Spending too much time on data crunching, not enough on resilient planning decisions? You’re not alone.

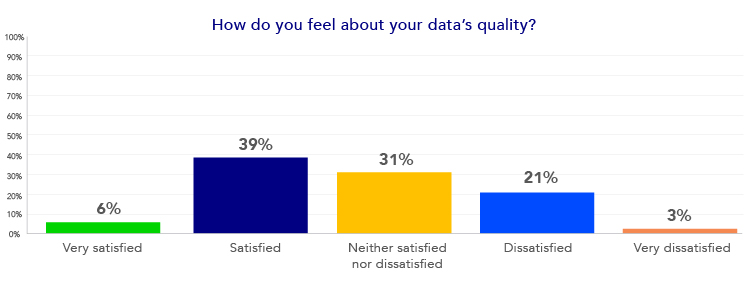

Supply chain data is critical to the planning function. Our recent Planning Maturity Assessment shows that 45% of organizations are satisfied with their data quality, to some degree. 31% a neither satisfied nor dissatisfied. 21% are dissatisfied, and 3% are very dissatisfied. The fact that more than half feel “neutral” or dissatisfied shows data quality is a considerable pain point. How much time are supply chain teams spending on data? Let’s take a look.

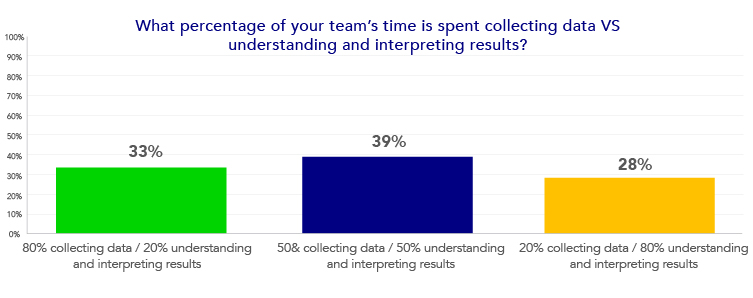

For 33% of organizations, data collection takes about 80% of their time compared to interpreting the data. 28% of respondents are ahead in this regard, spending the majority of their time on interpretation rather than data manipulation. A good amount (39%) are somewhere in the middle.

For 33% of organizations, data collection takes about 80% of their time compared to interpreting the data. – Tweet this

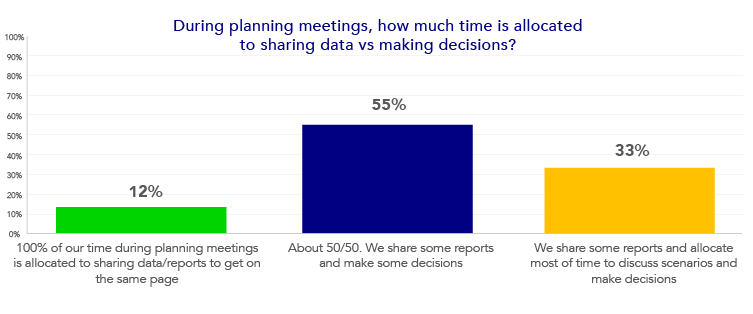

In planning meetings, data sharing seems to be consuming a significant amount of time as well. More than half of the survey’s respondents (55%) stated that their planning meetings are split 50/50 between sharing data and making decisions. 33% of respondents allocate most of their time in meetings to discussing scenarios and decision-making. 12% of respondents stated that 100% of their time during planning meetings is spent on sharing data/results to get on the same page.

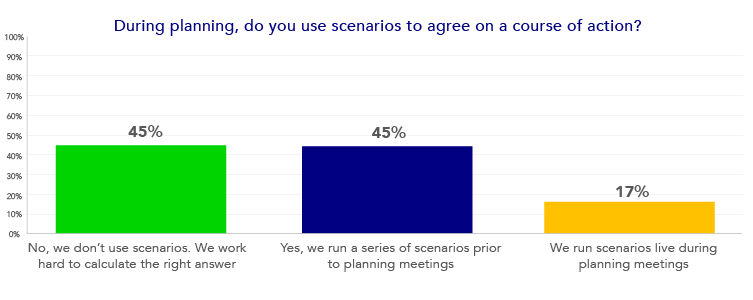

Only 17% of companies run scenarios live during planning meetings. – Tweet this

This focus on data collection may explain why only a small amount of organizations have advanced to using scenario analyses in real-time, during planning meetings. To be precise, 17% of companies run scenarios live. 45% don’t use scenarios at all, but focus rather on calculating a single, right answer. 45% run scenarios before meetings take place.

Scenarios are key to build supply chain resilience

Traditionally, supply chain teams have focused on having perfect data to arrive at accurate supply chain plans. But in today’s uncertain world, striving for accuracy is no longer enough. Data quality is certainly important, but the focus on deterministic planning is not adequate to respond in an agile way to far-reaching disruptions. Gartner advises that organizations embrace resilient planning instead. Gartner defines resilient planning as “mid- and long-term plans that mitigate against uncertainty by ensuring the right degree of resiliency is built in so that short-term plans are more executable” (Gartner, Mastering Uncertainty: The Rise of Resilient Supply Chain Planning, Tim Payne, November 2019).

This type of proactive planning is a result of evaluating multiple future uncertainties through scenario modeling. Such analyses should provide visibility across the entire supply chain and enable users to plan both reactively and proactively. With disruptions like pandemics, politically imposed tariffs or natural disasters becoming more common, we expect more teams to shift towards this capability.

Traditionally, supply chain teams have focused on having perfect data to arrive at accurate supply chain plans. But in today’s uncertain world, striving for accuracy is no longer enough. – Tweet this

Looking to gain more insights on this topic? Download this complimentary Gartner report (available for a limited time) and sign up for our Supply Chain Digest.