Long-Range Capacity Planning and Network Design in the Pharma and High-Tech Industries

How do you ensure that your supply chain will have enough capacity a few years from now?

Sounds complex, right? Fortunately, there is technology to help answer this question.

In pharmaceuticals, medical devices, high-tech, and other manufacturing industries, this question is critical and cannot be ignored. These industries operate in highly competitive and rapidly evolving environments, where demand fluctuations, technological advancements, and regulatory requirements present continuous challenges – on top of the usual disruptions that every supply chain company faces.

Efficient capacity planning and robust network design are crucial for maintaining competitiveness and ensuring product availability, with the right service levels and financials.

Understanding Long-Range Capacity Planning

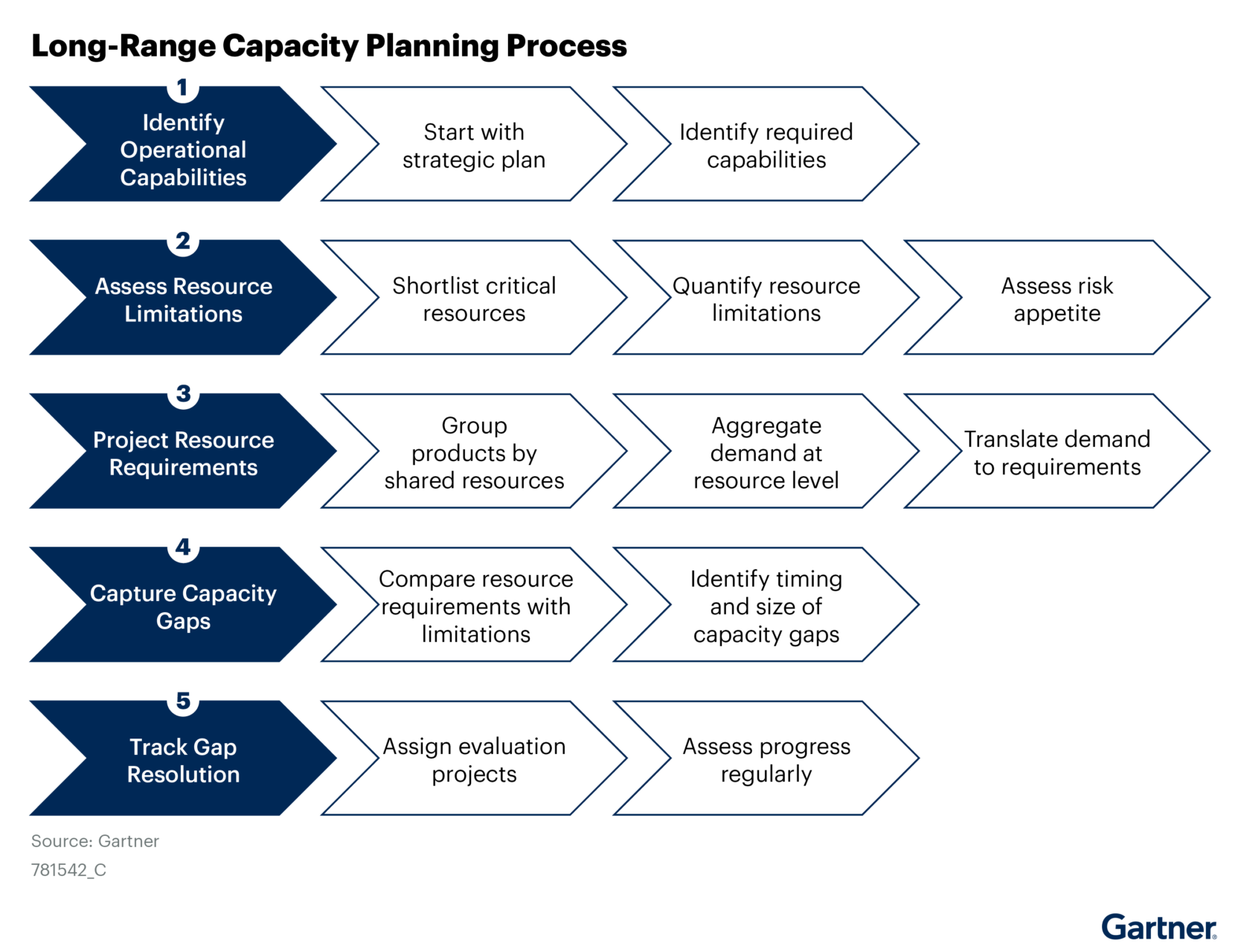

Long-range capacity planning is a strategic process that involves forecasting future demand, and ensuring that the necessary production resources – such as facilities, equipment, and labor are available to meet those needs.

The planning typically spans several years, sometimes more than 10, and incorporates factors such as company strategy, market trends, future risk, technology developments, and anticipated changes in consumer demand.

