Creating a Strategy for EU Competitiveness Using Scenarios

The European Union’s economic and industrial landscape is undergoing significant transformation. In response to Draghi’s report on EU competitiveness, the European Commission introduced the EU Competitiveness Compass – a strategic framework designed to improve productivity, resilience, and strategic alignment across industries.

This framework outlines the priorities that will likely shape EU policy in the next decade.

Given the evolving landscape of global supply chains, scenario planning is becoming essential for EU-based companies looking to stay competitive and resilient. Companies must juggle multiple objectives, such as efficiency, cost reduction, sustainability, and resilience, while also preparing for the uncertainties that lie ahead.

This article explores how companies can use scenario planning to adapt to and leverage the opportunities presented by strategic frameworks such as the EU Competitiveness Compass.

The Role of Scenario Planning in Supply Chain Strategy

In today’s rapidly changing business environment, the importance of scenario planning in supply chain strategy cannot be overstated. Recent disruptions, such as global geopolitical tensions, labor strikes at key ports, extreme weather events, shifting trade policies, and the complexities of reshoring strategies, underscore the need for scenario planning.

As companies face increasing uncertainty due to economic fluctuations, regulatory changes, and environmental challenges, scenario planning has become a useful tool for navigating these complexities.

Scenario planning can support the following objectives, which align with the EU Competitiveness Compass goals:

- Anticipating Disruptions and Mitigating Risks: Companies can prepare for possible future events by creating contingency plans that allow them to respond in almost real-time.

- Aligning Supply Chain Operations with Corporate Strategy: Scenario planning can help to ensure supply chain decisions support broader business objectives.

- Improving Operational Efficiency: A well-prepared supply chain is better equipped to optimize costs and improve productivity.

- Building Resilience Against Uncertainties: Companies can establish robust supply chain footprints that can withstand and respond to economic, political, and environmental uncertainties.

Incorporating these benefits into a scenario planning framework allows companies to not only navigate existing challenges but also tackle emerging opportunities and challenges within an evolving business landscape.

Implementing Scenario Planning in Your Supply Chain

To translate policy-driven changes into actionable strategies, companies can follow a structured scenario planning process:

- Identify Key Drivers and Uncertainties: Determine the major external factors affecting your supply chain, such as energy policy changes, trade regulations, and technological advancements.

- Develop Plausible Future Scenarios: Construct different narratives based on how these factors may evolve, ensuring a comprehensive view of possible outcomes.

- Assess the Impact of Each Scenario: Analyze how supply chain operations, costs, and efficiencies would be affected under different circumstances.

- Create Flexible, Adaptive Strategies: Develop contingency plans that allow businesses to pivot based on the scenario that unfolds.

- Regularly Review and Update Scenarios: As new data emerges and policies evolve, continuously refine and adjust strategies to maintain alignment with the business environment.

In this blog post, we focus on stages 1 and 2, as a common challenge in strategic scenario planning is deciding how to develop future scenarios that can be used to aid strategic decision-making.

Policy to Scenario: Translating the EU Competitiveness Compass into Strategic Supply Chain Scenarios

In this section, we have outlined how companies could implement scenario planning, focusing on the first two steps: identifying key drivers and developing plausible scenarios in the context of the EU Competitiveness Compass.

Stage 1: Identifying Key Drivers and Uncertainty

To identify these key drivers and uncertainties, companies can gather and analyze data from various sources. This may include internal data such as historical sales figures and operational metrics, as well as external data from market research reports, industry publications, and economic forecasts.

Tools like predictive analytics (such as demand forecasting) can help companies analyze trends and model potential scenarios based on this data. Additionally, engaging with stakeholders across departments can provide valuable insights into risks and opportunities.

Companies would need to identify and measure KPIs that provide a comprehensive view of the supply chain network; these KPIs could be organized based on the framework given above. By evaluating the key drivers and uncertainties in each of these areas, planners and analysts will have a firm foundation on how to measure the impact of future scenarios.

