What is a Digital Supply Chain Twin and How can it Support Your Strategic Decisions?

Gartner first coined the term “digital supply chain twin” in 2018. Since then, there’s been a lot of confusion in the market about what it means. In this article, we will look at what a digital supply chain twin is, how it can help you make better strategic decisions, and how you can start building this capability.

What exactly is a Digital Supply Chain Twin?

To answer this question, let’s first unpack what a digital twin is. A digital twin is a near-real-time virtual representation of a physical object or process. The concept was originally developed by Michael Grieves, a thought leader in product lifecycle management. In manufacturing, digital twins are often used to model complex assets to understand their behavior over time and improve asset maintenance and design. By feeding real-time data to the model using sensors and applying advanced analytics capabilities, engineers can identify behavioral characteristics and trends to improve the asset’s overall performance. This same approach can be applied on a larger scale. For instance, by applying it to multiple assets in order to model a complete manufacturing process.

A digital supply chain twin, as defined by Gartner, is “a digital representation of the physical supply chain that can be used to create plans and make decisions.”

Much like the example of above, a digital supply chain twin can help supply chain leaders use resources more effectively and make decisions that are better aligned with corporate objectives. Let’s look at a practical application.

Amidst constant change, the digital twin technology implementation can result in a remarkable revenue increase of up to 10%, a substantial reduction of time to market by as much as 50%, and a remarkable improvement in product quality of up to 25%, as reported by McKinsey.

Improving strategic network design decisions with a digital supply chain twin

One of the common applications of a digital supply chain twin is building a digital representation of your supply chain network. This digital representation should be a living and breathing model that considers:

- All the different components in your supply chain network (for instance, your products, customers and distribution centers),

- the relationships between them (for instance, which facility produces which product),

- and the rules and constraints that govern those relationships (for instance, lead times, maximum inventory holding, production constraints).

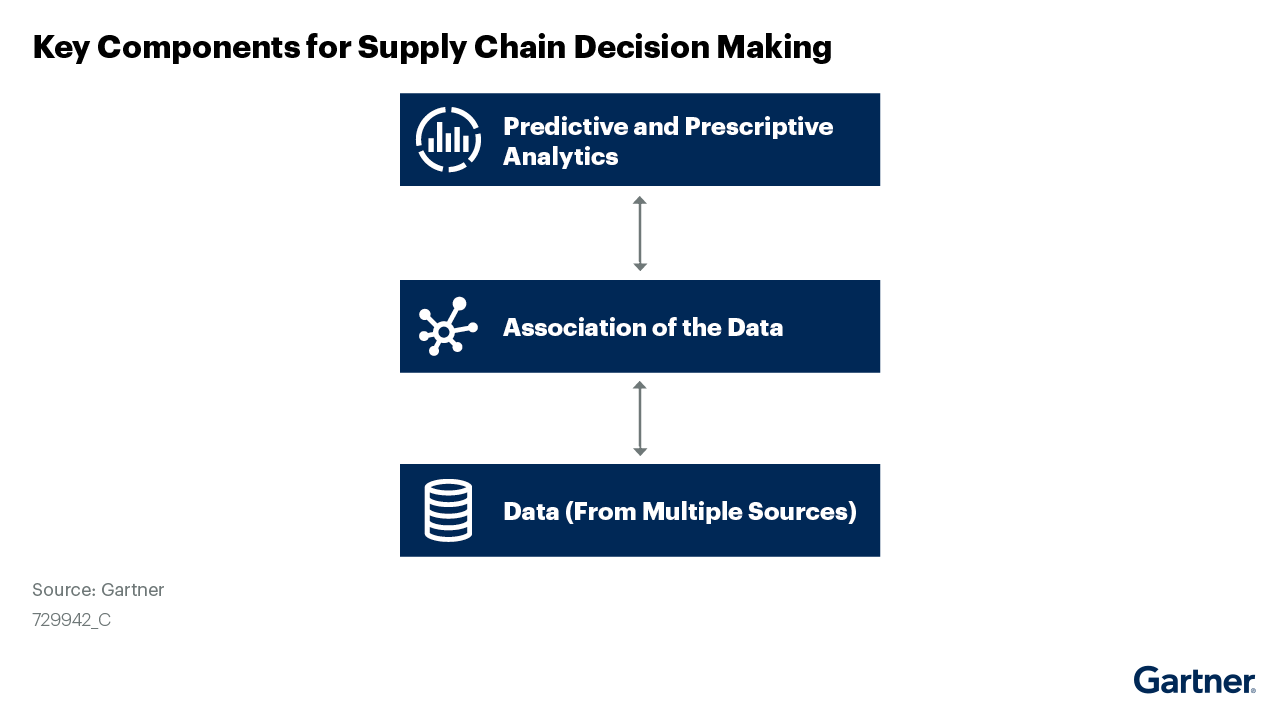

It should also include robust visualization capabilities to help you visualize these components, relationships and constraints in an intuitive way. To support your supply chain planning practice, you can enhance this digital representation with scenario modeling and prescriptive analytics. This allows you to test different assumptions or configurations and get recommendations to achieve a given objective, such as lowering costs or improving service levels.

Identifying cost savings in supply chain network design

Let’s say you want to identify cost saving opportunities in your supply chain network. Once you have modeled your current network in the digital twin, you can:

- Relax transport constraints to see if you can allocate customers to different service locations in order to optimize costs.

- Relax DC capacity constraints to see if you can shift volumes between locations to save costs. This will also reveal how much additional capacity you need to make these shifts, and whether it is worth the CAPEX investment.

- Relax supplier and production constraints to see if any shifts in supplier and production volumes deliver any cost improvements.

- Simulate different supplier issues and the impact on your business

- Change regional or category-based demand profiles and understand the impact on your supply chain

Modeling non-financial objectives

The same methodology can be applied to non-financial objectives. For instance, if sustainability is an important directive in your company, you can use the digital supply chain twin to model:

- How relocating your production locations would impact carbon emissions (for example to drive fewer miles)

- The impact of prioritizing products that are both high-performing and low on carbon

Such network design decisions are generally strategic in nature, and don’t require the level of detail needed for more operational planning purposes. This makes supply chain network design a very interesting starting point to create your digital supply chain twin. There are some other best practices you should consider.

Getting started with a digital supply chain twin: practical considerations

Gartner outlines three different ways organizations typically get started with a digital supply chain twin:

- Building a model that focuses on a particular functional area

- Building an end-to-end model that can support tactical/strategic decision making

- Building a domain-specific model that focuses on short-term decision making with frequent updates from execution (for example, a model that might “predict short-term stock-outs across the supply chain”)

In our view, building a model of your supply chain network that can support strategic decisions is a great way to start your journey. It simultaneously addresses your immediate network design needs while building and investing in a digital twin that will take strategic decisions to a new level in the future.

Get started quickly with Supply Chain Digital Twin as a Service

Looking to ramp up quickly and start experimenting with a supply chain digital twin? Stay tuned for another blog on our progress with several clients engaging in digital twin as a service.

For more on this topic, check out our Digital Twin offering.