Introducing Advanced Constraints in AIMMS SC Navigator

AIMMS is always looking to add more flexibility and power without making things more difficult for the users, so I’m very excited with the latest news – SC Navigator now supports Count and Ratio Constraints.

Why is this good news? Let me tell you what you can do with them.

Count Constraints

What are Count Constraints?

Count constraints let you constrain the number of some supply chain elements chosen by the model – whether it’s warehouses, suppliers, sources, or destinations.

Why are Count Constraints useful?

This helps you model a variety of business rules that make your business easier to administer, or your customers happier.

1. Counting Sources

- If your customers are unwilling to accept the burden of handling multiple deliveries, you can insist on only one source per customer.

- If they are a little more flexible, perhaps they’ll accept two for different product groups – e.g. one for frozen goods and one for ambient goods – a maximum number of sources per product group are also supported.

- You can apply those constraints to a group or region of customers if you want to specify that all customers in a region or market must use the same warehouse(s). For example, this could help keep the same-language products together.

2. Counting Destinations

- If warehouses have capacity constraints that prevent them from serving large numbers of destinations (e.g. if dock doors limit the destinations you can serve, or if picking orders for many different customers is a problem) then you can enforce a maximum number of destinations.

- If you don’t want to open a warehouse unless it serves at least some critical number of customers, you can do that too.

3. Counting Locations

- Suppose you want to choose a small number of warehouses for a particular role but aren’t sure which ones, you can put count constraints on a group of warehouses. For example, this could be choosing a number of central warehouses and local warehouses out of a large group of candidates. Or it could be choosing one warehouse to hold all your dangerous goods, so you don’t have to install protections everywhere.

- You can also apply count constraints to production resources. If you want to ensure one production site in each region, you can use count constraints for that. Or if you want to ensure more than one production line is available for critical product groups, you can apply count constraints at a production line level too.

Ratio Constraints

What are Ratio Constraints?

Normal capacity constraints allow you to constrain the amount of product stocked or flowing. You can measure it in any unit you like, but you need to pick a number that will apply no matter what else is happening in the model solution. Ratio constraints allow you to constrain the flow through locations or along lanes as a percentage of other flows, instead of with a fixed number. Then the model automatically adjusts the constraint to its proposed solution.

Why are Ratio Constraints useful?

Ratio constraints can be very useful to build robustness and resilience in the supply chain. Ratio constraints can also be a way of approximating complex business rules without going to a level of detail that you really don’t need in strategic network design.

1. Supplier Ratios

- Want to reduce risk and support the local community? Constrain a minimum proportion of volume to come from local in-country suppliers, rather than overseas suppliers with long lead times and a slow response to disruption.

- New low-cost suppliers are available, but you don’t fully trust them? Look for solutions where no more than 20% of the volume is given to those suppliers.