The output of the process is a forward plan of Capital Expenditures (CapEx) investments required for brownfield and greenfield capacity increases (or decreases), and a timeline of when these investments need to happen.

Key aspects of long-range capacity planning include:

- Long-term demand forecast scenarios: predicting future demand based on historical data, market analysis, and emerging trends.

- Optimal resource allocation: determining the necessary resources (e.g., machinery, human resources, raw materials) required to meet demand.

- Capacity expansion roadmap: planning the acquisition and deployment of the extra production equipment required to expand capacity.

- Risk management: identifying potential risks and developing strategies to mitigate them.

- Sustainability: understanding the impact on ESG targets.

- Financials: balancing the CapEx costs of capacity expansion with the expected benefits.

The Role of Network Design Technology

The complexity and uncertainty involved in future planning require more than just strategic layout and optimization. There are simply too many variables and potential scenarios to consider without the help of decision support tools.

This is where Network Design technology plays a pivotal role in enhancing the efficiency and effectiveness of long-range capacity planning.

AIMMS offers SC Navigator, a supply chain network design solution that stands out by its powerful scenario planning, ease of use, and personal high-care implementation support and onboarding.

In the context of pharmaceuticals and high-tech industries, network design involves the strategic arrangement of production facilities, distribution centers, and modes of transport to optimize the flow of goods and services. Advanced network design tools, like AIMMS SC Navigator, leverage data analytics and optimization algorithms to create robust and flexible supply chain networks, even with a planning horizon of more than 10 years out.

AIMMS supports customers like Philips, Intel, Zoetis, Sanofi, Boston Scientific, ASML, HP, and many more. While each company is unique, they share a common characteristic – the need to ensure sufficient capacity over long-term horizons.

Read how AIMMS helped Intel to optimize its supply chain with Digital Twin.

Benefits of AIMMS SC Navigator, a Network Design Application

- Do more with less: By running different scenarios and assessing various factors (e.g. costs, service levels, carbon emissions), SC Navigator helps in identifying the most efficient allocation of resources. This ensures that production capabilities are aligned with market demands without overburdening the supply chain.

- Scalability and flexibility: SC Navigator can model various growth scenarios, helping companies plan for capacity expansion or contraction. This is particularly crucial in the pharma, medical devices, and high-tech industries, where market dynamics can change rapidly due to new drug discoveries or technological breakthroughs.

- Risk mitigation: SC Navigator allows companies to identify vulnerabilities in their supply chains and develop contingency plans. For example, the tool can reveal the weaknesses of the network and the impact of potential disruptions (e.g. climate change or geopolitical risk), important input to plan for alternative strategies to maintain supply chain continuity.

- Prepare for uncertainty: When planning on a long-range horizon a single plan approach is not sufficient. SC Navigator allows you to run and evaluate multiple scenarios, which is an effective way to plan within the cone of uncertainty, being prepared for disruptions, upsides, downsides, and black swans.

- Financial return: For industries with high research and development investments, cost savings can be redirected to innovation efforts. By using SC Navigator to optimize costs or profit, operational costs can be reduced and questions such as ‘how to best invest?’ or ‘how to balance costs versus capacity?’ are answered.

Application by Industry

Leveraging advanced tools for capacity planning is not limited to one industry – this approach can also benefit the pharmaceutical and high-tech industries by uncovering hidden capacities and optimizing resource allocation.

Pharma

Long-range capacity planning and network design are vital in the pharmaceutical industry to ensure the timely and cost-effective delivery of life-saving drugs.

- Regulatory Compliance: Ensures facilities meet global regulations.

- Supply Chain Resilience: Builds resilient supply chains to handle disruptions.

- Time-to-Market: Streamlines production for faster drug launches.

High-Tech

The high-tech industry thrives on rapid innovation and short product lifecycles, making long-range capacity planning and network design essential.

- Innovation and Scalability: Supports scalable production for new tech.

- Global Complexity: Optimizes global supply chains to reduce costs and lead times.

- Customer Satisfaction: Ensures timely product delivery.

Medical Devices

The medical devices industry, like pharmaceuticals and high-tech, operates in a highly regulated and competitive environment. This industry is characterized by stringent quality standards, rapid technological advancements, and a global supply chain that necessitates precise long-range capacity planning and strategic network design.

Growth and Competitive Advantage

Long-range capacity planning, bolstered by advanced network design technology, is a cornerstone of operational excellence in the pharmaceutical, medical devices, and high-tech industries. By leveraging network design tools like SC Navigator, companies can ensure they are well-equipped to meet future demands, navigate market uncertainties, and achieve cost efficiencies. As these industries continue to evolve, the integration of cutting-edge network design technology will remain vital to sustaining growth, innovation, and competitive advantage.

Do you recognize the need to prepare the network for potential new products on a long-range horizon and want to learn how to be better equipped for growth?