Sales & Operations planning has been around for 30 years. It was created initially by Oliver Wight and has become the standard procedure to improve business performance and predictability. Throughout the years, we’ve witnessed waves of interest in S&OP and its evolution IBP, which incorporates financial planning. In the past 2 years, we’ve seen the appeal of S&OP increase a lot more. But companies tend to struggle when it comes to finding the right technology to enable the process. In this blog post, I will delve into 5 issues companies typically experience with their S&OP software.

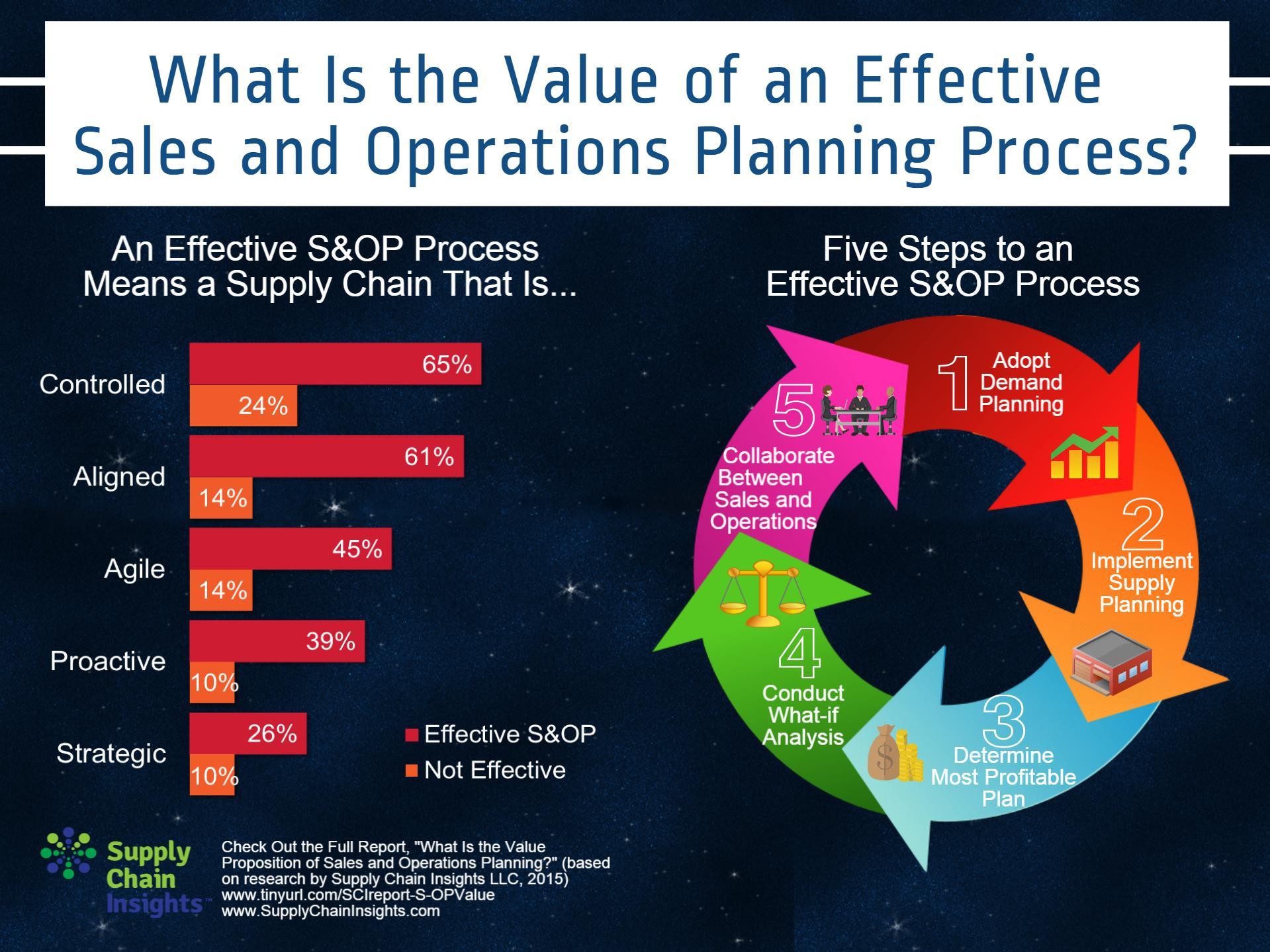

The whole purpose of S&OP is to discuss important questions today to prevent them from causing urgent issues 12 months from now. The business impact of this is profound. As Lora Cecere (Supply Chain Insights) explains, an effective S&OP process can result in a more controlled, aligned, agile, proactive and strategic supply chain. But to implement it effectively, companies first need to understand why S&OP is important for their business. Every company has different business drivers and different requirements. This makes S&OP implementation a difficult process, especially when it comes to finding the right tools.