2. Warehouse Ratios

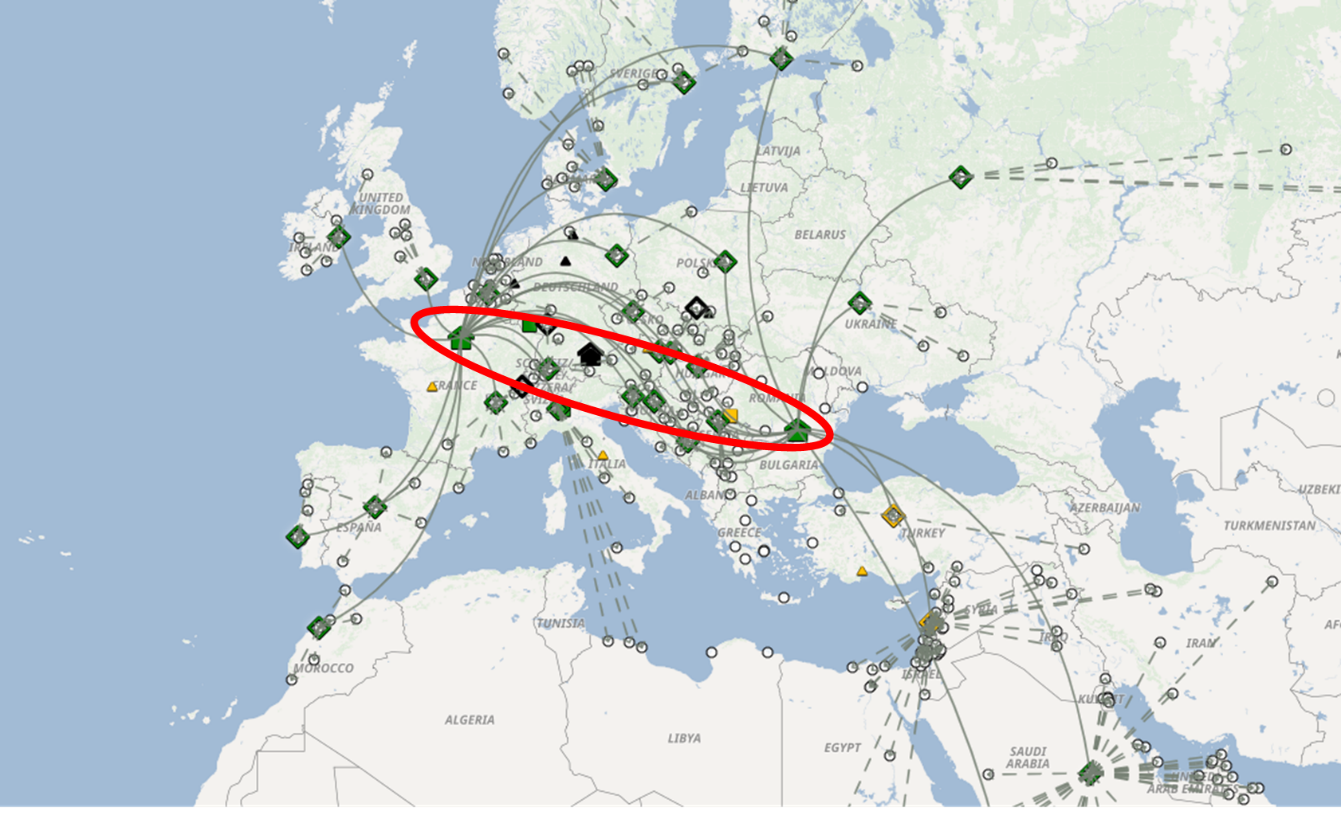

- Want to prevent single points of failure? Prevent this from happening by constraining the proportion of flow that can go through any one warehouse, at each echelon of your network.

3. Production Ratios

- Want to drive an even split of production, so that all resources have a share of spare capacity to ramp up if needed? Define the ratio between production sites, or between individual production lines at a site.

- Want to capture where your product comes from, without having to model at SKU level? Use ratio constraints to say which proportion of a product group comes from each production site, respecting production capabilities without having to make your model big and unwieldy.

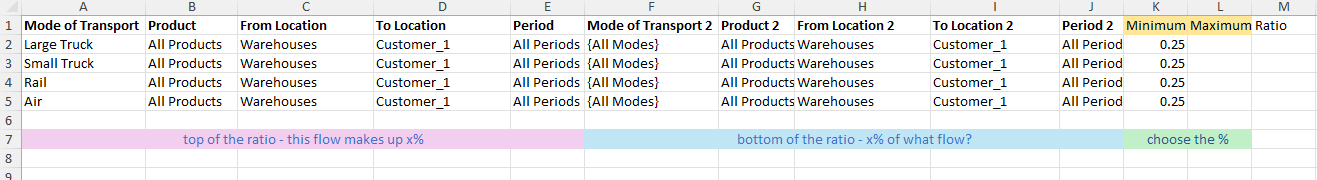

4. Transport Ratios

- Things go wrong in the best of businesses – if you want to capture the costs of some small percentage of your orders needing an expensive expedited delivery you can use transport ratios to force some flow along more expensive modes of transport.

- Project your baseline into the future – historical baselines can be created using the exact numbers that happened in the past. If you want to project that way of working onto future growth (as a first step before looking for new and optimal ways of working) ratios can be an easy way of making transport flows adapt to demand growth.

Ratio and Count constraints are now live and available for Advanced Module users. For more details, check out the documentation.