Selecting new software for supply chain network design doesn’t have to be a hassle

When it comes to network design, you can’t just set it and forget it anymore. Today’s successful supply chain networks are adaptable. They react swiftly to changing business conditions and customer needs. They scale quickly when there’s opportunity for growth. But network design as a discipline is complex and most organizations struggle to answer network design questions or test hypotheses in weeks. Let alone days, and certainly not hours. Proactive risk assessment rarely occurs. Reactive evaluation post-event is the norm. Technology is part of the problem. As Lora Cecere explains, systems are becoming more complex, “but the primary means to manage trade with network partners is through spreadsheets and email.” This needs to change. Selecting software for supply chain network design doesn’t have to be a hassle.

Technology needs to be more accessible

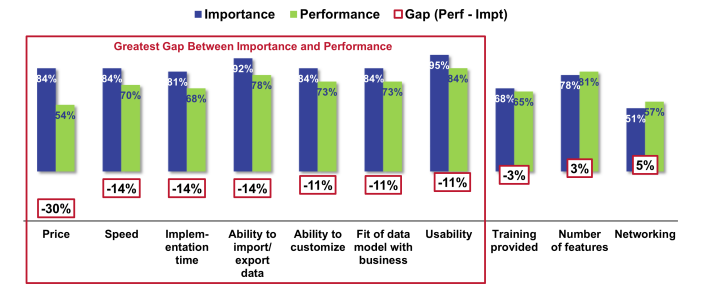

Network design technology has scarcely evolved since the nineties. Implementations are often slow. But perhaps the biggest drawback of commonly used solutions is their price. 84% of respondents in a 2017 study stated that they want an affordable network design solution, but only 54% of them thought available tools meet their price expectation. The result is that most companies stick with spreadsheets.

Point solutions that only address the network design and optimization question may solve the immediate problem of advancing from Excel, but it’s important to consider how they fit into a holistic planning ecosystem. The process of selecting software for supply chain network design needs to change. Drawing on Lora Cecere’s research again, companies are still thinking in transactional terms and not focusing enough on planning data. On top of this, software selection largely follows IT standardization. Only 7% get a test run of the software. Cultural fit between vendors and buyers is rarely considered as well. In the end, supply chain teams get frustrated and sometimes the software gets shelved. There are a few things you can do to avoid this situation.

Here’s what you should consider when choosing a vendor

Our recently published Buyer’s Guide helps supply chain teams find technology to become more proactive and less reactive when it comes to network design and optimization. We developed the Guide based on research conducted among supply chain professionals. The insights we gained led us to develop the following checklist of items you should consider when evaluating and choosing vendors:

- Don’t use a standard RFP approach, take time to define your needs and the capabilities required to support these and then ask vendors to describe how their solution enables those capabilities

- Identify and share your pain points and opportunity areas

- Choose what is right for you…do you want to be self-enabled or do you prefer a solution to be implemented by 3rd parties?

- Form a team that will participate in software selection

- Research available suppliers via analyst recommendations, reports, etc.

- Get demos and pricing structure

- Sign an NDA and share selective data with your preferred candidate(s). They should be prepared to use this to build a POC model, the output from which can be used to support your business case

- Work closely with your leading candidate to truly understand fit, your level of data maturity and a project plan

- Confirm accountabilities across your business and get timeline and resource information

- Get started and capture benefits

Get more insights in the Guide

If you’re curious about what your peers consider valuable when selecting software for supply chain network design and how they rate their network’s maturity, download our Guide. You’ll also find more key characteristics to look for in vendors and how AIMMS is responding to market concerns. Contact us to learn more.