Overcoming the Toughest Challenges of Electronics Supply Chains with Network Design

In today’s fast-paced world, electronics and components supply chains face some of the toughest challenges, from sourcing raw materials to delivering finished products. But fear not, there is a solution: Network Design Technology.

In this blog post, we’ll explore how network design can help overcome the most daunting supply chain obstacles and ensure success in the electronics industry.

Addressing the challenges and how Network Design technology can help

The electronics and components industry has been growing at an unprecedented rate in recent years. According to a report by Precedence Research, the global consumer electronics market size will grow at a rate of 5.1% per year during the period 2022 to 2030. This growth is driven by increasing demand for smartphones, tablets, laptops, and other consumer electronics, as well as the emergence of new technologies such as artificial intelligence, 5G networks, and the Internet of Things (IoT).

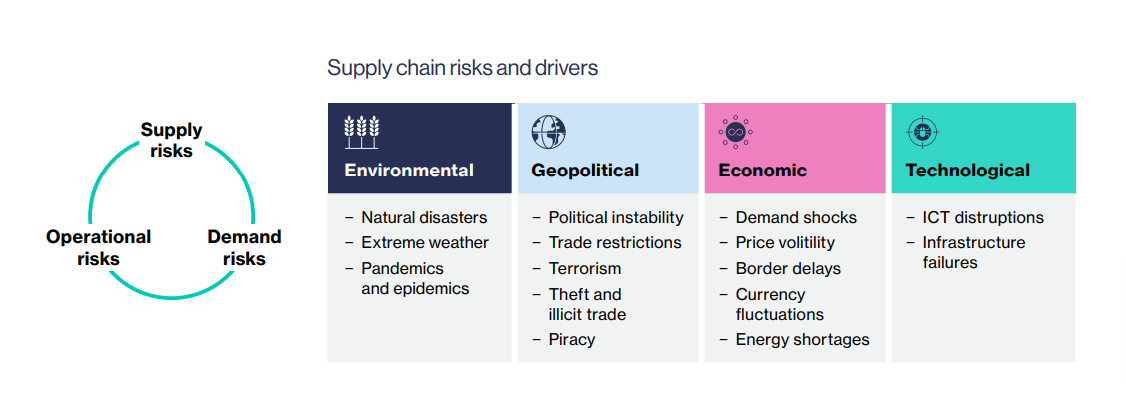

This has led to major challenges in managing supply chains, including global complexity, short product lifecycles, inventory management, how to de-risk the supply chain when disruptions arise, and how to become more sustainable. However, supply chain design technology has emerged as a powerful tool to address these challenges and optimize operations for these businesses using unlimited scenario modeling quickly, easily, and as soon as disruptions arise.

Challenge 1: Complex sourcing journey

One of the biggest challenges the electronics and components industry faces is managing the complexity of global supply chains. Many companies source components and products from multiple locations, which can create logistical challenges and increase the risk of disruptions in the supply chain. Furthermore, the COVID-19 pandemic and geopolitical developments have highlighted the importance of diversifying supply chains to mitigate risks and ensure the continuity of operations.

Supply chain design technology can help electronics and components companies manage these complexities by optimizing supply chain networks and identifying the most efficient sourcing strategies. For example, companies can use scenario planning tools to model different scenarios and evaluate the impact of changes to their supply chain, such as adding new suppliers or shifting production to different locations. By optimizing their supply chain networks, companies can reduce costs, improve efficiency, and mitigate risks.

With AIMMS, you can build multi-echelon network designs while modeling the detailed constraints and costs of your nodes along the way. There is no limit to the number of locations you can model so that you can optimize complex networks and build resilient supply chains.

Challenge 2: Excess stock or empty shelves

Disruptions like Covid-19, the Ukraine/Russia war, and trade wars are currently causing full warehouses but were also causing empty shelves in the past. When storing too much this can tie up significant amounts of capital in inventory. When short in stock this immediately impacts your sales. Furthermore, excess inventory can lead to waste and increased environmental impact.

AIMMS can help you quickly identify the optimal safety stock, in-transit stock, and cycle stock at each of your stocking locations based on any given network scenario. AIMMS Inventory Planning will also help you understand how to rebalance your stock so that your service levels are not compromised. For each of these scenarios, your end-to-end network costs (including shipping) are also being optimized.

