3 Ways to Make your Operational Execution More Robust with S&OE

2020 was full of surprises. Many companies struggled to link longer term plans with unexpected short term supply and demand issues. With increasing disruptions and uncertainty, teams need a way to continuously monitor and balance demand and supply in order to fine-tune operations. We put together a survey with our partners at Districon to better understand these challenges and offer ideas for improvement. Our recent webinar offered a glimpse of our findings and shared 3 specific areas teams can work on to keep their supply chain out of firefighting mode. Read on to get a summary or watch the recording.

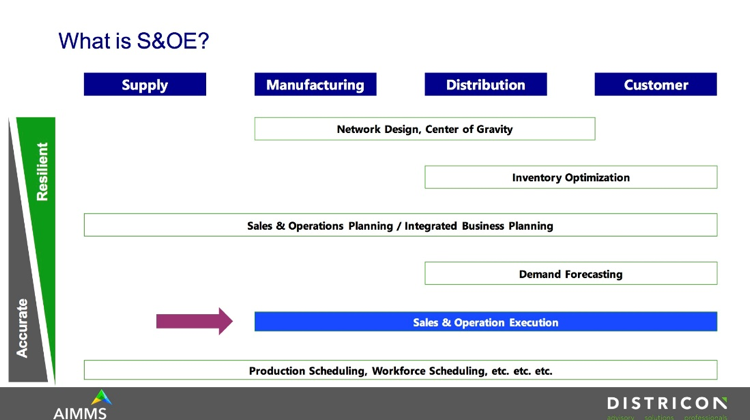

What exactly is Sales and Operations Execution (S&OE)?

If you look at the continuum of your supply chain processes, all the way from supply to customer, S&OE falls somewhere between production and workforce scheduling and demand forecasting. It resides in the realm of Accurate Planning and picks up where S&OP leaves off. While the scope of S&OP might be monthly or quarterly, S&OE’s can be weekly or even daily.

S&OE is all about having the analytics at hand to react in the most accurate way when the unexpected occurs, so you can run your operations on a daily basis. It provides an early warning system that helps business stakeholders sense and optimize their responses. Our research shows that many companies have already embraced S&OE as part of their processes.

How much do our respondents know about S&OE and how satisfied are they?

Industries that deal with lots of daily fluctuations were among the most heavily represented in our survey. Namely, manufacturing, food, and healthcare. Among respondents, 76% said they were familiar with S&OE. However, only 9% are very satisfied with their S&OE solution.

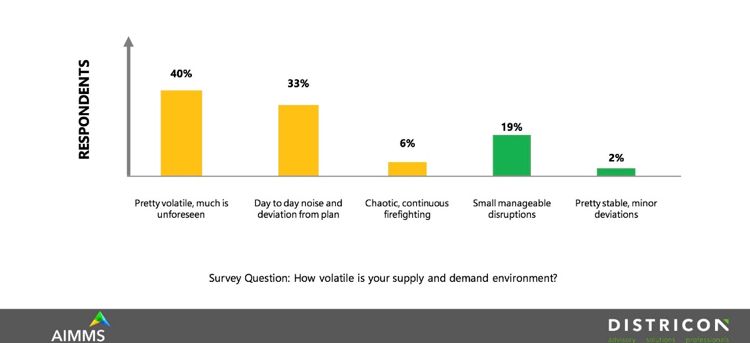

The survey shows that volatility may have something to do with this staggering disparity. Nearly 80% of respondents experience considerable volatility in their supply chain, ranging from many unforeseen changes to continuous firefighting. Only 2% said they see minor deviations.

Nearly 80% of respondents experience considerable volatility in their supply chain, ranging from many unforeseen changes to continuous firefighting.” – Tweet this

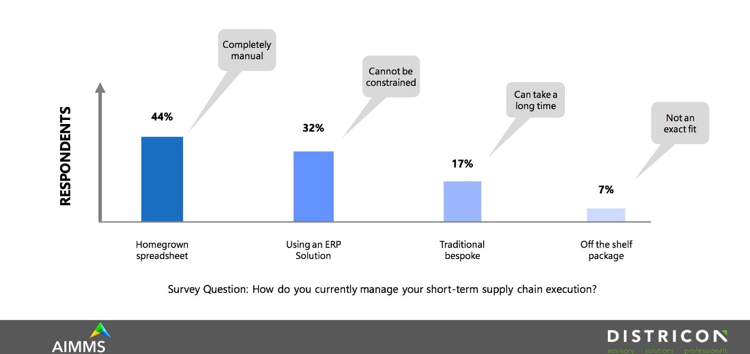

Another reason for dissatisfaction might be the tools used. Over 75% of respondents are using homegrown spreadsheets, which are highly manual, or their ERP, which cannot completely account for complex constraints. Only 7% of respondents use an off-the-shelf package. This makes sense given that S&OE tends to be a very specific process for each company.

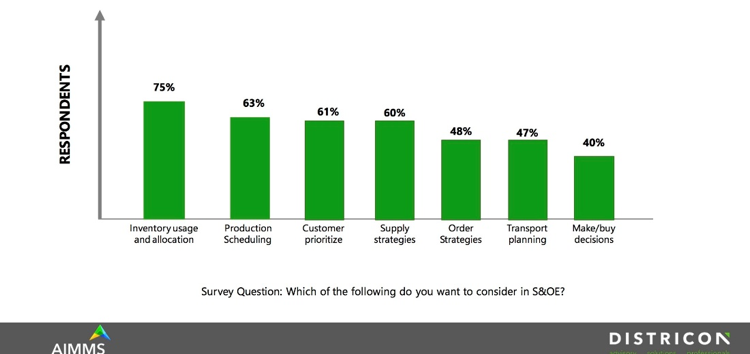

The top 3 bottlenecks companies experience tend to be poor internal alignment between departments, raw material and product availability, and inventory levels and management. There also seem to be many areas teams are considering in their S&OE – ranging from make/buy decisions to production scheduling. With so many things to keep on their radar, it can be difficult to focus on improvements.

Focus on 3 things to improve S&OE capability

As a best practice, we advise teams to focus on 3 things if they want to improve their operational execution. These are:

- End-to-end visibility: integrate with live data and gain visibility into detailed flow data of product availability and customer demand, as well as KPIs. This helps to gain one version of the truth and take collaborative decisions.

- The ability to create scenarios: model one-off events to assess your performance in times of crisis or model alternative ways to resolve problems as they arise.

- Take optimal decisions: leverage optimization models to select the right action when the unexpected occurs.

Focus on 3 things to improve S&OE capability: end-to-end visibility, scenarios and optimal decisions” – Tweet this

How does this work in practice?

Watch the webinar recording to see how a global fashion retailer uses an AIMMS-based application developed by Districon to improve visibility, make better decisions, and speed up reaction times. This retailer was struggling to react quickly to shifts in the market. They wanted to be more flexible in their planning prioritization and make decisions based on data rather than gut feeling. Our solution enabled them to make KPI-based decisions, implement resilient optimization, and smoothen exception management.