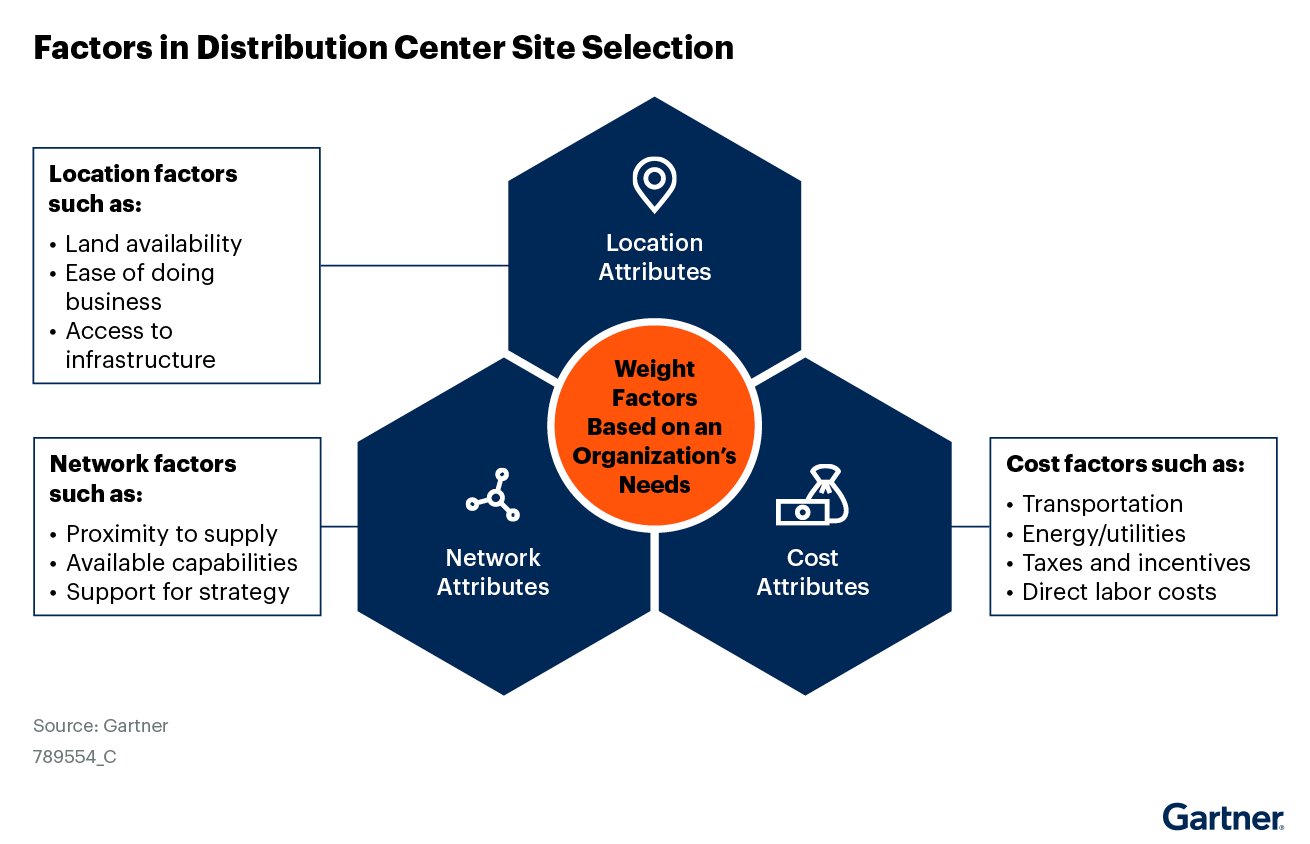

Example: Factors in Distribution Center Location Selection

According to Gartner, “Selecting an optimal location for a new distribution center requires careful consideration of various factors, particularly in the context of evolving EU policies.”

For this use case, they point to “three major attributes influence decision-making:

- Network Attributes: The center’s proximity to suppliers, customers, and transportation hubs must be assessed to ensure efficient operations. As localization trends increase, the site’s ability to integrate into regional supply chains becomes critical.

