Management genius Eliyahu Goldratt published his bestselling book Necessary but not Sufficient in 1998. It is still a compelling story about how enterprise resource planning systems lack the ability to create significant value for organizations.

Management genius Eliyahu Goldratt published his bestselling book Necessary but not Sufficient in 1998. It is still a compelling story about how enterprise resource planning systems lack the ability to create significant value for organizations.

Now fifteen years later, Sales & Operations Planning systems seem to be demonstrating a bit of ‘necessary but not sufficient’ themselves. In both cases, organizations assumed that one global planning system would give them the ultimate visibility, agility and significant cost savings.

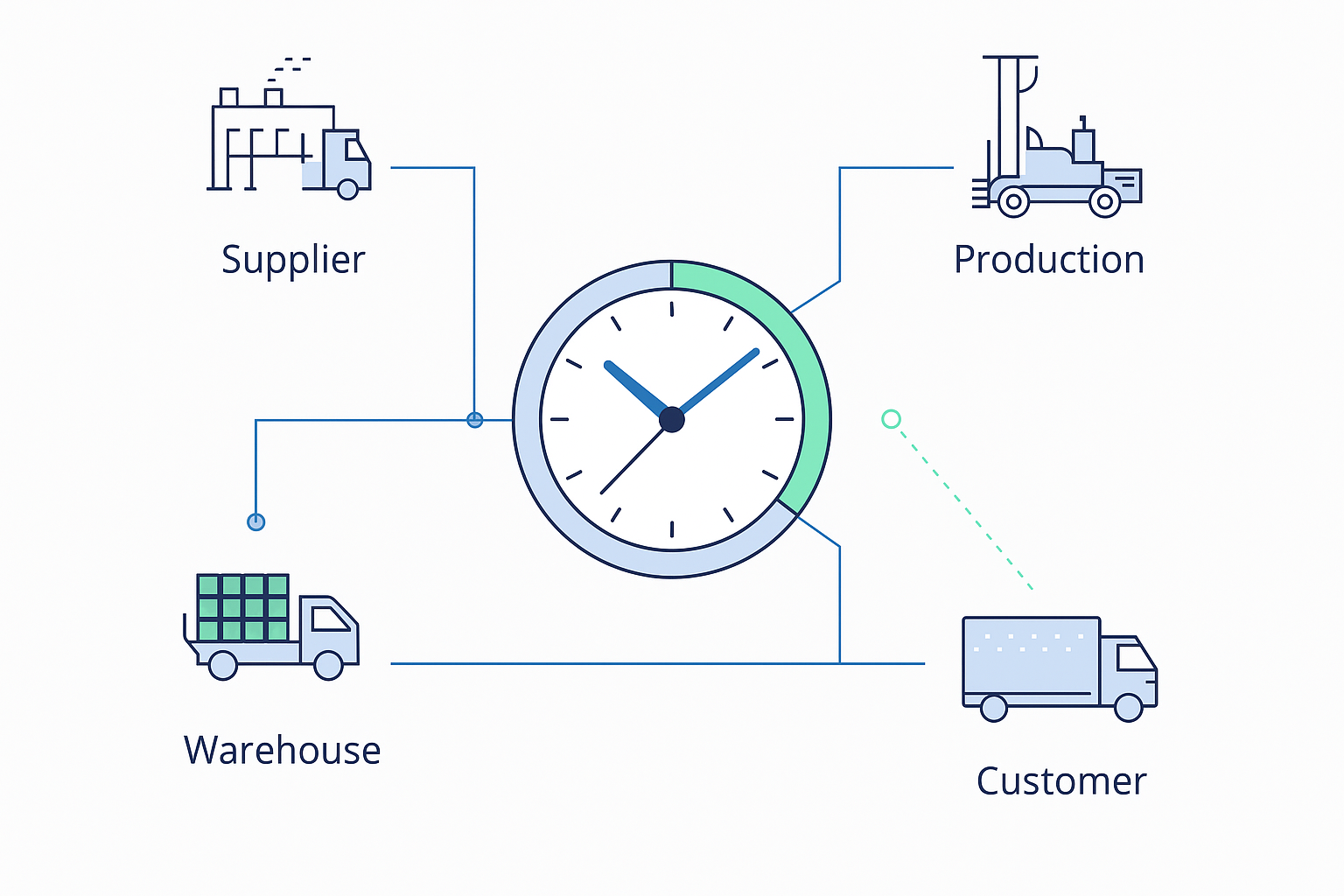

S&OP systems are built to help companies synchronize their demand and supply plans. But, especially in bigger organizations, it is a challenge to align different division plans and goals for many reasons.

The top three reasons why S&OP is ultimately necessary but not sufficient:

- the aligning process is based on a consensus model

- it is limited in supply chain scope

- there is no intelligence inside

Consensus Model

The idea behind S&OP (or IBP) is that all actors involved in the planning process align their plans and goals in such a way that demand is synchronized with supply. The alignment process is based on a consensus model and human interaction, which inherently assumes high risk, uncertainty and positive outlooks. Unless we agree that most sales forecasts are accurate? What would it cost your organization to have 2% hidden stock?

Limited Supply Chain Scope

S&OP synchronizes plans among different actors but this does not, for instance, include where to optimally source materials and components, what products should be made where, how the supply chain should optimally support new product introductions, insource versus outsource decisions, and other issues. How much would a 15% savings on your global transport bill mean if you can source, produce and deliver from better locations?

What about emissions and sustainability advances?

No Intelligence Inside

Optimization is too often left out the S&OP process. How do you know if the demand consensus plans are feasible and that supply can support it? How do you know if there are no better alternative plans? Should you plan for lowest costs possible or for highest margin possible? How do you replan in cases of supply chain disturbances or inaccurate plans? If your S&OP process does not use optimization to calculate best plans and explore alternative options, you may not be significantly adding value to your organization.

Necessary AND Sufficient

Advanced optimization technology can leverage your S&OP process by creating significant cost savings and/or profit maximization based on consolidated S&OP data.

Optimization will help in the dialog between all actors to instantly check feasibility and optimize against different key performance indicators. Instead of having 10 opinions, you now have one opinion that can be used for benchmarking.

My feeling about the value of optimization technology in an S&OP process is supported by the founders of S&OP, Oliver Wight. On their corporate website (www.oliverwight-eame.com) they offer Supply Chain Design and Optimization services as a practical, proven approach delivering substantial business benefits. ‘Optimization’ is the critical success factor for effective Integrated Business Planning (advanced S&OP).