Examples of Supply Chain Adjustments and Process Improvements in Manufacturing

The manufacturing landscape is rapidly evolving, driven by advancements in technology and the necessity for efficient supply chain management. Leading global companies are pioneering innovative practices to enhance manufacturing processes, ensuring agility, sustainability, and cost-efficiency.

This article delves into specific examples and strategies employed by supply chain leaders to improve manufacturing processes from an operations research and supply chain optimization perspective.

Strategic Supply Chain Adjustments

As a supply chain decision-maker for a global manufacturer, adjusting your supply chain strategy is essential to navigate the complexities and uncertainties of the current global environment. For instance, a semiconductor equipment manufacturer from South Korea mitigated risk by engaging primary and backup suppliers within the same region, improving the security of their supply without introducing a new regional supply chain. Additionally, Apple has expanded its production to India in partnership with Foxconn to reduce geo-political risk and improve cost efficiency.

Here are some of the most impactful adjustments you should consider.

Building resilience in your supply chain is essential in today’s unpredictable environment. Creating a cross-functional nerve center can help manage initiative-taking responses to disruptions. This center coordinates efforts across departments, ensuring a unified and agile response to crises. Additionally, regularly simulating supply and demand disruptions can prepare your organization for extreme events, allowing you to order components earlier, diversify logistics routes, and maintain higher inventory levels of critical materials.

