Best Practices to Model Carbon Costs in Supply Chain Network Design

Traditionally, supply chain network design focused on optimizing costs and service levels. After the upheaval in 2020, designing for resilience and agility has become more common. Going forward, another dimension will require more attention: designing for sustainability and responsible business. If you are looking to model the environmental impact of your supply chain and make more sustainable decisions, modeling carbon costs can be a useful starting point. In this blog post, we share best practices for modeling carbon costs in network design.

The case for sustainable supply chains

Even before the COVID-19 pandemic, many companies recognized the need to relook at their supply chain with an eye on environmental impact. The drivers behind this vary. Customers prefer to buy sustainable and ethically sourced products. There is also increasing government regulation. In April this year, the European Commission adopted a proposal for a Corporate Sustainability Reporting Directive (CSRD), which introduces detailed sustainability reporting requirements for large and stock-listed companies. Moreover, there’s compelling opportunities for product innovation in this area. Many companies that recognized this need have been experimenting with carbon costs.

What are carbon costs?

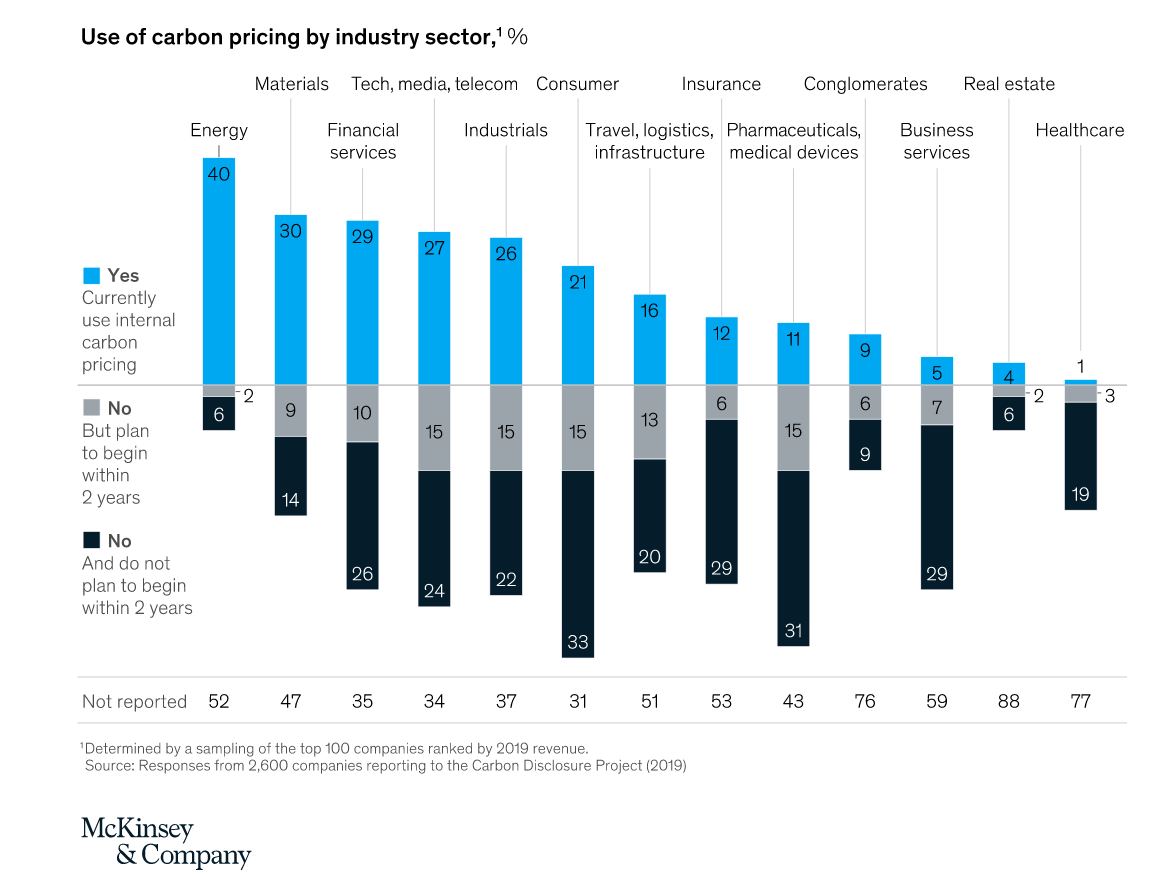

As McKinsey states, carbon costs set “an internal charge on the amount of carbon dioxide emitted from assets and investment projects.” This metric helps companies assess “how, where, and when their emissions could affect their profit-and-loss (P&L) statements and investment choices.” According to the firm’s 2019 Carbon Disclosure Project, 23% out of 2,600 companies surveyed are using an internal carbon charge, and another 22% planned to do so in the next two years. Of the top 100 companies in their global data set, the companies that reported using carbon costs are mostly in the energy, materials, and financial industries. They were followed closely by the technology and industrial sectors, as shown in the graph below. In Europe, 28% of companies are already using internal carbon pricing.

In Europe, 28% of companies are already using internal carbon pricing

How do you model carbon costs?

At AIMMS, we are enabling this type of modeling for companies using our supply chain network design application. While we will release more functionality to support this in the future, custom costs in our app already allow companies to start modeling environmental impact. Network analysts/modelers can simply create a custom cost in our data import wizard and call it “carbon costs.” This allows them to indicate at which points in the supply chain carbon emissions occur.

To introduce them in network models, we advise you to:

