Back in 2008, companies tried to release cash from inventory reductions to respond to the first recession’s wave. But this had some unintended consequences. Roughly 80% of them ended up with more inventory levels. Why? Because they adopted a quick fix, an opportunistic approach which forced them into silo planning and severe departmental disconnection. How could they have avoided this? When you look back, the answer is simple: Integrated Business Planning (IBP) and Optimization. My colleague Marcel has written about IBP and Optimization before, and walked you through some of its real business gains. In this post, I will attempt to explain why demand modeling and planning is an imperative in the IBP cycle and what the symbiosis between sales and marketing looks like within the cycle.

Dealing with increasing supply chain complexity

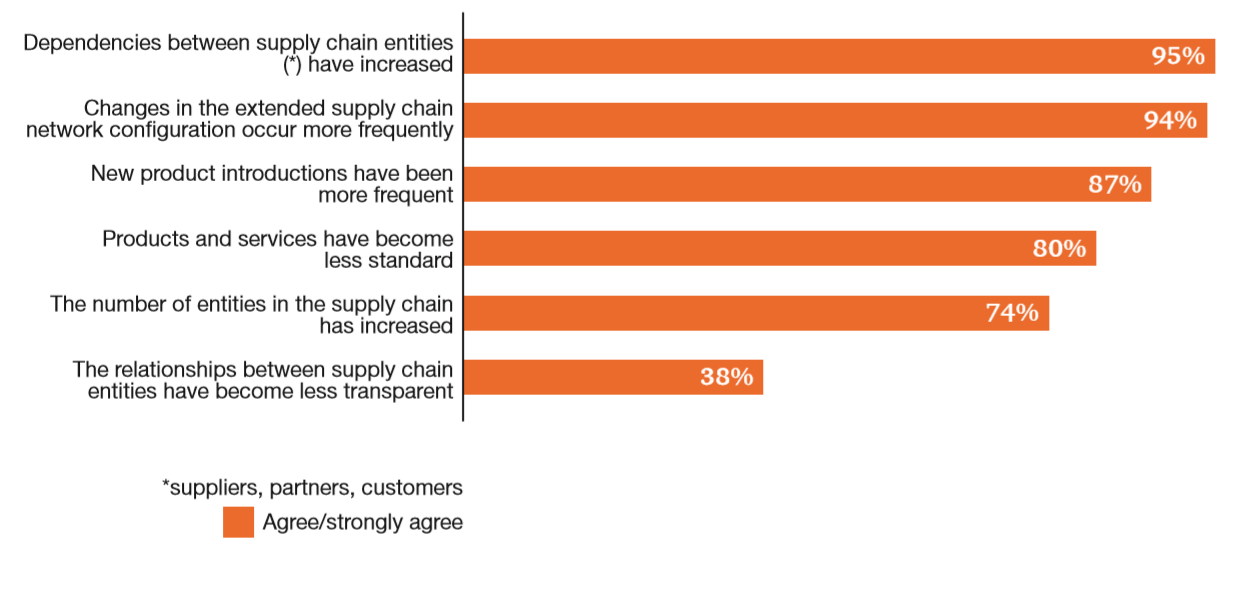

When peeling off the supply chain, everything boils down to a very simple question: What will a customer ask, when, at which quantity and where? The answer is not as trivial though. Companies are trapped between the gears of the supply chain engine, suffering from shrinking margins, diminishing revenues, exponentially growing costs, exhausted inventories, dubious growth and fluctuating service levels.  It is important to realize that customer and demand signals are pushing this engine to roll forward. Therefore, organizations should be able to grasp the perks of understanding demand dynamics and then connect these with other complex supply chain dots, like R&D, production and suppliers. For instance, a recent study by PwC revealed that during the past 3 years supply chain complexity has increased, driven mainly by heavier dependencies between supply chain entities, increasing network changes & disruptions and more frequent new product introductions.

It is important to realize that customer and demand signals are pushing this engine to roll forward. Therefore, organizations should be able to grasp the perks of understanding demand dynamics and then connect these with other complex supply chain dots, like R&D, production and suppliers. For instance, a recent study by PwC revealed that during the past 3 years supply chain complexity has increased, driven mainly by heavier dependencies between supply chain entities, increasing network changes & disruptions and more frequent new product introductions.

By reducing the unexpected variations in your customer demand, you take out some sources of complexity and enable your supply chain to deliver a higher performance. The million dollar question is then how to get better control over client demand.

Why just forecast demand when you can also influence it?

For starters, let’s straighten out the fundamental difference between demand forecasting and demand planning. A forecast is a company’s subjective view on what a market might demand, whereas planning is the organization’s capability to influence and shape demand, respond to customer needs and execute without disrupting the rest of the value chain. In order to start creating more realistic, relevant and objective plans, respecting at the same time the organization’s strategic business objectives and customers’ needs, the “Voice of the Customer” should be recorded and cascaded within the organization. Then, coupled with the history, actuals and forecasting methods, demand signals can be modeled as they are. With this approach, demand plans over the mid-term future could be more pragmatic and demand management and marketing teams can be in control of the plan, not the other way round. Market intelligence and customer analytics should be flowing seamlessly within an organization, allowing all business operations to take advantage of them – from product management and innovation to demand shaping, planning and execution. For example, how can you create a condensed demand plan without bringing in and respecting new product introduction plans and the marketing events that accompany their launch? What if you could shape the demand plan based on the market share you want to achieve? Can you drive your sales and marketing activities in order to increase revenue? If so, how can you be sure that you are doing the right things at the right time?

Taking advantage of Marketing Mix and other determinants to lift your demand plan to the next level

Elaborating on demand shaping and modeling, organizations should be capable to better manage their own inventory pipeline by stimulating demand and increasing the price elasticity of demand. This intentional influence, which subsequently affects revenues, margins and customer segments, should be optimized through advanced customer analytics that estimate customers’ propensity to purchase alternate products. Ultimately, your sales force can guide customers to “next-best” product options through a series of optimized marketing mix (the so called 4Ps Product, Price, Place, Promotion) activities like new product launches, revenue management, assortment, merchandising, placement, sales incentives and marketing programs, price management, trade promotion management and more.

Taking this a step further, a consolidated demand plan should also be able to include a set of financial and sociopolitical factors like disposable income, market size and growth, inflation, market penetration, competitors’ activity, and unplanned events such as:

- Raw material price fluctuation

- Currency fluctuationMarket changes

- Energy prices volatility

- Environmental catastrophes

- Supplier/partner bankruptcy

- Rising labor costs

- Geopolitical instability

But how easily can such a plan be created and what is its business impact?

The “art of modeling”

A good forecast makes you only as good as your competition is. The ability to grasp and model the world as it is and your business truth as you know it, is what can make you a winning player. Advanced optimization technologies can help you quantify most of these “soft” factors mentioned in the previous paragraph, parameterize them and support you in investigating their potential impact on your operations (by simulating different scenarios). These IT enablers can help you go the extra mile by advising the best actions you can take to mitigate adverse effects from a variety of factors. Wood Mackenzie, for instance, has evaluated the impact of the Ukrainian crisis on Europe’s gas flow using AIMMS modeling technology in order to provide key pricing and market insights to their customers. Can you imagine what the impact of a solution that aggregates your history, your strategic objectives and an optimized marketing mix could be? Can you envisage a supply chain with reduced costs and superior customer satisfaction? Are you interested in a demand planning process that is able to align top-line revenue targets with bottom-line profits? Let us know in the comments! Get a roundup of our best supply chain content every month in your inbox! Sign up for our blog digest here.