Challenge 3: Short product cycles

Electronics and components businesses are managing short product lifecycles. With new products and technologies emerging at a rapid pace, companies must be able to quickly adapt to changes in demand and respond to product discontinuation. This requires a high degree of flexibility and agility in the supply chain, as well as the ability to quickly ramp up or down production as needed.

During a SupplyChainTalk interview, the Global Supply Chain Logistics Manager of the World’s Largest Semiconductor Chip Manufacturer company pointed out that their company does the optimization on a case-by-case basis. ‘There is no one-size-fits-all’, said the spokesperson. At their company, trade-off decision-making depends on the product and on the priorities of the company. This can be ‘cost’ for one product and ‘service level’ for another. The spokesperson emphasized that when the models are there, scenarios are available in 2 days rather than 6-8 weeks when doing this in Excel.

With AIMMS, you can add or remove products from your mix and evaluate the best way to consolidate and flow your products throughout your network based on their costs, selling price, and profit margins. The app also allows you to dynamically create and run multiple demand scenarios to evaluate the impact changing demand will have over time.

Challenge 4: Sudden disruptions destroying your planning

Responding fast or even before major events happen and become major issues has long been a future dream. Recall the ship that blocked the Suez Canal. As a supply chain planner, you immediately wanted to know alternative scenarios with trade-offs to make sure you can still produce and deliver.

Nowadays, companies are investigating AI-powered predictive analytics to identify potential disruptions or supply chain vulnerabilities and de-risk their supply chain by responding before regulations change, climate impact your assets, customer demands evolve, or hidden weaknesses catch you by surprise. This can help companies avoid costly disruptions and maintain the continuity of operations.

AIMMS is a front runner in integrating AI technology in its solutions acting as a digital supply chain assistant who proactively runs scenarios and gives recommendations based on actual developments such as a natural disaster or trade restrictions.

Challenge 5: Becoming more sustainable

Finally, sustainability and environmental impact are increasingly important considerations for electronics and components companies. Consumers are becoming more environmentally conscious and are demanding products that are produced and shipped in an environmentally responsible manner. Furthermore, regulations are becoming stricter, and companies that fail to comply may face reputational damage and legal penalties. Gartner states, “More than half of customers will do business only with companies that practice environmental and social sustainability.”

Supply chain design technology can help companies manage sustainability and environmental impact by identifying opportunities to reduce waste and optimize transportation networks. For example, companies can use scenario modeling tools to evaluate the environmental impact of different transportation strategies or to identify opportunities to reduce waste in their production processes.

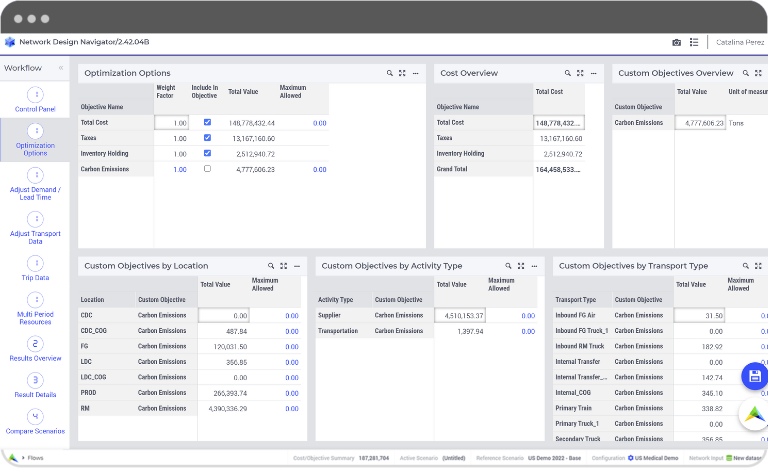

With AIMMS, sustainability metrics can be evaluated, optimized, and their trade-offs with cost and service level can be measured. Through the ‘custom objective’ functionality, you can add carbon emissions, water waste, supplier risk index, or any other sustainability metric and optimize your supply chain for sustainability.

Non-disputable decision-making with Scenario Modeling

So, let’s face it: the electronics and components businesses are dealing with big challenges in managing their supply chain operations. These include global complexity, short product lifecycles, inventory management, managing risk by sudden disruptions, and becoming more sustainable. Fortunately, supply chain design technology can help companies address these challenges by running unlimited scenarios when needed, and by visually sharing the impact of each within the team. Clear considerations regarding cost, service levels, carbon emissions, and risk provide factual input for making decisions that nobody can dispute.

Learn more about how AIMMS helps electronics companies with supply chain optimization.