- Use publicly available data on emission factors to calculate the carbon tons emitted by the activities in your supply chain. For instance, you can use data from the Environmental Protection Agency in the U.S. or the UK Government’s conversion factors for company reporting on greenhouse gas emissions.

- Use a publicly available source of carbon pricing to convert the carbon tons to carbon costs. This article by McKinsey can be helpful to understand how other companies are doing this. Danone, for instance, publicly reports its carbon-adjusted earnings per share (EPS) using an internal carbon pricing of €35 per metric ton emitted. Other companies have chosen to set their thresholds at $40 per metric ton. This may not be enough to account for other externalities, and as the High-Level Commission on Carbon Prices explains, it will need to increase to $100 per metric ton by 2030 to meet the standards set in the Paris Climate Agreement.

- Once you have converted the carbon tons to carbon costs, change them into cost coefficients per unit of activity, and capture these in your model.

AIMMS customers can then use scenarios to assess the impact of carbon costs. For example, they can:

- Optimize for physical costs only

- Optimize for carbon costs only

- Optimize for physical and carbon costs

- Compare the scenarios to see how much additional physical costs you will incur if you optimize carbon costs, and how much additional carbon costs you will incur if you optimize for physical costs.

Supporting your sustainability initiatives

We intend to build out more carbon modeling functionality in AIMMS Network Design in the second half of 2021. For instance, we will enable customers to capture emission factors in the model in order to quantify carbon emissions in tons instead of currency. We will then add the ability to apply constraints on the tons emitted, while at the same time minimizing costs and optimizing service levels.

This will enable you to run scenarios to achieve the right balance between sustainability and cost. So, instead of minimizing carbon emissions and incurring a massive cost penalty, you will be able to find solutions that have a very large carbon reduction impact, but with a reasonable increase in costs.

We are working closely with customers who have corporate carbon footprint goals to ensure that the functionality we build is of immediate relevance to them.

We hope this article provides a concrete way to start modeling the impact of carbon in your supply chain network design. If you have questions about using AIMMS for this purpose, contact us or leave a comment below.

What our readers are saying

Comments are closed.

Good Evening,

I thought this was a good article. Do you have a more detailed white paper on the carbon coefficient and potientially the impact of the 2030 standards on ground transportation power unit fuel efficiency and the impact. Thank You Laurie Copeland