It’s the time of year to look ahead. I’ve read several interesting articles and blog posts that are trying to pinpoint the developments and trends shaping the supply chain industry this year. They all seem to come from a different angle and while they each make a fair attempt, I haven’t found one that provides a clear view of what 2014 will bring for us. So, I decided to do what I love most: talk with some of our clients and contacts and find out for myself.

Back in the day, I loved to read those AMR reports based on dozens of questions, discussed with hundreds of companies. Their data collection picture looked something like “n=176”. I’m not going to take that approach in this post, otherwise my 2014 outlook for supply chain leaders would only be ready after the summer. My n=9, and as a result my findings are not of scientific value. This doesn’t mean that you will find no value in reading this. Au contraire I’d say, as you will gain insight into the key shifts in focus and improvements that several industry leaders are looking to implement this year. Moreover, you might even see some trends emerging…

At the bottom of this article you can find the complete list of companies with whom I spoke. The findings are grouped into 3 categories, depending on the impact of the changes that they foresee this year.

Strategic shifts in focus from 2013 to 2014

Testament to the growing recognition of the importance of supply chains is the following: three companies mentioned that they made a strategic shift in their supply chain priorities to support a shift in company focus for 2014. One company shifted from a focus on pure growth, to an efficiency focus. That balance might change after some time, but after some years of accelerated growth, it was time to consolidate and focus on the cost base.

Another company made a similar shift from a broad brush strategy to a pure focus on cost control, installing mechanisms to continuously reduce costs. It is quite a change to shift from growth to cost efficiency, your whole mindset needs to change. Ultimately, the shift will impact every decision you make around new facility investment, supplier contract setup, distribution and more.

Sustainability was another priority driving strategic supply chain shifts. One company, in particular, is looking to embrace sustainability in their supply chain strategy for 2014. Their shift will be less dramatic, but will still challenge them to manage this important new aspect with old criteria in their decision making process.

Leap Frog improvement for 2014

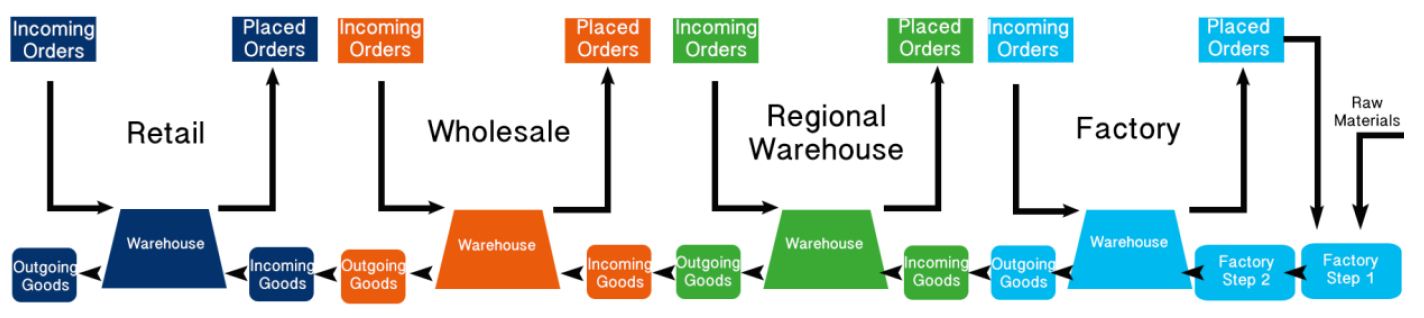

One company has just embarked on a major supply chain transformation process. Their market is in decline, and their leadership realized they had to act fast. What makes it really exciting, is that they aim to round off the transformation this year, even though they only started it three months ago. It involves a radical departure from their current supply chain setup, which was based on a local-for-local sourcing and distribution structure. In one year’s time, they will completely transform their SC by implementing a central control tower. The roles of the control tower will include demand planning, inventory management and replenishment. Once this change is implemented and rolled out across the company, they will shift to a roadmap with evolutionary improvements. Their approach is to synchronize process, people and technology transformation.

How a flexible technology platform can be a key enabler for such a fast, smooth and sustainable transformation, I’ve explored in a previous post. Personally, I find it awesome to see this aspect of our technology ‘in action’ at a real company. I greatly respect the company’s leadership for their willingness and commitment to make this work.

Evolutionary improvements for 2014

Almost all companies had a plan in place for the improvement of their supply chain performance in 2014. For some it was ‘just’ the 2014 plan, for others it was part of a longer growth path in which 2014 would see the foundation to be laid.

Of the five companies that fell in this category, three will focus on gaining more control over their operations. In consulting-speak: raise the supply chain maturity level. For one this means improving the technology to schedule their production activities, sequencing of batches and optimizing the utilization of their assets.

For two others, the objective is higher. They embarked on a three year journey to revamp the complete domain of operations, the integration between demand and supply, and the technology to plan and schedule across their entire supply chain. The interesting difference is that one of them started by selecting the technology and is now in the process of designing the roadmap. The other has found out that they should give at least equally good thought to their people, processes and organization, and is incorporating those aspects in their roadmap as well.

Another company I spoke to has its operations pretty much in shape, but has a major challenge to tackle in its network structure: a mismatch in geographical spread between demand and supply. As a result, the company must focus on studying and redesigning its supply infrastructure to better suit the spread of demand. The realization of that imbalance and its hampering of their growth and profitability is actually quite fresh. The focus on network design therefore implies a major shift from last year’s supply chain focus.

The last company has all its basic processes under control, and will focus on two main areas this year: a shift in the market to different types of products, which will have significant consequences for their supply chain; and a miriad of smaller initiatives in the areas of collaboration and joint developments.

Rounding off

I’m always amazed to see how different each company’s background, drivers, and challenges are. I hope you gained some insights from this post and would like to hear about your challenges as well.

The companies I had the pleasure to speak with in the past few weeks were:

- Unilever, Heinz, Beam Global, Zalando, Remia, RockWool, Bolsius, Papyrus, Disney

I am thankful for their cooperation and feel proud they were willing to share their challenges with me so openly.

Get a roundup of our best supply chain content every month in your inbox! Sign up for our blog digest here.