How to Boost Resilience in Multi-Tier Supply Chains?

Supply chain networks have become more complex and globalized over the years, making them more vulnerable to disruptions. The COVID-19 pandemic, natural disasters, and political instability have highlighted the need for resilient supply chains that can withstand unexpected events. One of the ways to increase supply chain resilience is through multi-tier supply chain network design.

Know why supply chain design tools are essential to boost resilience.

Multi-tier supply chain network design refers to the process of designing a supply chain network with multiple levels of suppliers and distributors. This approach creates redundancy and reduces the risk of disruption by spreading out the supply chain across various locations and suppliers. In this blog post, we will explore the impact of multi-tier supply chain network design on adding resilience to global supply chains.

Pandemic-triggered trends

Research has shown that supply chain disruptions are becoming more frequent and costly.

According to the BCI’s Supply Chain Resilience Report 2023, the level of supply chain disruption reported by organizations is still more than twice as high as pre-pandemic levels. Almost half of the respondents (45.7 percent) on their survey experienced these issues with their closest suppliers at Tier 1, while 24.1 percent saw more disruptions at Tier 2.

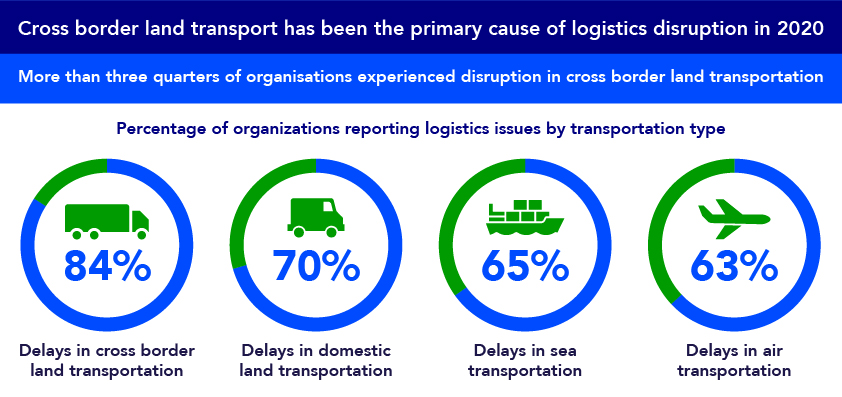

Transportation has been the focus for most global businesses due to its disruption during times of uncertainty, as seen below in the 2020 report.

The report also found that organizations with mature supply chain resilience programs were more likely to recover from disruptions quickly and effectively. These organizations had a multi-tier supply chain network design, redundant suppliers, and contingency plans in place.

However, the report signals that there is plenty of room for improvement, especially due to a lack of trust in technological solutions. On the question, do you use technology (e.g., risk analytics indicators) to record, measure, and report on performance-affecting supply chain disruptions?”, 55% of decision-makers surveyed answered negatively.

Furthermore, a McKinsey survey showed that less than half of the companies understood the location and risks of their tier-one suppliers, and only 2% had visibility beyond the third tier. This is important because supply shortages, such as semiconductors, often occur in these deeper tiers.

Solutions rely on trust, data, and technology

What can be considered as best practices for supply chain decision-makers? We’d stress these:

- Gathering data on the historical performance of your suppliers;

- Weighting resilience scores in the contract analysis process;

- Running scenario modeling and multi-objective optimization for your supply chain network design;

- Embedding business continuity requirements into contractual arrangements, using resilience as a distinguisher in contract awards.

40% of organizations incorporated supply chain mapping to varying degrees in their operations, with a significant number attributing their decision to the impact of COVID-19, again data coming from BCI. Leaders previously failed to recognize that backup suppliers ultimately sourced from the same region. With various regions experiencing delivery challenges at different stages of the pandemic, these organizations were unable to access crucial supplies.

Supply chain optimization technology plays a critical role in designing and managing multi-tier supply chain networks. These technologies use analytics, simulation, and optimization algorithms to help organizations make informed decisions about their supply chains. For example, these technologies can help organizations identify the optimal number and location of suppliers, as well as the optimal inventory levels and transportation routes.

As a result of a greater interest in their supply chains, more organizations are now reporting they have business continuity arrangements in place to deal with supply chain risk with four in five organizations as part of the contingency plan.

Decisions on supply chain tiers

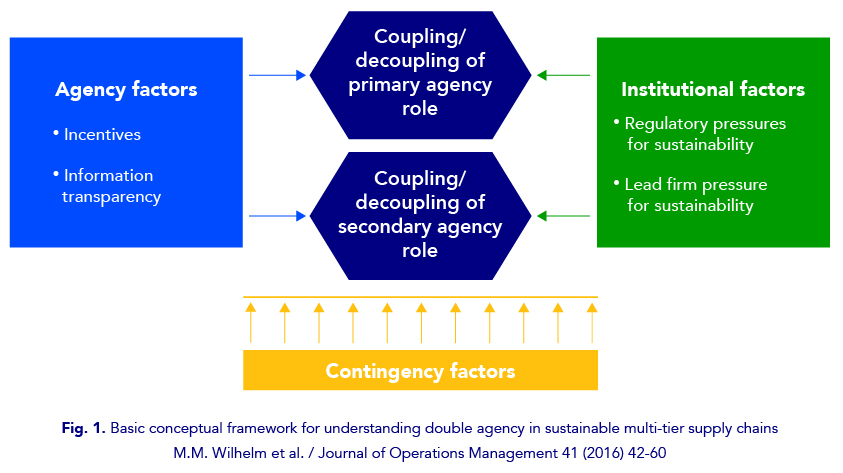

Dr. Miriam Wilhelm from the University of Groningen gives a great framework on how to treat multi-tier supply chains at organizations that have resilience and sustainability as priorities.

Sub-suppliers, rather than direct suppliers, are responsible for the most serious environmental and social breaches. However, lead firms struggle to manage sub-supplier sustainability due to limited information and control. This framework aims to explore the first-tier supplier’s role as a disseminator of sustainability standards to their customers and discern the conditions under which they comply with lead firms’ requirements. Agency theory and institutional factors are used to understand the double agency role of first-tier suppliers in a three-tier supply chain.

To conclude, multi-tier supply chain network design can help organizations add resilience to their global supply chains. This approach creates redundancy and reduces the risk of disruption by spreading out the supply chain across different locations and suppliers.

If you are interested in learning more about multi-tier supply chains and what they can do to make your business more resilient, please contact us and we will be happy to help you.