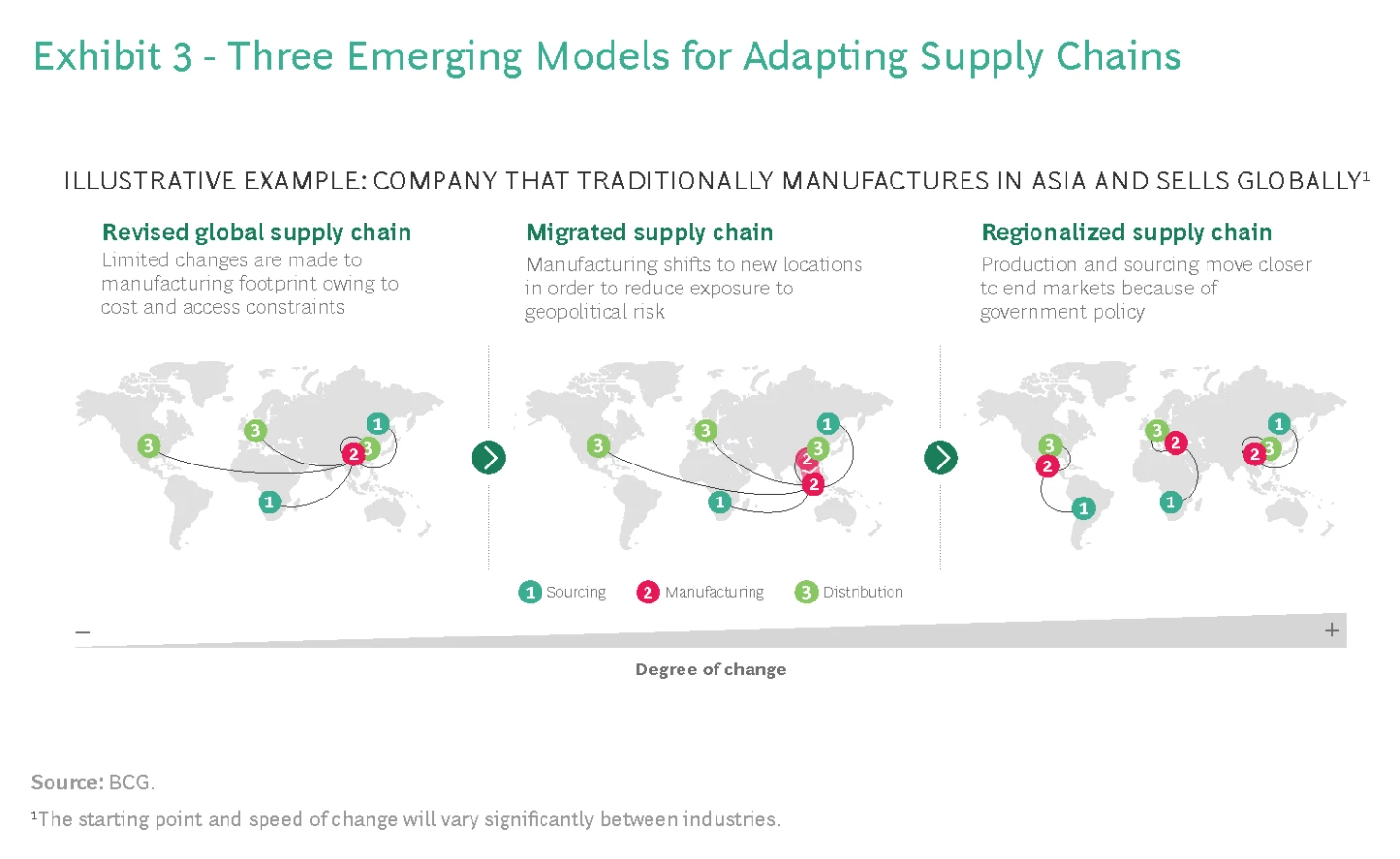

Nearshoring and friendshoring are increasingly significant trends in supply chain planning, driven by a need for resilience and geopolitical stability.

- Nearshoring involves relocating production closer to the company’s primary market. This strategy reduces transportation costs and lead times, enhances flexibility, and helps companies respond faster to market changes. For example, many U.S. companies are moving operations from Asia to Mexico to benefit from geographical proximity and lower transportation costs while maintaining a degree of cost efficiency like that of traditional offshoring locations.

- Friendshoring, however, focuses on sourcing and manufacturing with political and economic allies. This approach mitigates risks associated with geopolitical tensions and trade disruptions. By producing goods in allied countries, companies can ensure a more stable and predictable supply chain environment. This trend is particularly relevant for industries sensitive to trade policies and political stability, such as technology and pharmaceuticals.

Companies can adopt different strategies based on their industry, as illustrated in this BCG report. For example, a motor manufacturer in China might add redundant capacity and qualify multiple suppliers while maintaining low-cost production in China. An apparel or electronics manufacturer might shift some production from China to Vietnam or India to avoid tariffs and trade issues, for example. A biopharma company might regionalize its manufacturing to reduce disruption risks, focusing Asian production on regional markets and setting up plants in North America and Europe for local demand.

