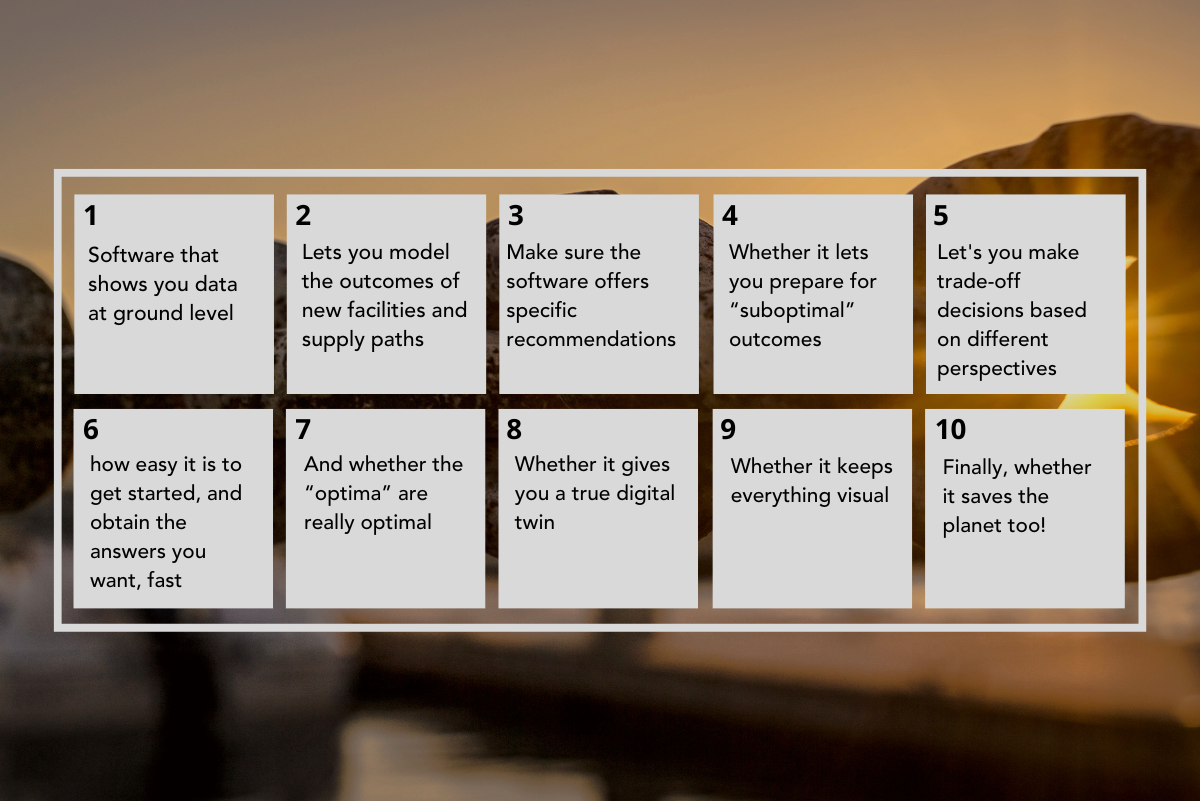

10 Things to Consider When Choosing a Supply Chain Network Design Software

At AIMMS, we often hear the question “When do I need supply chain network design software?” from those involved in the supply chain space. The easiest answer would be “Before you think you need it.”

But that’s not exactly helpful in your day-to-day.

Because many supply chains aren’t so much designed as evolved. Starting small, gaining complexity, then getting less efficient as conditions change and risks arise, with each new requirement added on top rather than designed in. And before you know it, your supply web spans multiple countries, hundreds of product lines, and thousands of in-market variants each with its own path of inputs and outputs needing optimization.

There’s no point where you could look back and say, “That’s when I needed it.”

So exactly when do you need Supply Chain Network Design Software?

Here’s a more helpful definition: you need supply chain network design (SCND) software at the point where your process stops looking like a chain and starts looking like a web. Because a web (or network) is multidimensional; an event in one pathway can transform outcomes elsewhere in the ecosystem, and not always for the better. This level of complexity is the norm for almost all multinational organizations.

