Equipping Corporate Sustainability Teams with Supply Chain Planning Tools

Companies are increasingly recognizing the importance of establishing in-house sustainability expertise. Corporate sustainability (CS) teams often focus on setting strategic targets and goals and are responsible for designing and measuring sustainability-based key performance indicators (KPIs). While many companies have internal sustainability targets, there is a growing trend of governmental legislation enforcing the required changes for organizations.

As sustainability targets continue to rise, sustainability practitioners are expected to diligently monitor and improve operational processes, as well as develop strategies that enable their companies to navigate complex climate and sustainability related policies. In the past, the jurisdiction of sustainability teams may have been clear-cut, but it is becoming more challenging to distinguish their focus areas from other domain-specific teams.

A stand-out example would be supply chain operations, which receive significant resources and attention from large companies. From strategic network design to last-mile delivery, these operations are often streamlined and optimized for cost-saving. However, up to 75% of industrial sector CO2 emissions can be attributed to supply chain operations, as highlighted in a recent study by Du & Zhou (2022).

Given that supply chain has such substantial contribution to emissions, CS teams focus heavily on developing strategies to reduce carbon emissions along the supply chain. Supply chain teams often operate as mature business units with access to data and optimization models, enabling them to implement planning initiatives at various levels (strategic, tactical, operational). Conversely, CS teams require access to the same data and models but often need to extract this information from supply chain business units. This approach can be time-intensive and leads to fragmented data and insights.

What are the difficulties for CS teams?

While CS teams may have a clear ambition for their company’s sustainability goals, they often run into challenges when assessing the current state of operations, due to barriers in data accessibility and availability. Difficulties also arise in quantifying the potential impact of their strategies, such as measuring the financial and environmental consequences of switching to more sustainable suppliers or materials. The lack of easy access to data and models makes it challenging for CS practitioners to generate consistent quantitative impact reports, which are crucial for meeting internal and external reporting standards.

How can Supply Chain Optimization software help?

Supply chain optimization and planning software can alleviate challenges in data accessibility and access to decision-making models. Having access to data that represents the current state (or even the strategic plan) for the supply chain network enables CS teams to conduct research using the most up-to-date and reliable information. It also means that they will be able to consider the full scope of supply chain operations. This enables CS practitioners to better integrate existing supply chain operations into their plans, which could reduce the time and iterations to developing practical strategic initiatives.

Having access to the same data and models as supply chain analysts means that strategic initiatives designed by CS teams could be measured on the same KPIs that are already monitored for supply chain planning, as well as new KPIs that are introduced specifically for measuring sustainability goals. Also, this collaborative approach means that CS teams can build strategies that can be supported by the supply chain network. It brings the supply chain and sustainability teams closer together, fostering improved collaboration and reducing the time taken to implement strategic planning initiatives.

Collaborating with SC Navigator

To demonstrate how supply chain and sustainability teams may benefit from sharing data and planning models, consider a CS team at a company with a global supply chain, who wanted to explore decarbonization pathways. They realized that load sizes could be adjusted to reduce CO2 emissions from some transport routes by up to 25%. They could also upgrade some of their production facilities with new machines to reduce scope 1 CO2 emissions.

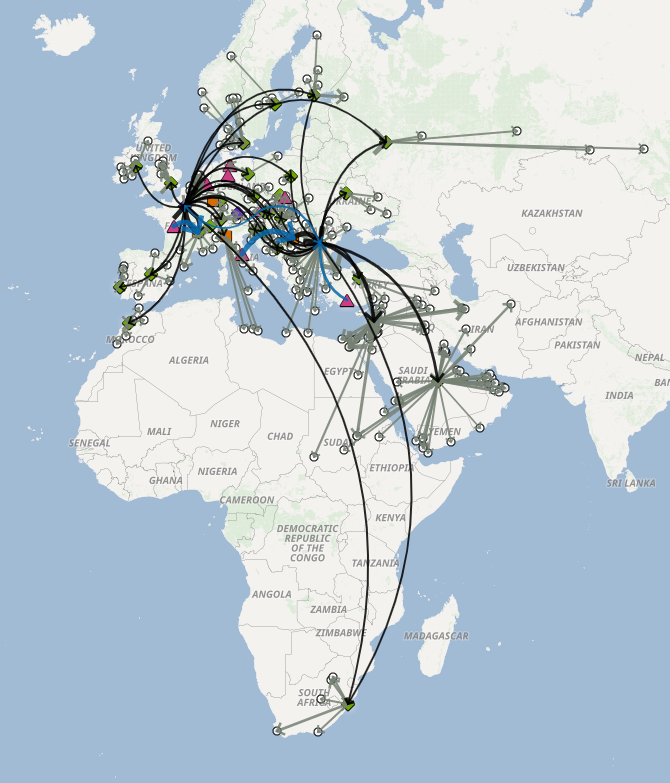

With a tool such as SC Navigator, the CS team would have access to the current state of the supply chain network. In this case, the optimized network is distributed over the EMEA (Europe, Middle East, and Africa) region:

