Global Fashion Retailer Optimizes Sales and Operations Execution with AIMMS

This global fashion retailer produces a variety of consumer products, including shoes, bags and clothing. Production takes place mainly in Asia, but also in other locations. The company has its own stores but relies mostly on other retailers to sell its products, generating an annual revenue of over $500 million. The retailer’s European customer service team asked AIMMS implementation partner Districon to develop a Sales & Operations Execution (S&OE) application that would help them route and schedule shipments to their retail customers, based on supply and demand. This ambitious team was looking to improve product availability and revenue, while lowering CO2 emissions and keeping costs under control.

Problem

The customer service team monitors product inventory and the inbound flow of goods, and matches production orders with sales orders. Customer orders are created and updated based on market insights, changing forecasts, new product introductions and key events, such as the super bowl. The customer service team has to choose between several transport modes to deliver orders (including sea, air or train), and take complex constraints like the prioritization of containers into account. They also manage overflow storage locations.

Their main challenge was poor visibility. They struggled to adapt to changing market conditions because of this lack of visibility and found themselves making decisions based on gut feel or external pressure. They were not able to understand the impact of these decisions on their KPIs.

Solution

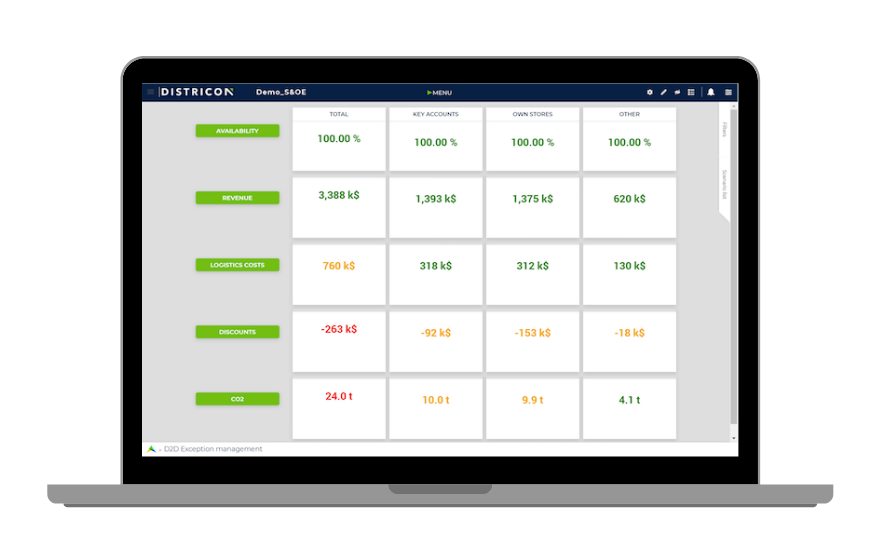

Districon developed an S&OE application using AIMMS that helped the team improve visibility and leverage scenario modeling to assess the impact of unexpected events or disruptions. The app provides clear visibility into their product availability, logistics costs, revenue, discounts, and emissions. About 85% of the data fed into the app comes from the company’s ERP system. Using this data in the S&OE app’s dashboards, they can quickly assess which percentage of products is available or set to be delivered on time. The app also allows them to drill down into details, such as shipment information.

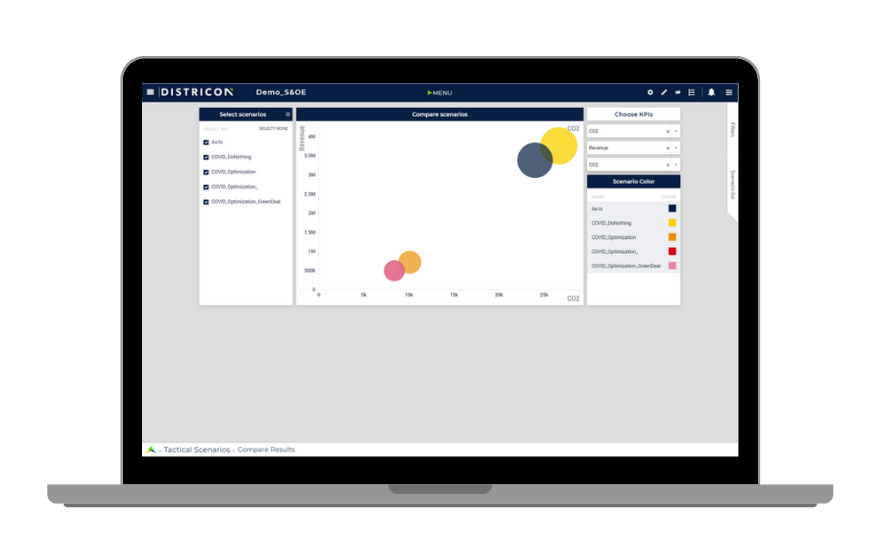

The scenario planning capabilities allow them to test how their KPIs change based on events, like supply disruptions. They can then assess the best available course of action by comparing scenarios and optimize their response manually or using the built-in mathematical optimization model. This model takes multiple constraints into account, such as maximum allowed CO2 emissions and costs.

Results

Thanks to the S&OE application developed by Districon, this retailer is now better positioned to make resilient planning decisions. They can handle exceptions and unforeseen events more easily. Most importantly, their decisions are now backed by data and they can be sure they support their key objectives.

Solution implemented by AIMMS partner:

![]()