“Innovation differs from invention in that innovation refers to the use of a novel idea or method, whereas invention refers more directly to the creation of the idea or method itself. Innovation differs from improvement in that innovation refers to the notion of doing something different rather than doing the same thing better.” – Wikipedia on “Innovation”

This year’s Gartner summit gravitated strongly towards innovation. In terms of their DDVN (Demand Driven Value Network) maturity model, they focused on the deployment of relatively new ideas or methods on Stage 4. In their language, the focus was on progressing from an ‘Integrated’ supply chain to a ‘Collaborative’ supply chain. Steps in the process fall into two categories: those that work on enabling collaboration, and those that seek to get value out of collaboration.

Interesting as they are, the finding that intrigued me the most at the conference was the struggle to find the right supportive technology. With each conversation we had, be it with companies or analysts, the point was being made that progress had been delayed by the struggle to find the right technology.

Gartner indicated that around 65% of companies are still at DDVN maturity stage 1 or 2. In other words, they do not have an enterprise-wide planning process that brings viewpoints from various supply chain functions within the company together. The conference provided several presentations on improving your business planning process. Despite this, innovations had the upper hand and presentations on innovation offered a pleasant mix of theory, concepts and practical cases.

Innovations that were highlighted at they Gartner conference include:

- Segmentation – Organizations are embarking on cross-functional segmentation efforts to reduce overall complexity. Value chains are segmented to manage similar clusters to do the same. Companies start working with customers and suppliers to build inter-enterprise processes, such as collaborative forecasting and inventory management. Technology enablement focuses on building connectivity with trading partners, as well as supporting cross-functional trade-offs between supply chain and other functional areas. It is that latter part, where we felt that companies struggle to find the best way forward. The only technology mentioned being used was Excel.

- Cost-to-Serve – Organizations are increasingly looking for ways to get higher visibility into their CtS. Improvements are initially identified after obtaining in-depth visibility into cost components. As soon as the insights have been obtained, the need emerges to harness the value of that insight, by means of what is called ‘Advanced Analytics.’ This enables companies to find ways to improve their CtS in line with their strategic objectives. It is easy to predict that as soon as the analytics to support that have been made available, the question of embedding the insights provided by the analytics into the daily workflow of decision makers will emerge. Commercial off-the-Shelf (COTS) supply chain software vendors do have good solutions for visualizing the CtS, and an occasional front-runner claims to have found the answer for improving your CtS. However, thus far no COTS vendor provides an answer for embedding CtS optimization into your regular business planning process.