If you’d prefer something visual, check out our webinar Supply Chain Network Design: What are your options instead?

At this point, your supply chain doesn’t just need optimizing; it needs redesigning. The improvements you need to stay competitive aren’t just a percentage point here or there; they’re wholesale transformations that accommodate new risks and scenarios.

That’s what our SCND solution does – so, based on the challenges we see among some of our customers we’ve listed the factors you need to consider when choosing your SCND platform.

1. Excel is good… but not that good!

Some surprisingly large supply chain networks are still managed on Excel. Now don’t get us wrong: we love Excel. It’s an extraordinary desktop tool that can do amazing things. But ultimately, it’s still a spreadsheet, not able to calculate with constraints, variables, and objectives, not to mention version control and lack of collaboration options.

Based on our research, 60% of SCM professionals rely on spreadsheets. Learn more in our Supply Chain Network Design Buyer’s Guide.

Imagine a monster spreadsheet combining numbers from twenty distribution centers. You want to know what’ll happen if one facility is lost to a natural disaster, or suffers a strike, or borders close around it. Delete the DC in Excel, and all you’ll see is a sea of #VALUE! errors, the data you’re working on hasn’t just changed – a critical part of your supply chain has simply gone away.

Imagine a monster spreadsheet combining numbers from twenty distribution centers. You want to know what’ll happen if one facility is lost to a natural disaster, or suffers a strike, or borders close around it. Delete the DC in Excel, and all you’ll see is a sea of #VALUE! errors, the data you’re working on hasn’t just changed – a critical part of your supply chain has simply gone away.

Solving this means reframing the approach. Rather than use data at ground level, you need a bird’s-eye-view: seeing the supply web from above, showing you the big picture and the forces acting on it.

Modeling your network in this way is a better way when it comes to redesigning your supply chain because it lets you test scenarios, push capacities beyond their limits, and see what happens when rare but cataclysmic disasters occur. (Like that East Coast distribution center going up in smoke) and not all SCND applications do this well.

So that’s the first and most important feature to look for: does the application give you that 30,000ft view from above, where you can model the chain process as an integrated whole, with visualizations that make it comprehensible? That’s the start of real supply chain network design.

2. Whether you need to know what *could be*, as well as what *is*…

Business transformation is about exploring new territory – what you could be doing, not just what you are. Building a new factory or setting up a shop in a State, in which you’ve never done business before, isn’t a singular business case; it’s a change in your operational model that affects hundreds of processes.

So as our second consideration, make sure your supply chain network design software lets you model the outcomes of new facilities and supply paths, however weird. What if your principal DC wasn’t near a national transport hub? (It’s worth checking whether the high costs of being in Atlanta or Singapore are justified by your shipping volumes, at least.) What if your new building wasn’t downtown, but in a suburban center instead, with the square footage to expand? What if, what if, what if…

AIMMS Supply Chain Network Design, of course, lets you try out your ideas without side effects. Create the process in your network design digital twin, link it to its inputs and outputs, and see whether it fits. For many people experienced in supply chain network optimization, this high-level modeling is all that’s needed to get a strong sense of what might work and what definitely won’t.

3. …and go beyond that, to what you *should* do

Modeling the outcomes of putting a new facility in the Nordics is straightforward. But industrial-strength SCND software goes much further. Ideally, you want your model to tell you what’s going to work… without having to specify the solution yourself.

“There are plenty of ways to work out how to save 1% here and streamline resources there. Far fewer solutions can tell you: where should I build my next factory? In other words: get recommendations” – Paul van Nierop, Product Owner Supply Chain at AIMMS.

Doing so doesn’t need exotic AI, just smart optimization algorithms that meet the criteria you give it. It’s the flip side of What-Ifs: instead of “What happens if I put a production unit in Stuttgart”, it’s more “Where on this transport network is the most cost-effective place for a site?” Make sure your SCND offers specific recommendations.