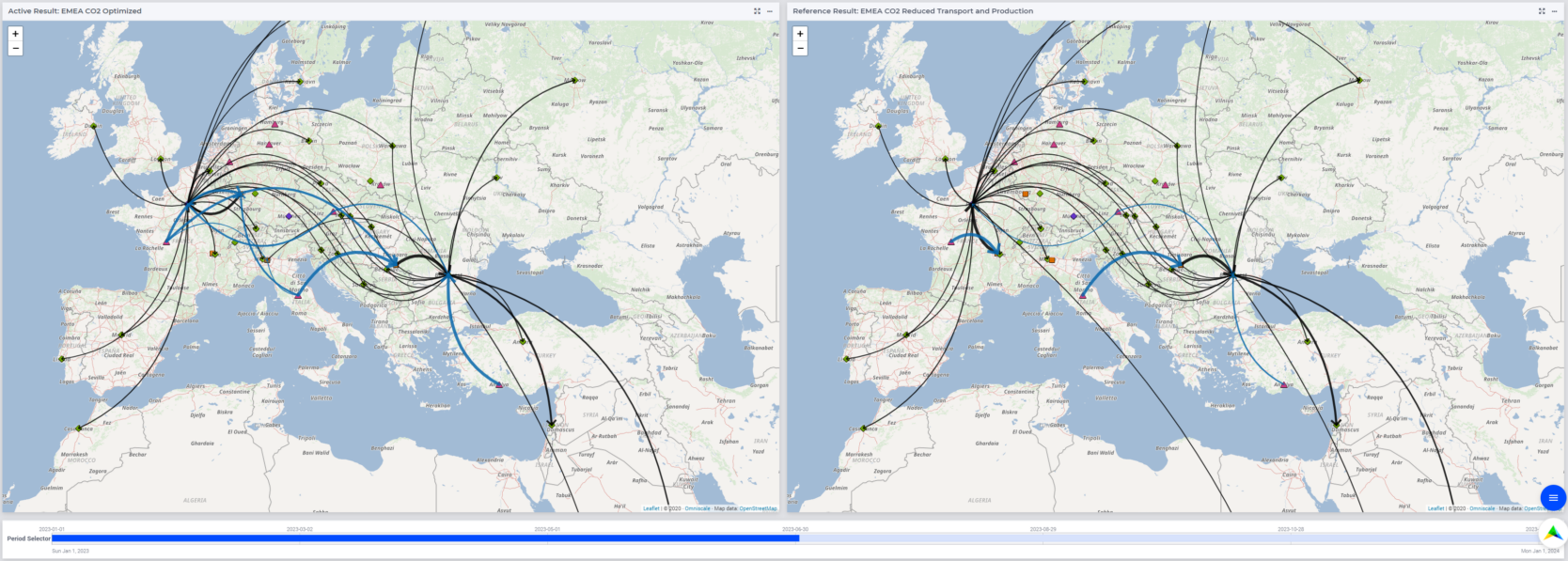

The CS team would be able to adjust or introduce custom objectives in the optimization model, allowing them to re-optimize the supply chain network to measure the impact of the identified decarbonization pathways. They would then be able to compare the optimal network footprint with their proposed strategy. The screenshot below shows a comparison between the existing supply chain (left) and the supply chain after the new strategy has been implemented (right):

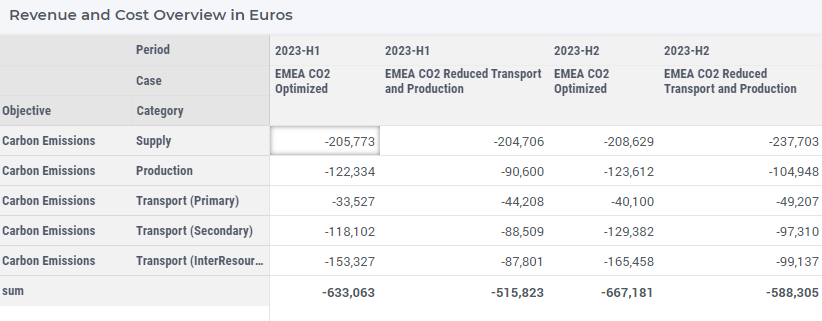

Consolidated reports, such as the one shown below, give a quantitative breakdown of the impact of decarbonization pathways. In this case, two scenarios are compared: EMEA CO2 Optimized (the existing supply chain network optimized for reducing CO2 emissions) and EMEA CO2 Reduced Transport and Production (which contains the updated load sizing and improvements to the production methods).