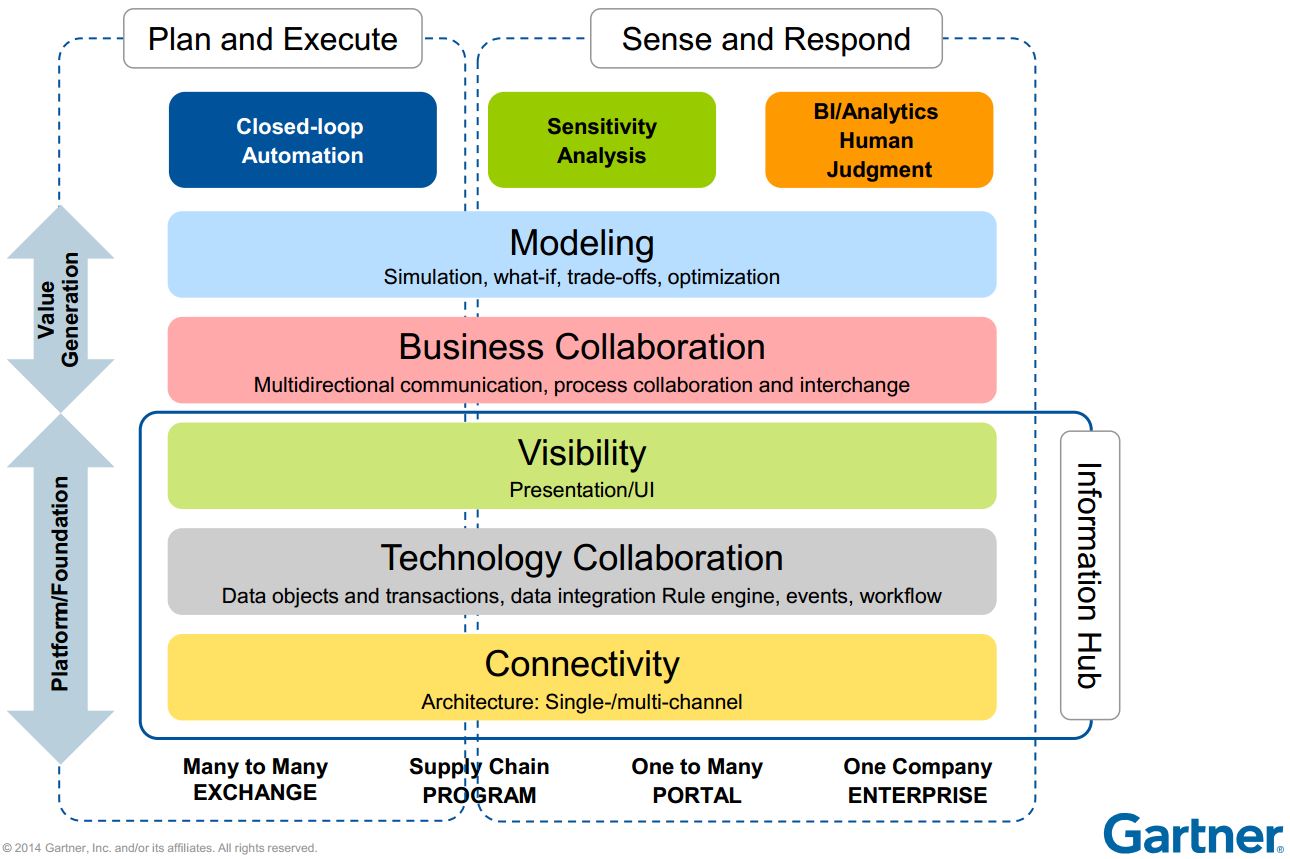

- Supply Chain Visibility – Gartner definition: “The aim of end-to-end supply chain visibility (E2ESCV) is providing controlled access and transparency to accurate, timely, and complete plans, events and data — transactions, content, and relevant supply chain information — within and across organizations and services operating supply chains.” As you can see in the picture below, the definition is centered on the functionality of the bottom 3 layers, forming the Information Hub. Most providers focus on that Hub role, in the form of a cloud-based service.

- Supply Chain Talent – With supply chains moving more and more towards the heart of the company, attracting, growing and leveraging top talent is of eminent importance. In addition, we can witness a growing synergy between the world of operations and the world of analytics, raising the bar for supply chain staff to be savvy in applying analytics in the supply chain field.

Finding the right technology

Despite the growing importance of these and other innovations in supply chain planning, most companies still struggle to find right technology to take their supply chain efforts to the next stage of improvement. The vast majority of businesses are still using Excel, supported by a COTS solution for additional functionalities.

The struggle is fueled by three causes:

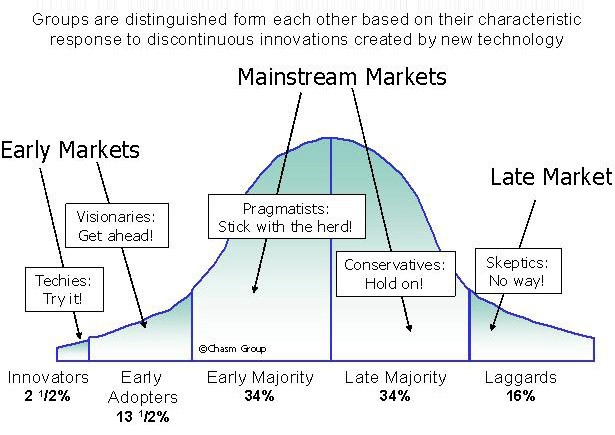

- Inability to find COTS software that supports their innovation. This is not unusual. COTS vendors typically focus on serving the ‘early majority,’ so trailing the ‘innovators’ and ‘early adopters’ in the innovation process.

- Internal improvement processes to purchase software package. Many larger corporates maintain a strong pressure to reduce the number of software packages and vendors, thereby slowing down innovation to the pace of their current vendors. These typically consist of large ERP providers surrounded by a few certified siblings, who jointly have to maintain a huge legacy in software. This policy typically dissolves the ambition for innovation.

- Difficulty fitting a solution into the existing IT landscape. Even when companies succeed in finding the best COTS solution, they face the challenge of integrating that solution into their existing IT landscape. Processes need to be re-aligned, master data assigned to new owners, users need to adapt to new user interfaces, all dictated by the structure embedded into the new COTS solution.

What you would want to have is a technology that allows you to do the following:

- Quickly create a prototype of a new and innovative planning idea, to test the concept and verify its feasibility;

- If positive, develop the idea further into a prototype, to explore the potential business value, and initiate building understanding, support and momentum for the new idea. For this stage, a practical user interface plus a flexible decision support engine is crucial;

- Suppose you get all thumbs up, as in that the concept seems to fit the business and provide the necessary value, you would ideally continue in the same quick and explorative way to develop your first actual end-user application.

- You would then be able to scale that end-user application to whatever dimension in any direction, be it geographical, number of users, size of dataset, etc.

- To close off, what you would want is that each time you start a new innovation process, you don’t need to go through a long an tiring process of getting approval to start find new software; No, you can start right away, because the innovation technology is already there.

This is exactly what made companies like Johnson & Johnson, Kroger, Nike, Papyrus, Zalando and BP choose AIMMS; it is their catalyst for innovation! One of them has modelled an application that allows users around the world to do Cost-to-Serve analysis. Not as a one-off analytics exercise, but as a regular process embedded into the daily operations. Another company has built an application that brings them central visibility AND control over their EMEA supply chain operations. It draws data from various operational systems, providing a visibility platform to decide on a daily basis of replenishment, inventory levels, transport flows and client to warehouse allocation. Yet another company developed a pricing model, to determine optimal product price levels, considering geography, product group, client category, and stage in product life cycle. By doing so they venture into the stage beyond ‘just’ segmentation.

Finally, regarding the Gartner topic on talent development; wouldn’t you want to work in an inspiring supply chain organization that continuously pushes the frontier of supply chain management? It allows you to engage in an endless process of self-development.

So, the key-learning for me from the Gartner conference is this: what do companies need to stay ahead of the competition? They need to stop searching for an Off-the-Shelf software package to support their innovations. They need to stop fumbling around with spread sheet tools. Instead, should they take their future into their own hands, and adopt a modeling technology that supports them all the way.

Get a roundup of our best supply chain content every month in your inbox! Sign up for our blog digest here.