Key trends in SC continued, as seen at the 2014 European Supply Chain & Logistics Summit in Barcelona

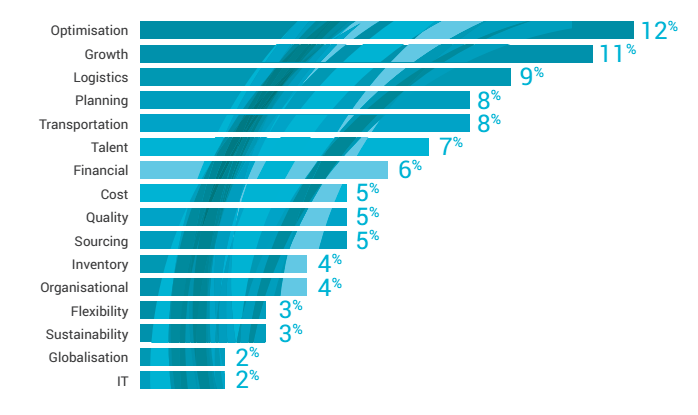

It was great to visit the European Supply Chain and Logistics Summit again this year. On the whole, supply chain leaders seem to be recovering from the blow of the economic downturn, and are looking ahead to seize opportunities. This contrasted with last year’s SC&L Summit, which was all about declining demand in the face of global economic change. The prospects then seemed daunting. But there were also some positive things. For instance, companies started realizing how important it is to leverage SC Analytics, and there was the growing notion that investing in excellent SC people actually does make a difference.Our brief client survey at the beginning of this year also revealed companies were setting more positive ambitions for themselves (let’s grow, instead of let’s stop the decline). This optimism is reflected in the Summit organizers’ survey among delegates as well: Supply Chain Optimization ranked first as their key area of focus. SCO is the superlative of all SC Analytics, and thus survey results confirm that many more people have realized the importance of deep insight gained by Analytics and, in particular, Optimization (as illustrated in the graph below).

It was great to visit the European Supply Chain and Logistics Summit again this year. On the whole, supply chain leaders seem to be recovering from the blow of the economic downturn, and are looking ahead to seize opportunities. This contrasted with last year’s SC&L Summit, which was all about declining demand in the face of global economic change. The prospects then seemed daunting. But there were also some positive things. For instance, companies started realizing how important it is to leverage SC Analytics, and there was the growing notion that investing in excellent SC people actually does make a difference.Our brief client survey at the beginning of this year also revealed companies were setting more positive ambitions for themselves (let’s grow, instead of let’s stop the decline). This optimism is reflected in the Summit organizers’ survey among delegates as well: Supply Chain Optimization ranked first as their key area of focus. SCO is the superlative of all SC Analytics, and thus survey results confirm that many more people have realized the importance of deep insight gained by Analytics and, in particular, Optimization (as illustrated in the graph below).

Presentation highlights

There were the many positive stories of companies who embarked on a set of SC transformations (popularly called ‘a journey’), and gained already some successes. Other companies were open about the challenges they have and presented a clear plan on how to transform and improve their organization. Highlights for me were:

- Diageo, where Ivanka Jansen openly shared challenges, successes and a clear approach to aimed at continuously improving the “Route to the Customer.” For me, it shows real personal strength and organizational transparency if you are able to openly reflect on areas where your organization still has room for improvement. It makes the whole story so much more realistic. We all have our share of struggles, don’t we?

- Rockwool presented a similarly inspiring talk. The presentation, offered by their head of SC Martin Berg and two other colleagues, was playful, engaging and professional. They presented a hands-on approach to reducing the product portfolio (length of the price list) in a collaborative way. Their approach involved all departments, including sales, and still kept a keen eye on the overall company margin objective. Analytics were a key enabler for clean and open discussions.

- Papyrus’s was also enthralling. SC Exec Bob Woodburn openly shared the company’s challenges (we all use less paper, reducing their revenue by an annual 6%), and how they had to respond fast to stay in the black figures. His journey (that word again) started with a network design study, which stated they should reduce the number of warehouses to about one third of what they have now. However, in order to do that he needed to setup a central forecasting, demand planning, inventory management and replenishment center. Quickly. With 3 different SAP instances in the way. He then asked himself the question: “Why don’t we bring the modeling and optimization capabilities of AIMMS [also used for the network study] down to the level of daily operations?” Papyrus developed a solution in collaboration with our partner Districon within 6 months of having this idea, deploying it in half of the EMEA region in record time. His last 6 months showcased for me an interesting new approach, namely to seamlessly progress from the strategic analytics level to the use of analytics in your daily operations.

- Volvo Powertrain are on a roll, as I also know from previous conversations with Julie Maes, their strongly involving SC leader. Unfortunately, I only picked up the last part of her presentation, but it was sufficient to witness that the audience greatly liked it, and Julie had her approach well founded in analytics.

Conversation highlights

We also has several interesting conversations with senior supply chain leaders. The general trend it that SC leaders are looking for fundamental improvements to their supply chains. They realize that short cuts are not sustainable. Simply swapping one system for another is not seen as a solution anymore, which is great. A key issue of which more and more leaders seem to become aware of, is that you do not know what your needs will be two years from now. Or five years for that matter. Or what domain of your supply chain needs the highest priority. In other words, leaders know the start of their ‘journey’ (last time I use the word in this post, I promise), and their objectives, but they do not know what transformations they will need exactly after the current program is finished. This is a growing realization amongst supply chain leaders, and they are challenged by the classic approach adopted by virtually all SC solution providers. Vendors or solution providers obviously all have great stories about how good their software is. And they are right. They typically built in a wealth of domain expertise into their systems, and designed great solutions around it. Their solutions. And they are based on Their view on steps to take in maturing your supply chain. And they usually are good steps, even excellent. Question is, are they identical to Your steps? Do You feel comfortable to adapt your unique supply chain to their off the shelf solution? Well, truth is, many people still feel comfortable with that. But I also noticed a growing number of SC Leaders that feel they need an alternative. We were happy that we could tell a different story to the leaders we met. A story about “designing your own process”, “master your own technology”, and “tailor-made operations deserve tailor-made technology.” As the concept is quite new and ground breaking, not all leaders immediately embraced it. However, those who have seen the technology in action with Bob Woodburn of Papyrus, were very excited about the value and performance it brought.

Get a roundup of our best supply chain content every month in your inbox! Sign up for our blog digest here.