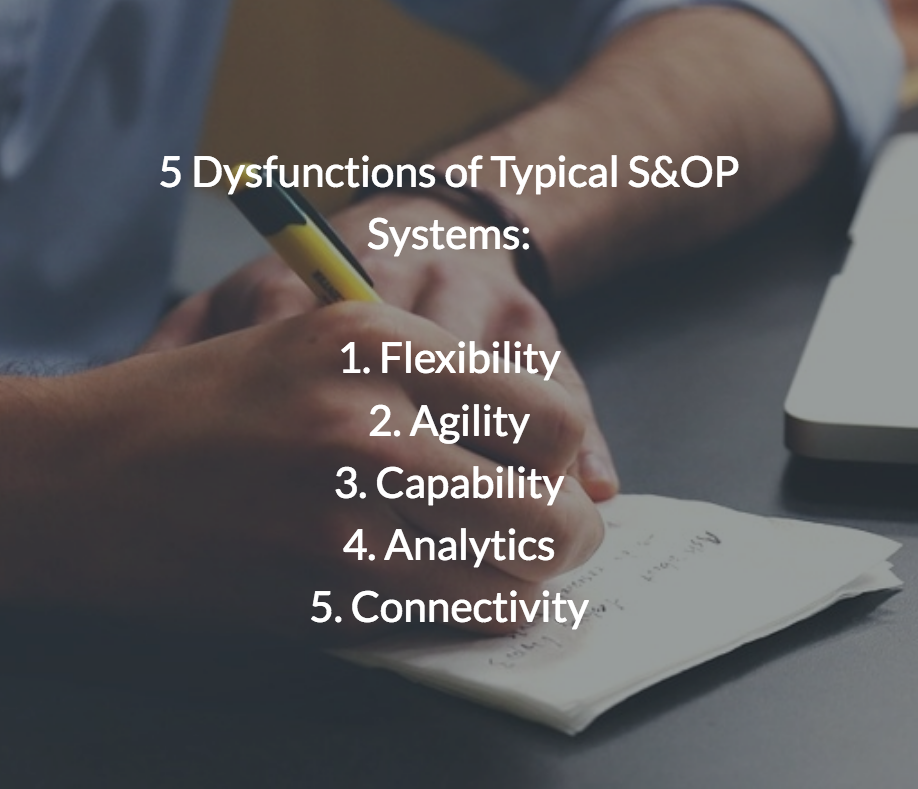

Finding Software to Drive S&OP: 5 Dysfunctions companies typically encounter

Given increased demand for S&OP systems, ERP vendors like SAP and other, more focused, players have jumped on the opportunity to develop best-of-breed software. Typically, companies are looking for tools to tackle demand planning and forecasting. Some are also driving supply chain capability and reconciliation under the umbrella of S&OP.

Many of our clients have developed Apps in AIMMS to support their S&OP process. We did some research to find out why they preferred to use AIMMS over best of breed packages. As a result, we found 5 dysfunctions of existing systems which limit the satisfaction of companies and end-users. These dysfunctions or limitations are:

1.Flexibility: truly capturing the complete (!) essence of the company’s business planning process

2.Agility: allowing companies to capture their complete process in a fast and responsive way

3.Capability: being able to deal with the complexity of all multiple and interdependent trade-offs

4.Analytics: empowering users with transparent prescriptive analytics (optimization) capabilities to generate scenarios and solutions automatically

5.Connectivity: supporting both horizontal (end-to-end) and vertical (multiple time horizons) planning scopes.

Overcoming the 5 dysfunctions

A modeling and analytics environment like AIMMS allows companies to overcome these limitations. Client projects are typically finished within two to four months, demonstrating agility from day one. The extreme diversity of applications shows the flexibility of our software and the ability to connect multiple planning horizons. Let’s take a look at some use cases for S&OP in more detail.

and the ability to connect multiple planning horizons. Let’s take a look at some use cases for S&OP in more detail.

S&OP in High Tech

A high tech company built their S&OP application in AIMMS. Their objective was twofold, besides enabling S&OP, they wanted to streamline their cooperation with distributors. The app they developed helps their distributors identify which products they should purchase and how many. Today, it plays a crucial role in keeping the two-echelon distribution chain of the company lean and agile. With a growing portfolio of products, and the increasing need to minimize slack in the distribution channel, creating the best DPA (Distributor Purchase Advice) became increasingly complex. The company decided to build a smart distribution optimization application that allows for what-if analysis and provides best possible DPAs for the back office. All parties in the channel, including distributors, are happy with the improved insight they needed to steer their operations.

S&OP in the Fashion Industry

A leading sportswear and apparel company works with hundreds of vendors around the globe to produce their products. Their S&OP process is characterized by a strong quarterly season pattern. Therefore, their product portfolio needs to be optimized over multiple quarters taking uncertainty in sales performance into account. AIMMS was chosen as their preferred S&OP technology. Their first applications help them optimize their product portfolio and enable them to allocate production over their entire vendor base, considering important aspects like risk, geography, costs and service.