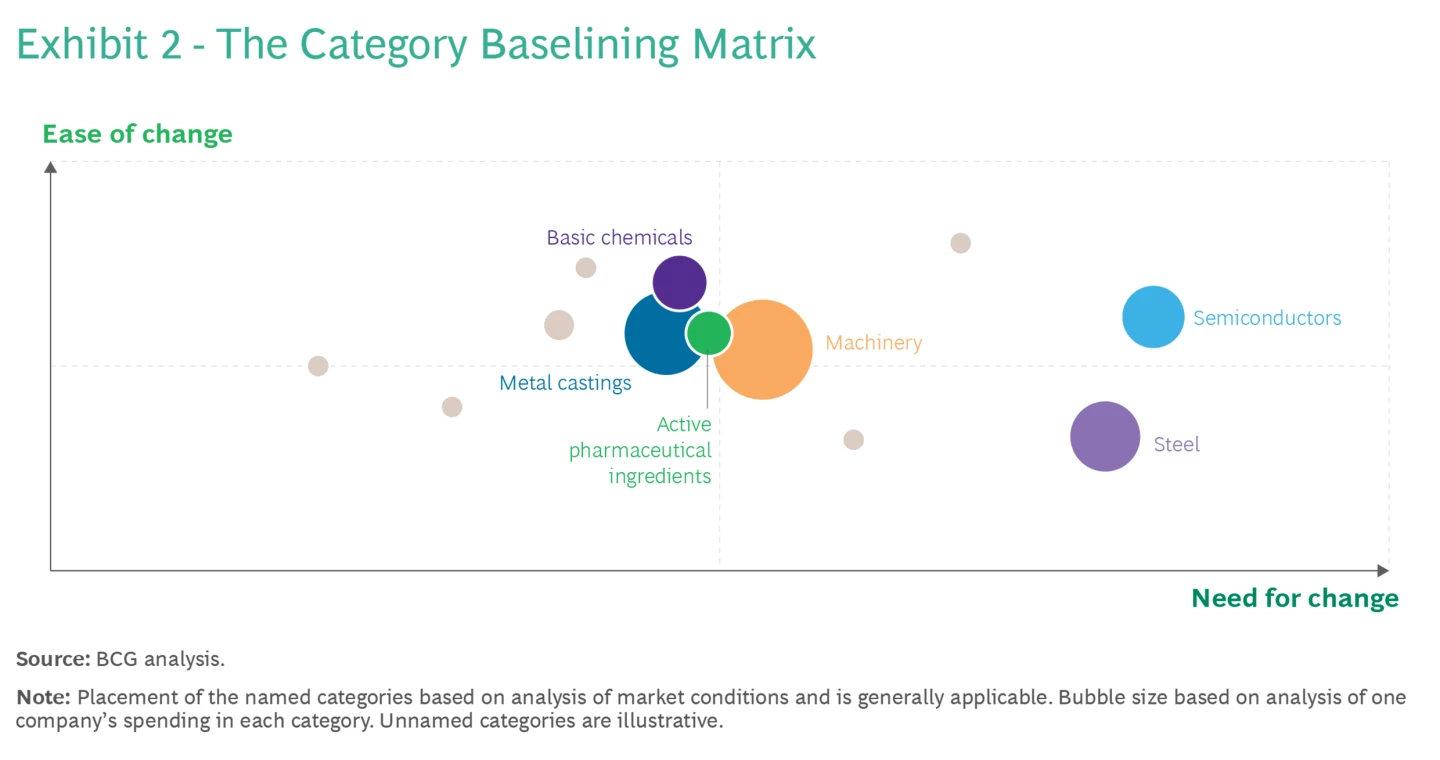

Closely related, sourcing strategies must be evaluated and updated if needed. One common matrix (kudos again to BCG) that is used to evaluate product categories based on the need and ease of change in their sourcing strategy.

- Categories with low urgency for change (left side of the matrix) should still be monitored for potential shifts in market conditions that may require future adjustments.

- Categories in the upper-right quadrant, with a strong need and ease of change, should have their sourcing strategies revised, considering factors like product lifecycle and sourcing costs.

- Categories in the lower-right quadrant, despite needing change, present complexities that require a balanced approach to risk mitigation and operational stability.

Incorporating sustainability and risk management into your strategy is increasingly important. Sustainable practices not only reduce environmental impact but also meet the growing demands from customers and regulators for eco-friendly operations. Developing robust systems for monitoring supply chain risks, including geopolitical, economic, and cybersecurity threats, is also vital. Regular assessments of supplier stability and the implementation of advanced threat detection systems can help safeguard your supply chain from potential disruptions.

Learn more about our Location Risk Analysis functionality and how to optimize for CO2 emissions in SC Navigator.

Continuous Process Improvement and Lean Practices

In the context of continuous improvement and lean practices, several strategic shifts can significantly enhance the efficiency and effectiveness of your supply chain. These shifts focus on creating more value for customers while minimizing waste and fostering a culture of ongoing improvement.

One of the top strategic shifts is adopting a more agile and iterative approach to supply chain optimization.

At AIMMS, we segment the optimization projects into strategic, tactical, and operational planning.

As a general trend, due to increased uncertainty, strategic and traditional multi-year capital expenditure programs are being updated with more flexible, agile development projects and studies that consider various scenarios.

This shift allows for rapid adjustments and improvements, which are crucial in responding to the fast-changing market conditions. For example, adopting a “garage approach” that integrates cognitive diversity from various experts, including technology, design, and enterprise resource planning, can address immediate supply chain issues while aligning with long-term strategic goals.

Another critical shift involves enhancing collaboration and centralization across distinct functions within the supply chain. Creating a cross-functional nerve center helps coordinate responses to disruptions and ensures a unified approach to continuous improvement efforts. This nerve center can manage initiative-taking responses to supply chain issues and coordinate initiatives across various departments, fostering a culture of collaboration and continuous improvement.

See in more detail how Heineken centralized their strategic planning in one of our recent blog posts.

Adopting lean manufacturing principles is also essential. Lean practices such as value stream mapping, kaizen (continuous improvement), and the 5S methodology (Sort, Set in order, Shine, Standardize, Sustain) can help identify and eliminate waste in the supply chain. These practices not only improve efficiency but also enhance product quality and customer satisfaction.

Conclusion

The integration of advanced technologies, strategic supply chain adjustments, continuous improvement methodologies, and sustainability practices are driving significant improvements in manufacturing processes. As global supply chain leaders continue to innovate, these strategies not only enhance operational efficiency but also ensure resilience and sustainability in an increasingly complex global market. By adopting these practices, companies can navigate the challenges of the modern supply chain landscape and achieve long-term success.

If resilience is a key topic of interest, go to the latest Gartner Reprint that we distribute to our readers “Drive Resilience by Taking 3 Actions in Supply Chain Planning“. You’ll find some interesting success stories of global manufacturing brands implementing supply chain resilience strategies.