Bespoke Production Planning & Scheduling Apps

Production planning is a strategic activity that aims to determine the optimal allocation of employees, materials and production capacity to serve customers. A production schedule is essentially the short-term execution of the production plan. There are many different constraints to consider in production planning and scheduling. These constraints can be extremely complex and are often very specific to the company’s production process, making it an ideal problem to tackle with optimization models. With AIMMS, you can develop and deploy mathematical optimization apps to achieve your organization’s unique objectives with clarity of implications and trade-offs.

Improve on-time demand fulfillment

Maximize resource utilization

Reduce planning time

Lower costs

Customer Stories

Profitable Production Planning at Nampak

The need for flexibility and production efficiency, paired with rising demand volatility, compelled Nampak Glass to improve their production schedule. Nampak chose AIMMS’ optimization software and Districon, an AIMMS implementation partner, to develop a profit-based optimization solution for the detailed planning and scheduling of glass bottles in the company’s 3 furnaces – amounting to a total of over 1000 production tons a day.

INEOS Köln achieves over 90% Plant Utilization

After implementing an AIMMS-based production planning system, INEOS Köln has become one of the most effective petrochemical sites on the planet. Bottlenecks are foreseen at an early stage, allowing INEOS to take appropriate preventive actions and minimize losses in utilization.

Production Scheduling for a Leading Beer Manufacturer

This beer brewer is one of the world’s largest. They have over 200 breweries and hundreds of brands with global appeal. They wanted to optimize production scheduling to maximize the utilization of their brewing tanks and improve demand fulfillment. They approached ITC Infotech, a technology services leader and AIMMS implementation partner, to develop a custom optimization application.

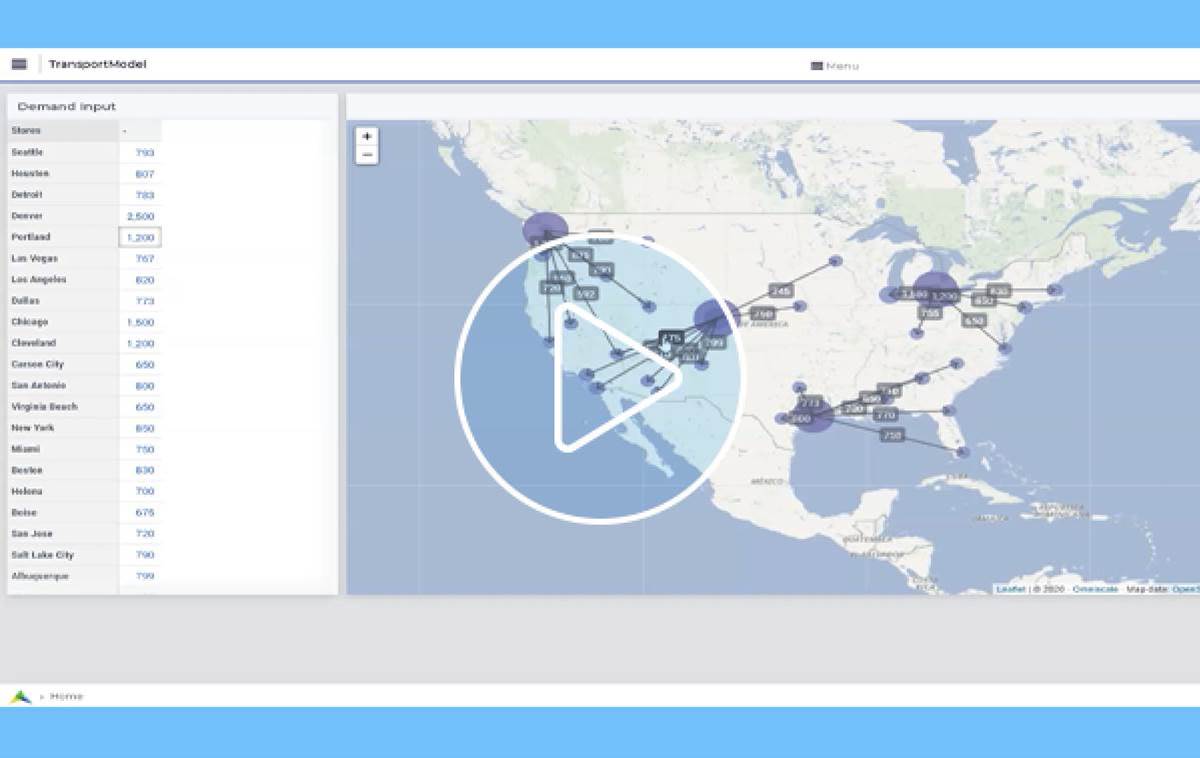

AIMMS offers you a toolkit for rapid optimization modeling and app development

Get started with an example

Develop in-house or outsource to a partner

There are different implementation approaches you can take to benefit from optimization. We have a large ecosystem of partners that specializes in the development of AIMMS-based optimization apps.