- Cost Attributes: Land prices, labor costs, and energy expenditures play a decisive role. The Clean Energy Transition could lower long-term operational costs for facilities located in regions with a stable renewable energy supply.

- Location Attributes: Accessibility to major roads, ports, and rail networks affects distribution efficiency. Workforce availability and the regulatory landscape of the selected country also influence site feasibility.”

Stage 2: Developing Plausible Future Scenarios

By developing plausible scenarios, companies can explore how different trends, policies, or disruptions might shape their operating environment. The following examples illustrate how plausible future scenarios can be developed via frameworks such as the EU Competitiveness Compass.

1. Diversification and Resilience

The Clean Industrial Deal may drive companies to reassess their supplier base, encouraging a shift away from dependence on a limited number of sources. Businesses may diversify suppliers, build inventory reserves, and strengthen relationships with stable geopolitical regions.

They could analyze potential supply chain disruptions and assess the risks associated with current supplier dependencies, creating contingency plans for sourcing alternatives and inventory management.

2. Localization and “Made in Europe” Policies

In response to policy shifts prioritizing intra-EU production, procurement strategies may need to adapt in some cases. Companies could face regulatory incentives to source from European manufacturers and integrate more localized supply chain networks.

Also, companies can study the impact of regulatory changes on supply chain logistics, assessing costs associated with local sourcing versus international procurement and forecasting potential shifts in consumer preferences toward locally produced goods.

3. Sustainable Sourcing and Circular Economy Adoption

Sustainability regulations could push companies to rethink sourcing strategies, focusing on ethical procurement and environmental impact. Companies will need to assess whether prioritizing suppliers that align with circular economy principles is the most effective approach, ensuring materials are sustainably sourced and reused within closed-loop supply chains.

Also, they can explore the implications of sustainability regulations on their supply chains by developing KPIs for sustainable sourcing and measuring these against different sourcing strategies.

4. Clean Energy Transition and Industrial Adaptation

The shift away from fossil fuels calls for investment in cleaner transportation and production technologies. This presents opportunities for companies involved in renewable energy infrastructure, as well as those optimizing logistics to reduce carbon footprints.

Industrial firms may also explore long-term electricity supply contracts to stabilize energy costs and mitigate price volatility. Companies could evaluate the economic and technical feasibility of transitioning to cleaner energy sources, and asses the financial implications of investing in clean technologies versus maintaining existing fossil fuel dependencies.

These scenarios demonstrate how companies can leverage structured frameworks, such as the EU Competitiveness Compass, to anticipate and respond to emerging challenges and opportunities. This approach not only helps improve responsiveness but also enables companies to identify growth opportunities, adapt to policy-driven changes, and build resilience over the long term.

