Maturity Scan

How mature is your S&OP process and how can you improve it?

AIMMS and ORTEC have teamed up to help you identify next steps in the maturity of the S&OP process. You’ll get your outcome and the corresponding advice right away. The complete assessment will take less than 5 minutes.

Scenario planning for S&OP

S&OP has become the preferred method to facilitate clear and formal communication between the demand and supply sides of a business. However, one-third of SCP leaders cite “the lack of effective decision making in the S&OP meeting process as the most critical problem to solve for their function’s overall performance” To address this, Gartner advises organizations to adopt scenario planning for S&OP.

source: Gartner, Improve S&OP Decision Making Through Scenario Planning, Supply Chain Research Team, 4 May 2020

Leveraging Scenario Planning for S&OP Decision Support

Compelling business benefits of S&OP

On-time product delivery

Improvements between 10-40%

Inventory levels

Decreased up to 70%

Downtimes

Went down between 20-50%

Plant efficiency

Improved up to 33%

Transport costs

Decreased up to 30%

Our customers see ROI

Within 6 to 24 months

Learn more

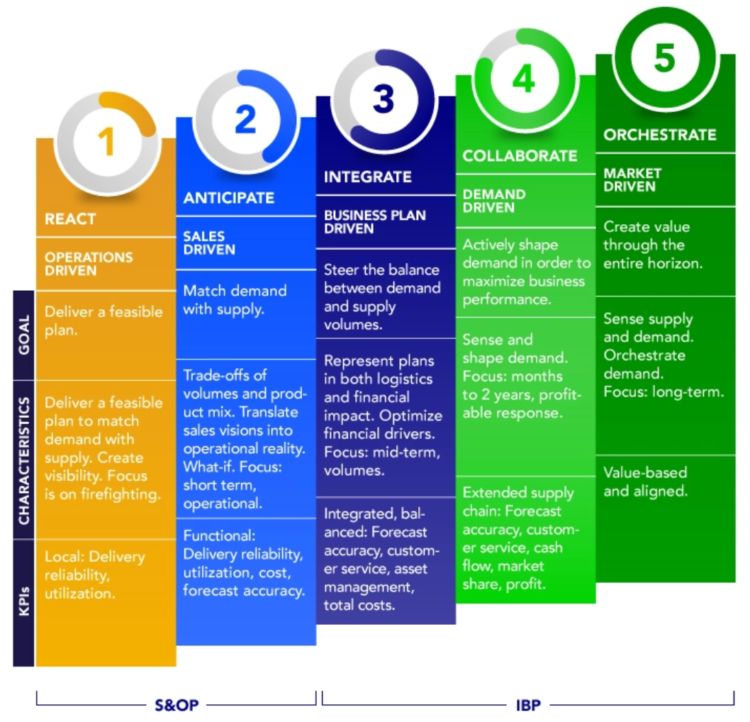

Based on the complexity and size of chemical companies, we’ve seen that most of them have achieved level 2 in S&OP maturity (out of 5 maturity levels). Most companies fail to reach level 3, due to alignment issues.

These are many issues that arise when teams don’t have a centralized S&OP workflow and common access to data. For example, teams in different regions typically have different ways to forecast demand. In such cases, it’s hard to align the team around a common source of truth. This makes it difficult to steer towards the desired strategic goals and to align operational activities like production planning.

Let’s take an example of a large fiber manufacturer. This company has a complex set of choices to make when it comes to deciding which products to manufacture. For instance, they didn’t have a clear view on the products with the highest margin, based on feedstock and operational expense. Due to poor internal alignment, some of their plants were also working overtime while others were significantly under-utilized. Plants that were pushed to the limit did not get enough time to carry out maintenance, so they suffered from high shutdown rates. Operating units used their own demand forecast; they had no centralized approach and saw frequent inventory violations. To make matters more complex, different departments also used their own method for estimating product costs. They had no centralized purchasing process. This resulted in high inventory volatility and unnecessarily high distribution costs. To overcome these challenges, a tailor-made S&OP process is necessary.

Following a holistic analysis performed by ORTEC experts, this large fabric manufacturer found that the production choices they were making resulted in plant downtime. It turned out that some types of fiber were more likely to cause shutdowns. With a tailor-made and global S&OP process, it would have been easier to address a strategic question: “do we want to keep producing these types of fiber or should we focus on others?” Their operations team would have had more insight into what happens throughout the value chain, so they would also know which customers are strategically important from a management stance. Getting departments to talk each other and contribute to the decision-making process is a key benefit of S&OP. Our approach brings marketing, sales, and operations teams together within complex organizations, resulting in successfully implemented S&OP processes and solutions. It’s crucial to note that the most important aspect of S&OP is the process and change management, not the tooling. Tooling is there to support organizations in decision making once the process improvements are clearly identified. Ultimately, your business goals should be leading in order to bring everyone around shared goals.

AIMMS and ORTEC are partners in business for more than 20 years. AIMMS delivers tools for modeling and optimization and ORTEC creates specific applications that embed industry expertise.

In using AIMMS, ORTEC can offer rapid prototyping and transform it quickly into attractive applications for end-users. This allows for immediate use, which means steady progress on maturing your S&OP journey.

Trusted by