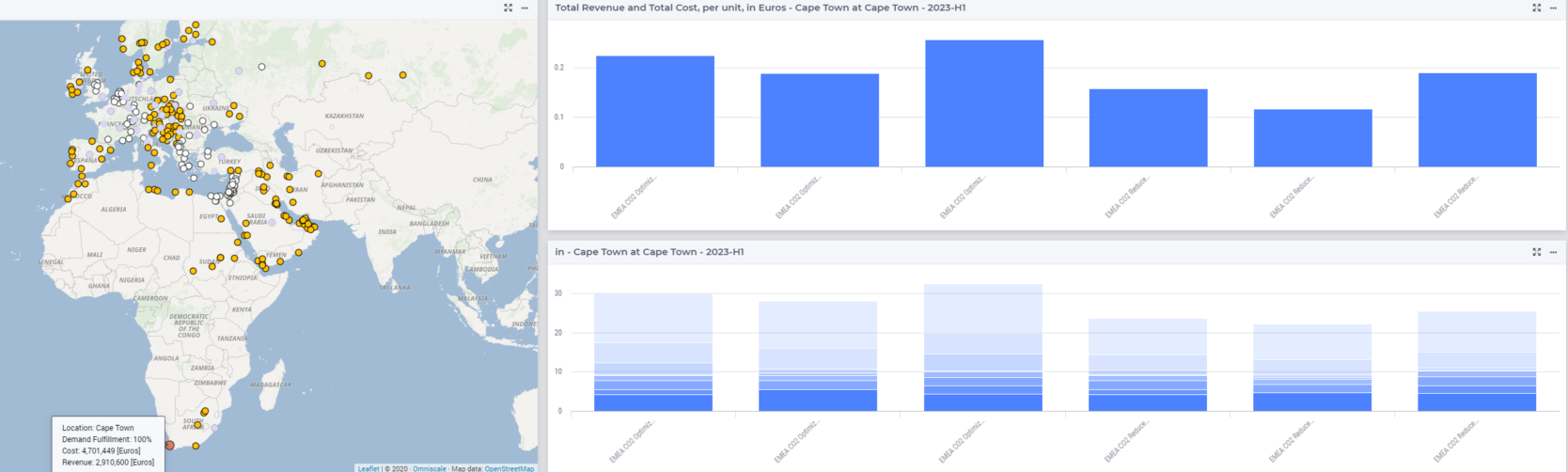

If the strategy is applied, the sustainability team’s proposal clearly results in a significant reduction of CO2. SC Navigator provides detailed summaries of the cost of the optimized supply chain network, including cost-to-serve (a breakdown of the costs to serve a specific customer), end-to-end reports (the flow of materials through the network to meet the demand of a specific customer, or group thereof), and KPI summaries.

Collaboration between supply chain and CS teams allows them to work towards common strategic goals, as well as enabling supply chain teams to easily incorporate the custom objectives (and associated KPIs) set by sustainability teams into their operational, tactical, and strategic decision-making models.

Although this is a simple example of a use case for sustainability teams, it demonstrates the benefits of having shared data and models between supply chain teams and sustainability-focused teams.

Conclusion

The difficulties faced by CS teams are primarily data accessibility and availability, as well as measuring the impact of CS strategies. Supply chain software can help by providing CS teams with access to up-to-date and reliable data, enabling CS teams to measure the impact of strategic sustainability initiatives and better integrate existing supply chain operations into their plans.

Collaboration between CS and supply chain teams allows for shared data and planning models and reduces the time taken to design and iterate strategic planning initiatives. With shared data and models, CS and supply chain teams can work towards common goals, while the supply chain teams can easily incorporate sustainability objectives into their decision-making models. This collaboration benefits both teams and enables more effective strategic sustainability planning and implementation.

If you want to learn more, we wrote an in-depth whitepaper that covers the sustainability aspect of supply chain optimization. Click on the image below to download the guide.