AIMMS SC Navigator as a Tool for Scenario Planning

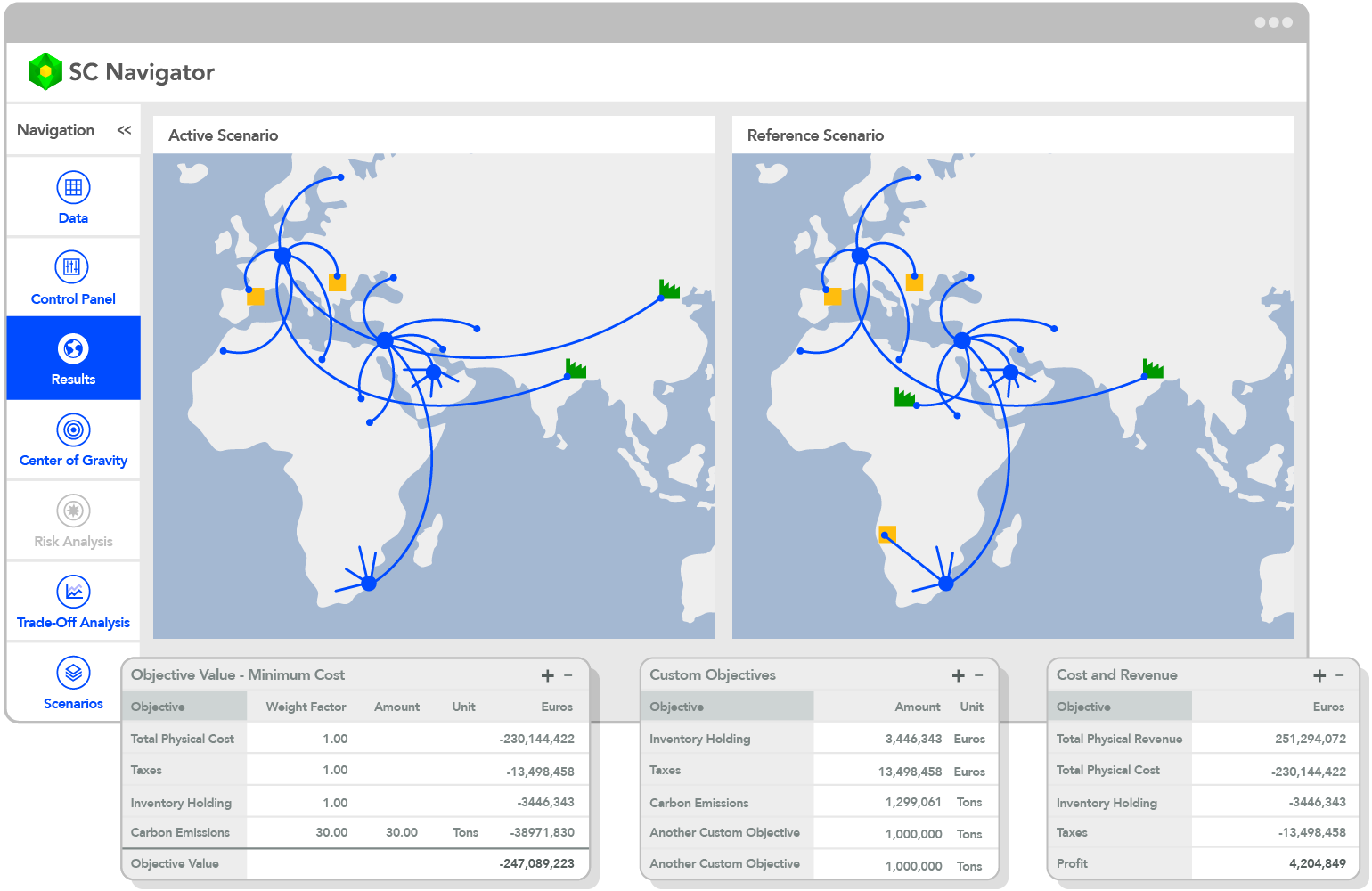

To help facilitate scenario planning, companies can turn to tools that streamline the process. AIMMS SC Navigator is one such solution that offers significant advantages for data-driven scenario modeling.

Unlike some tools, SC Navigator offers the Scenario Navigator feature (see it in action here), enabling businesses to assess the impact of various scenarios by modeling changes in supply chain operations, such as the examples from the EU Competitiveness Compass given above, and visualizing their effects on KPIs that are important to the business.

Additionally, SC Navigator facilitates regular scenario reviews through batch optimization capabilities, allowing companies to analyze scenarios over multiple datasets simultaneously and refine strategies as new data emerges. This makes it easier for businesses to explore and refine their strategies in real-time.

By integrating these tools into their planning processes, companies can make data-driven decisions, improve supply chain resilience, and stay aligned with evolving market conditions.

Conclusion

The EU Competitiveness Compass presents both challenges and opportunities for companies operating within the region. As new policies shape the business landscape, scenario planning becomes an essential tool for supply chain leaders to anticipate changes, mitigate risks, and leverage emerging opportunities.

Companies that proactively adapt to these potential futures will be better positioned for long-term success. Continuous monitoring, strategic adjustments, and a commitment to innovation, sustainability, and resilience will be critical in navigating the evolving economic environment. By embracing scenario planning now, companies can not only navigate future challenges, but also seize new growth opportunities as the landscape evolves. The future is unpredictable, but with the right preparation, businesses can thrive in uncertainty.

Ready to find out how to optimize your supply chain network for your company? Talk to our experts today!