Where do Integrated Business Planning and Integrated Supply Chain Optimization Meet?

As we discussed it in our previous blog post on Integrated Supply Chain Optimization (ISCO), with ISCO considerations such as demands, materials and capacities are taken into account simultaneously during Master Supply Chain Scheduling (MSCS). Multiple strategic, financial, demand, supply and delivery scenarios are consolidated into one decision process which respects all restrictions, options and priorities. In an effort to explore how the approach works in a real world case, we explored its application at JBS, a world leader in meat processing. The JBS case revealed that ISCO led to a 25% increase in the company’s gross margin. The approach allowed the company’s sales team to identify opportunities from a margin perspective, fully leveraging opportunities that arise from market situations and production capacity.

At first glance, a planning system such as JBS’ could be said to support their Sales and Operations Planning process or even their Integrated Business Planning (IBP) process. But I’ve got my doubts about this assumption. Therefore, I decided to explore these questions on this blog post: is ISCO the same as IBP? And if it isn’t, how do these two methodologies relate to each other?

Defining Integrated Business Planning

Since Oliver Wight are the originators of, and acknowledged industry thought leaders for, Integrated Business Planning, let’s have a look at how they define the process. Integrated Business Planning (IBP) can most simply be described as advanced, or next-generation, sales and operations planning (S&OP). Integrated Business Planning is a ‘common sense’ process, which allows senior executives to plan and manage the entire organization over a rolling 24- to 36-month horizon. IBP aligns all the business functions – sales, marketing, R&D, operations, logistics, finance, HR; even IT – to the strategic and tactical plans, allowing critical resource to be allocated to satisfy customers in the most profitable way. Although IBP works on a long-term forward view of the business, it is managed on a monthly basis through a five-step review process; a series of diarized meetings:

- Product Management Review

- Demand Review

- Supply Review

- Integrated Reconciliation

- Management Business Review

The output of the first three of these reviews Product, Demand and Supply, is an updated holistic plan, which highlights any performance gaps compared to the strategic plan. During the Integrated Reconciliation process the issues are identified and recommendations made, so at the Management Business Review the risks, opportunities and business implications become crystal clear to the senior executive team, allowing them to make informed and effective decisions.

Each of the review meetings is action-oriented and demand rigorous preparation to identify issues and scenarios for consideration in advance of the meeting, such as:

- the constraints and restrictions, e.g. the marketing budget; supply agility; R&D capacity, etc.

- the business objectives, i.e. cost, volume, service, market share and margin

- market risk and opportunities

- the impact of other organizations, e.g. other internal functions, supply chain partners

