient supply chains.

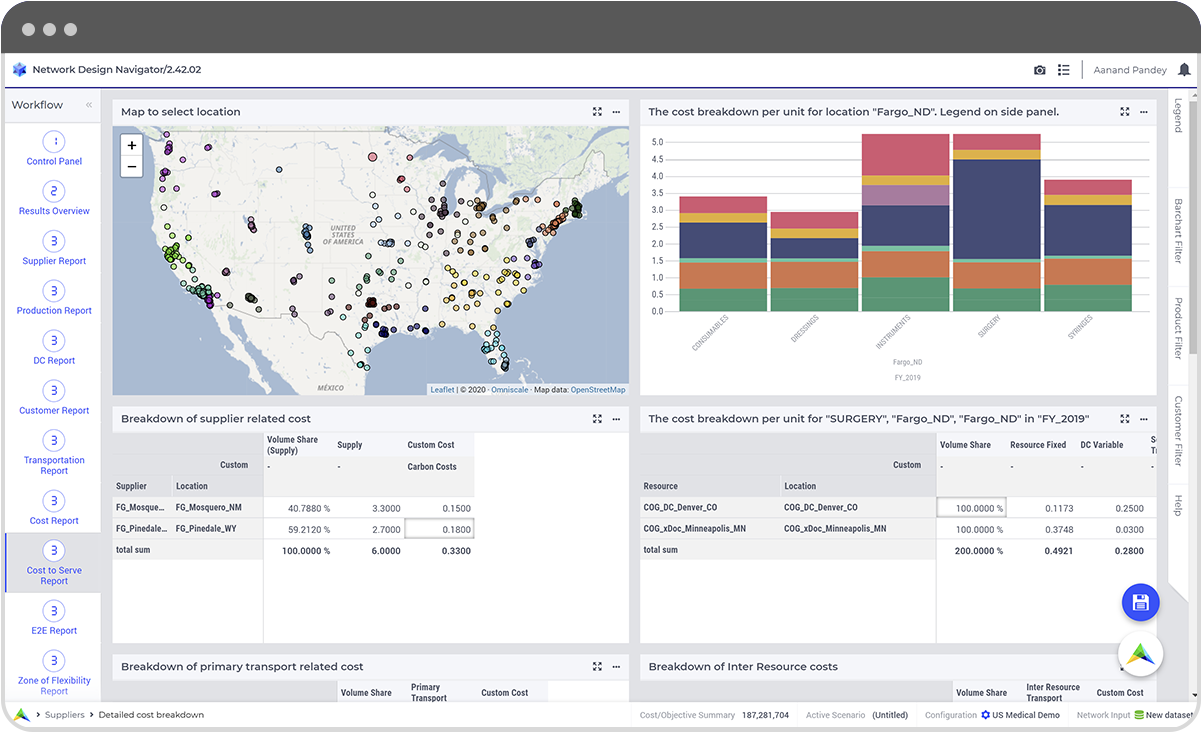

Managing short product lifecycle to meet demand changes and product discontinuation

With AIMMS, you can quickly add or remove products from your mix, and evaluate the best way to consolidate and flow your products throughout your network based on their costs, selling price, and profit margins. The app also allows you to dynamically create and run multiple demand scenarios to evaluate the impact changing demand will have over time.

Managing the ‘bullwhip’ effect in your supply chain

The bullwhip effect in your supply chain can lead to inventory imbalances caused by fluctuating demand, resulting in excess inventory or stockouts. AIMMS can help by taking a multi-period view of the future, planning against different demand scenarios, and understanding how you can mitigate this challenge by optimizing customer fulfillment decisions, decisions on where and by how much to ramp up or down supply capacity, and how to balance inventory into the future given your current and desired inventory positions.

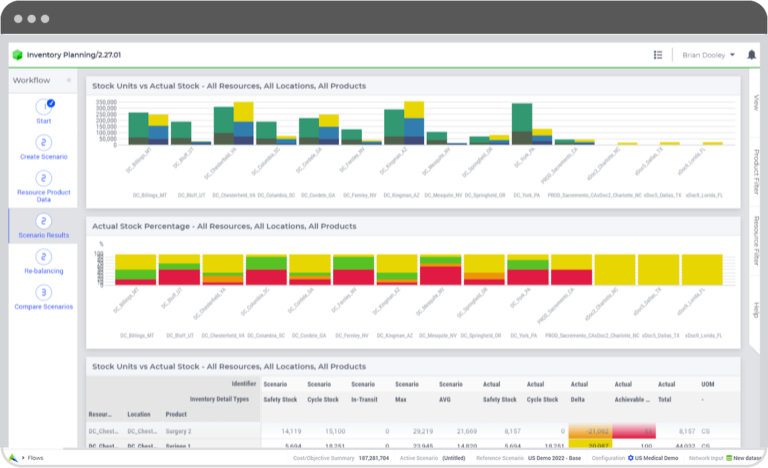

Managing inventory and reducing shipping costs due to high-volume and low-value products

With AIMMS, you can quickly identify the optimal safety stock, in-transit stock, and cycle stock at each of your stocking locations based on any given network scenario. AIMMS Inventory Planning will also help you understand how to rebalance your stock so that your service levels are not compromised. With each of these scenarios, your end-to-end network costs (including shipping) are also being optimized.

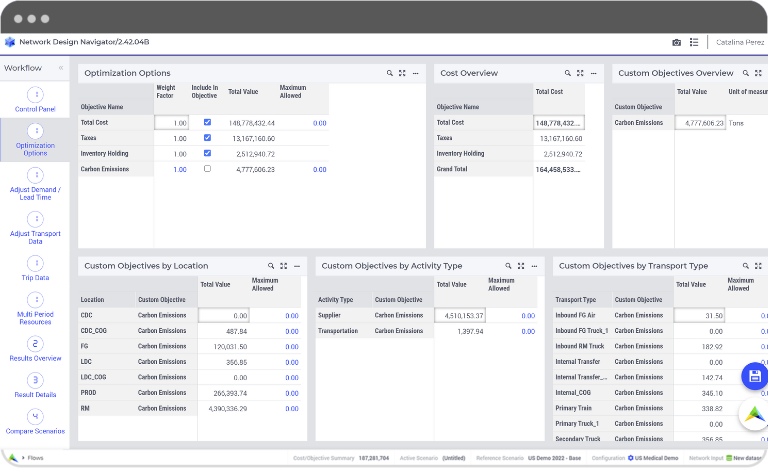

Managing sustainability and environmental impact

With AIMMS, sustainability metrics can be evaluated and optimized, and their cost and service level trade-offs can be measured. You can add carbon emissions, water waste, supplier risk index, or any other sustainability metric through the custom objective functionality and optimize your network based on your targets. Each scenario’s end-to-end impact on your entire network is also evaluated.

Here's how our solution helped other customers

“AIMMS allows us to quickly answer very specific questions affecting our business. The benefits of optimizing our business based on those answers will fund the use of AIMMS prescriptive analytics for many years.”

“Running scenarios with AIMMS SC Navigator saved us hours in time compared to other network design tools, as less data is required. It is easier to upload data and as the outcomes are structured better, they are easier to understand. The SaaS platform also allows to share the scenarios with other stakeholders and make the best decisions”

Supply Chain Digital Twin for World's Largest Semiconductor Chip Manufacturer

Know how the company diversified its supply chain with a new factory investment and shifts from ‘Just-in-Time to Just-in-Case’.