How to Elevate your Product Segmentation Strategy with Supply Chain Optimization?

Product segmentation strategy involves dividing a company’s product portfolio into different segments based on factors such as customer demand, production processes, and distribution channels. A key goal of this strategy is to create a more efficient and effective supply chain that can meet the diverse needs of customers while minimizing costs and maximizing profitability. Segmentation helps design targeted supply chain strategies, enhancing cost-efficiency, service, and sustainability for many sectors.

In general, there is a set of common clusters of characteristics used to segment a product offering like demand volume, strategic importance, demand variability, and profitability.

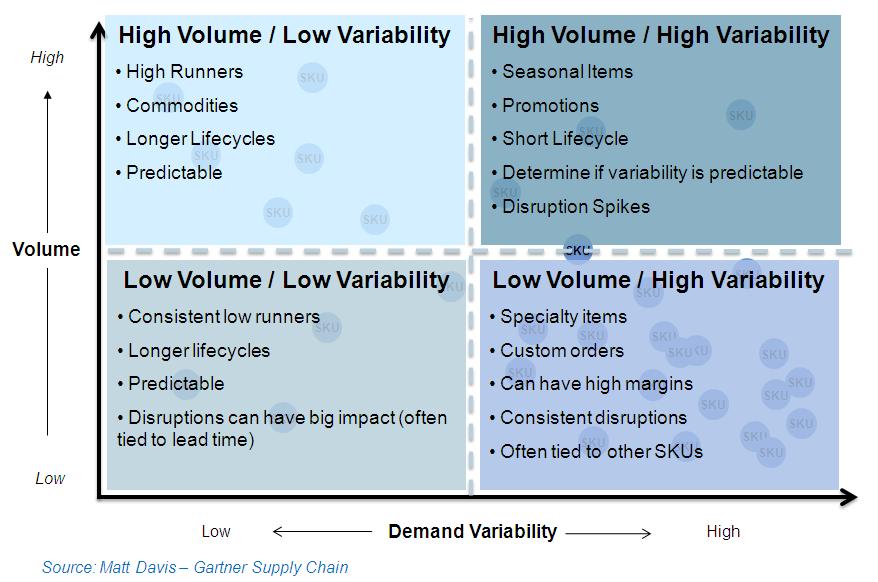

The “one-size-fits-all” does not work anymore for most global providers. The transition to a product segmentation strategy means better personalization, however more complexity. Gartner simplifies this with a 2×2 analysis based on historical data, comparing volume against variability. The outcome is a product performance distribution quadrant, allowing companies to tailor their supply chain strategies accordingly.

Notable examples

Established companies often rely on segmentation strategies when expanding internationally. However, the success of these strategies is not guaranteed, as evidenced by Starbucks’ 2008 Australian expansion. Despite launching 84 stores, inadequate market segmentation and positioning led to poor sales, ultimately forcing the closure of 60 stores and resulting in $143 million in losses at Starbucks.

Coca-Cola and Pepsi use product segmentation in a specific way. The company is offering a Mexican version of its product in smaller US convenience stores. This version is made with real sugar instead of high fructose corn syrup, catering to the preferences of the Mexican market. Similarly, Pepsi provides a real sugar variant of its cola in the US, alongside the high fructose corn syrup version. Both beverage companies also offer a variety of small modifications to their original colas like diet, caffeine-free versions, and versions of extra flavors added.

Areas where product segmentation impacts your supply chain

A global brand’s product segmentation strategy has significant implications for its supply chain. Key areas where this strategy impacts the supply chain include:

Demand forecasting: Product segmentation strategies can influence demand patterns, making it essential for companies to accurately predict demand for different segments. This touches your inventory management, production scheduling, and capacity planning capabilities.

Sourcing and procurement: Different product segments may require different suppliers, raw materials, or components. It can lead to changes in sourcing strategies, supplier relationships, and procurement practices to cater to the specific needs of each segment.

Manufacturing and production: Product segmentation may need different manufacturing processes, equipment, or production sites to accommodate varying product specifications or quality standards. This can impact production efficiency, lead times, and costs.

Distribution and logistics: Different product segments may require specific transportation modes, warehousing facilities, or distribution channels. This can impact the overall logistics network, lead times, and transportation costs.

Product lifecycle management: Different product segments may have varying lifecycles, necessitating tailored strategies for product launch, growth, maturity, and decline stages. This can impact supply chain decisions related to new product introductions, product phase-outs, or end-of-life management.

Risk management: Diversifying product offerings through segmentation can help mitigate risks associated with a single product line. However, it can also introduce new supply chain risks, such as dependence on multiple suppliers or increased exposure to geopolitical or regulatory changes in different markets. Know the top supply chain risks and strategies for managing them.

Key sectors leveraging supply chain optimization to up their segmentation strategy

Complex and fluctuating supply chains demand tailored operating models to effectively address product, customer, and distribution needs. Segmentation helps design targeted supply chain strategies, enhancing cost-efficiency, service, and sustainability for many sectors.

Here are the key sectors that enjoy the great benefits of doing regular supply chain optimization to up their segmentation strategy.

1. Food and Beverage

For food and beverage brands, improving product segmentation strategies involves optimizing the supply chain to better meet customer demands while reducing costs. With a supply chain optimization solution like AIMMS, global brands can:

Streamline supplier relationships: Identify and partner with reliable suppliers to reduce lead times, improve product quality, and manage costs in constantly changing circumstances.

Balance cost and carbon footprint: Model a strategic digital twin of your supply chain network and use it to run multiple trade-off scenarios between cost and sustainability metrics.

2. Retailers

For major retail companies, managing product variety involves balancing the needs of various customer segments and ensuring the right products are available at the right time. Supply chain optimization solutions can help retailers:

Optimize assortment planning: Identify the ideal product mix for each location by analyzing customer preferences, demographic data, and local competition.

Implement store-specific replenishment: Automate replenishment processes to ensure that each store receives the right products at the right time, reducing stockouts and inventory carrying costs.

Enhance warehouse management: Optimize warehouse layout and processes to increase efficiency, reduce labor costs, and improve order accuracy.

3. Oil & Gas

For energy providers like oil and gas companies, managing product variety involves optimizing the supply chain to meet the diverse needs of various stakeholders. Scenario planning technology can assist energy providers in:

Improving transportation and logistics: Utilize advanced analytics to optimize transportation routes and modes, reducing fuel consumption, costs, and carbon emissions.

Strengthening risk management: Identify and mitigate supply chain risks, such as geopolitical disruptions and natural disasters, to ensure the continuity of operations.

4. Electronics

Electronics companies face a unique challenge in managing product variety due to rapidly changing technology and customer preferences. AIMMS helps companies in this sector by:

Accelerating decision-making on your product mix: quickly add or remove products from your offering and evaluate the best way to consolidate and flow your products throughout your network based on their costs, selling price, and profit margins.

Improving demand-supply alignment: Utilize advanced analytics to match production levels with customer demand, reducing excess inventory and lost sales.

Enhancing reverse logistics: Implement efficient processes for repairs, recycling to minimize costs, improve customer satisfaction, and reduce environmental impact.

We can freely conclude that a product offering has a strong influence on how you structure your business supply chain operations. Having the right resources, skills, and technologies to analyze scenario data will help you make the right decisions.’

Learn more about multi-objective scenario planning and how AIMMS enables it.