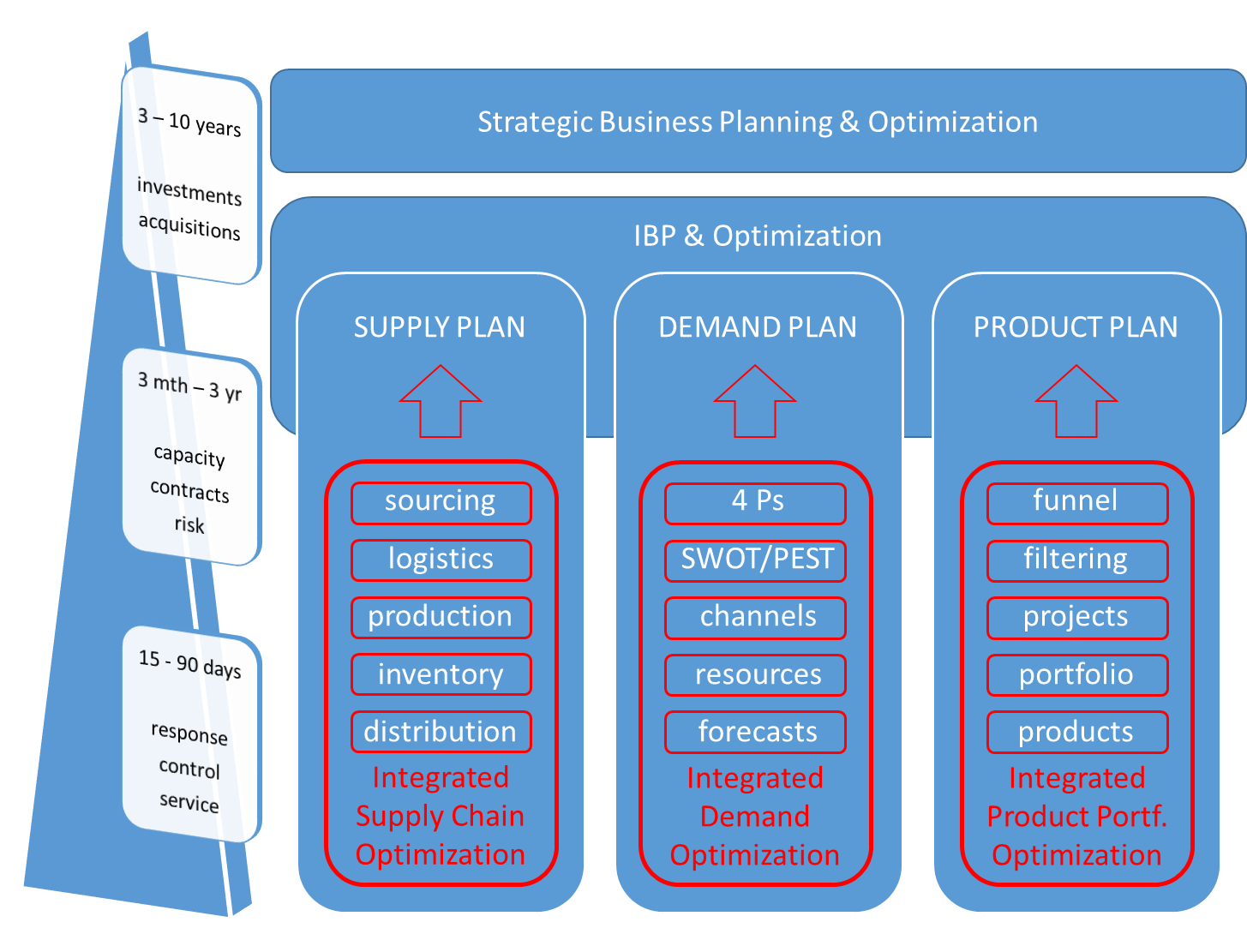

Considering these details beforehand ensures within the meeting decisions can be made, roles and responsibilities assigned, and revised plans agreed, before they are made visible across the entire integrated process. It also allows for contingency plans to be made to ensure the organization is prepared for the future, whatever it holds. Finance has a role to play throughout the entire process, ensuring everyone understands the financial implications of the plans as well as the overall health of the business. This also takes the pain out of the annual budgeting process, since everyone is already working to a realistic bottom-up plan and one set of numbers, updated on a monthly basis. Where do IBP and ISCO Meet? The question that comes to mind now is, how do Integrated Supply Chain Optimization and Integrated Business Planning relate to each other? The picture below provides the answer.  IBP and Optimization puts the supply chain into the perspective of the entire business, following the line of thinking of Oliver Wight. ISCO, the left column of the IBP process, provides the crucial input and insights from the ‘Supply’ side of the company into the business planning process. That’s one key objective. The other key objective is to drive the best possible way to design, plan and control the entire, end-to-end supply chain operation. Many well-known supply chain concepts are to be included in this process to save costs and improve performance at the same time, including:

IBP and Optimization puts the supply chain into the perspective of the entire business, following the line of thinking of Oliver Wight. ISCO, the left column of the IBP process, provides the crucial input and insights from the ‘Supply’ side of the company into the business planning process. That’s one key objective. The other key objective is to drive the best possible way to design, plan and control the entire, end-to-end supply chain operation. Many well-known supply chain concepts are to be included in this process to save costs and improve performance at the same time, including:

- Long range Supply Chain planning, i.e. “Design”, including growth and risk mitigation

- Mid term capacity utilization and service planning, including segmentation, make-or-buy, and multi-echelon inventory planning

- Short term planning, control and response, delivering the best immediate answer to any disruption or deviation of plan, from an end-to-end supply chain perspective

So, to cut it short, while ISCO focuses on optimizing the entire supply chain operation, IBP’s key focus is on optimizing business planning in its entirety. In other words, the supply chain versus the corporate viewpoint. How is IBP adoption faring in the industry? IBP can provide undeniable benefits to an organization, but the business planning process is also highly challenging. Therefore, the vast majority of companies have spent little effort so far in finding the latest and best technology to help them execute their IBP cycle. In addition, all available IBP technologies – other than Excel – focus on facilitating the workflow. They offer little or no help in improving the decision- making process. As Lora Cecere puts it here: “I found that nine out of ten companies were stuck.” You might be tempted to think that this current way of working is satisfactory to most, and that markets don’t demand any progress in business planning. But this couldn’t be farther from the truth. As Gartner describes in their Consumer Products Industry Supply Chain Outlook, 2014: “Revenue growth for the CP industry has been challenging for the past five years. The global economy has made it difficult for even the most successful companies to deliver growth commitments.” Gartner’s annual CP top 10 ranking (see “2013 Gartner Supply Chain Top 25: Consumer Products”), the CP supply chain leaders collectively saw a one point decline in revenue growth year-over-year, from 7.1% to 6.1%. To quote Gartner’s report: “Supply chain leaders are increasingly asked to deliver against business objectives requiring both improved capability and increased efficiency”. Key Recommendations include:

- “Mature S&OP capabilities that support end-to-end integrated business planning and improve management decisions supporting cost and revenue objectives.”

- “The next-generation data analytics solutions will […] become more prescriptive, rather than pattern-based to address what’s happening or has happened. Prescriptive analytics will address and model what can happen under a set of conditions.”

Therefore, we have partnered up with Oliver Wight to jointly explore the benefits that optimization can bring the field of Integrated Business Planning. The first investigations in the field of Demand Plan Optimization have been very promising, as we will explain in upcoming blog posts. Get a roundup of our best supply chain content every month in your inbox! Sign up for our blog digest here.