4. Whether it lets you prepare for “suboptimal” outcomes?

A reminder: just as a good SCND platform lets you add things in, it needs to show you what happens if you take them away. Perhaps as game-changing as a natural disaster in a nearby state… or as humdrum as an equipment breakdown that takes months to fix. Resilience needs to be part of every functional supply chain network.

5. …and make trade-off decisions from various perspectives

Of course, the “right” model isn’t the same for all circumstances – not even for the same company at different times. Strategic priorities may change; perhaps you’re looking to run down one BU in a line of business you now no longer want. Or you want to invest heavily in an innovative new product, and losses, for now, can be tolerated.

So do ensure the supply chain network design software you’re looking at can handle these different perspectives and KPIs in optimization. It’s not always about cost and profit; your business has longer-term objectives like service levels and carbon emissions… and your SCND must take them into account. Heard enough already?

6. If it needs months of integration work or not…

SCND is more strategic and tactical than operational. That means you shouldn’t have to connect it to every last data source in your ERP, every last number in your financials. It’s a big-picture tool, and it needs to let you start work without getting bogged down in every tiny detail.

Consider whether your current SCND software (or Excel) offers this… and how easy it is to get started, and obtain the answers you want, fast.

7. And whether the “optima” are really optimal

It may look great that you’ve found a scenario where resource utilization, production throughput, and cost models can’t be improved any further. The problem is, that “optimization” may be excessively brittle. A single shock to the system – and not necessarily a big one – will tear that ultra-lean, super-taut process pathway into small bloody chunks.

That’s why a lot of optima aren’t the best choice in the real world. And plenty of supply chain models have tripped up here, by over-optimizing specific processes to the point where they can’t handle even small deviations from perfect conditions. Again, ask if your SCND software is up to the job. Can you run scenarios to find a solution that is slightly sub-optimal but far more robust?

8. Whether it gives you a true digital twin!

Everyone’s heard of Digital Twins by now: all your interacting business processes are mapped in software, so you can poke and prod to see what happens before making a change in the real world. But not all digital twins are born equal.

The best digital twin isn’t a sketch; it’s an idealized image of your business, reflecting the resources and financials flowing around your organization. At a minimum, it needs to be a digital snapshot of your supply chain at the strategic level (suppliers, production facilities, warehouses, modes of transport, and customers) showing how these supply chain entities are interconnected. This allows you to run what-if scenarios against the digital twin which answers the “so-what” question: what should I do about it?

9. And whether it keeps everything visual!

SCND is a complex task, and SCND software does complex things. But the outputs it gives shouldn’t be complex at all. They should be as clear and obvious to a junior analytics hire as to the global supply chain manager. And that means getting visual.

So as our penultimate point, consider if the software you’re mulling over presents its data in an informative, intelligible, and even enjoyable form. One that doesn’t give you headaches or make you scroll through endless sheets, but gives you a visual map of where your resources are with a clear connection to the real world.

10. Finally: whether it saves the planet too!

That’s a dramatic way of wording it, but let’s remember every company of size today has ESG and CSR goals – and meeting them may soon be a legal requirement and financial imperative, not just a company policy.

Success metrics include carbon footprints. But it may also be about meeting Living Wage levels or achieving a percentage of recycled inputs, or energy or water consumption. We don’t need to tell you which SCND software makes this a core feature – but if there are others on your consideration list, make sure they do too.

As a next step, why not download our guide to doing it, “Implementing Supply Chain Network Design”?

Check every box with AIMMS

While no list will ever be complete, the points above will get you started. And it’s hardly surprising that one solution able to address all 10 is AIMMS’ own solution for SCND. With an intuitive visual interface, cutting-edge mathematical optimization models, and a huge set of criteria to choose from when making decisions, it’s the choice of some of the world’s most demanding supply chain professionals. To back that up, take a look at some of our Case Studies.

So if you’re unsatisfied with your current solution – whether it’s a SaaS platform like us or a mass of Excel spreadsheets like so many companies, we’d love to talk. Schedule a demo today.