Scenario Modeling Is Now Crucial for Supply Chain Network Design

The COVID-19 pandemic has exposed many risks and uncertainties in supply chain networks. Materials shortages, demand fluctuations and plant closures have led many organizations to revisit their supplier relationships, as well as distribution and production locations. Evaluating different scenarios helps you gain much-needed network flexibility in these times of stress and can help you prepare for a resilient future. How are companies leveraging scenario modeling for network design and optimization? Read on for common use cases.

Current Technologies in Use for Supply Chain Network Design

Our 2018-2019 Network Design Survey showed that the majority of organizations are still relying on spreadsheets (nearly 60%) and gut feel (15%) to make network design decisions. At the time, only a little over 40% of respondents indicated that they used some form of advanced analytics for decision support. This translates into a lack of agility and speed to decision-making, with most respondents stating that they can only perform network design on a project or periodic basis. For nearly 70% of organizations it takes weeks or days to get key answers to support their decisions. Only 13% get insights in hours.

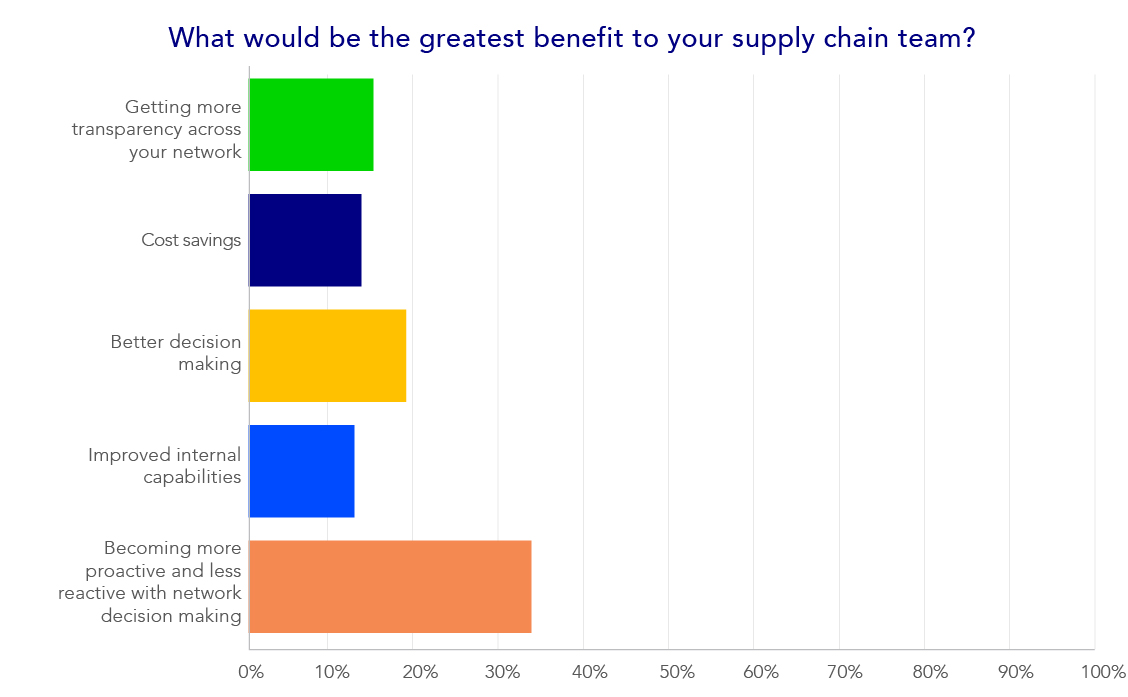

The good news is many of the survey’s respondents recognize the potential of more advanced optimization solutions. Almost 40% stated that they expect to become more proactive and less reactive with this capability. In the context of disruptions like COVID-19, this can make considerable difference, as we’ve seen among AIMMS customers.

Scenarios to assess DC closures and the impact of shutdowns

Prolonged shutdowns have both financial and operational implications, which are often very difficult to assess due to the complexity and far-reaching nature of supply chains. A leading logistics service provider was among the many companies that saw its operations affected by the pandemic. Due to the lockdown, they saw a decrease in demand for one of their business units. At the same time, they faced new constraints on the resource side. They needed to assess if closing some of their distribution centers made sense from a cost stance.

The company modeled scenarios and performed simulations in AIMMS Network Design Navigator with all their products grouped together. They were able to take variable costs, fixed costs, transport costs, different transport types and many other options into account.

In the context of disruptions like COVID-19, scenario modeling can make considerable difference – Tweet this

AIMMS Network Design Navigator allows users to adjust demand for unique customers, locations and products. This means that you can target very specific parts of your demand data and dynamically run different scenarios in those conditions to measure its effect. On top of this, after demand has been adjusted, demand simulations can be run to study the behavior of your resources over time as demand continues to increase or decrease.

Evaluating Potential for Reshoring

Another use case we see for scenario modeling in the current context is evaluating new sourcing locations. A recent Thomas survey found that 64% of manufacturing companies are likely to “bring production and sourcing back to North America” in view of COVID-19. What we’re seeing is not just a trend towards changing materials/part suppliers, but also warehousing and logistics suppliers.

In AIMMS, once you have modeled your current suppliers, resources and customers, you can model new suppliers in your own country and identify which supplier you should select for an optimal cost scenario. The mixed integer programming capabilities in AIMMS Network Design Navigator do the heavy lifting for you, so you can easily identify the most optimal combination of suppliers and resources. You can study optimal sourcing locations while minimizing both production and distribution costs. In addition, you can make certain transportation lanes unavailable and measure the impact.

Using what-if scenarios in the App can help you see the implications of the many uncertainties in your network. What if your demand for a certain product goes up in a given region – will a certain supplier or warehouse become strategically important? What if a warehouse is forced to close, which supplier is most optimal and which customers should be serviced from where? All of these routes between suppliers, resources and customers can be optimized within the app.

Strategic Network Investments

The use of scenarios to evaluate strategic network investments has been common among our customers. A manufacturer of medical equipment was among the many companies that was better prepared to meet disruptions thanks to a previous strategic investment. The OEM had decided to open a large warehouse and leveraged AIMMS Network Design Navigator to assess which products should flow through this warehouse. This put them in a resilient position to face the current crisis.

Network Design does not exist in isolation

Network design is only one of the many pieces of the supply chain planning puzzle. As we’ve seen in the examples above, scenario modeling can be incredibly valuable to optimize this part of the chain. Yet, there is also a tight connection between network design, demand forecasting and Sales & Operations Planning, for instance. Here scenarios can also play a critical role, as we will explore in upcoming articles. Stay tuned!

For more insights on this topic, watch our on-demand webinar “Resilient Supply Chain Network Design.”