An interview with Boon Edam’s Aron Waas

An interview with Boon Edam’s Aron Waas

Implementing Sales and Operations Planning has many benefits. To truly leverage it to improve business performance and predictability, you need to embark on a change management process and you need the right technology to self-enable your team. Often, teams think they also need plenty of clean and accurate data to do it right. But starting small can pay off. We spoke with Aron Waas, Global Supply Chain Director at Royal Boon Edam International to hear about his company’s experience.

Hello Aron, can you tell me more about Boon Edam and your role as Global Supply Chain Director?

Boon Edam is a private, family-owned company that is over 140 years old. We are a manufacturer of premium entry systems, such as revolving doors and security access gates. We have 3 factories, one in USA, one in China and one in the Netherlands (in the city of Edam). We have over 20 sales subsidiaries and, at this stage, 3 different Distribution & Support Centers. These centers (or D&SCs) support our sales subsidiaries with all their inquiries, service requests and the delivery of products and services.

I am part of the global management team, responsible for everything that has to do with supply chain management. The directors of our D&SCs report directly to me.

You are currently using AIMMS to enable your S&OP process. What was the driver to look for S&OP technology and how did you do things before?

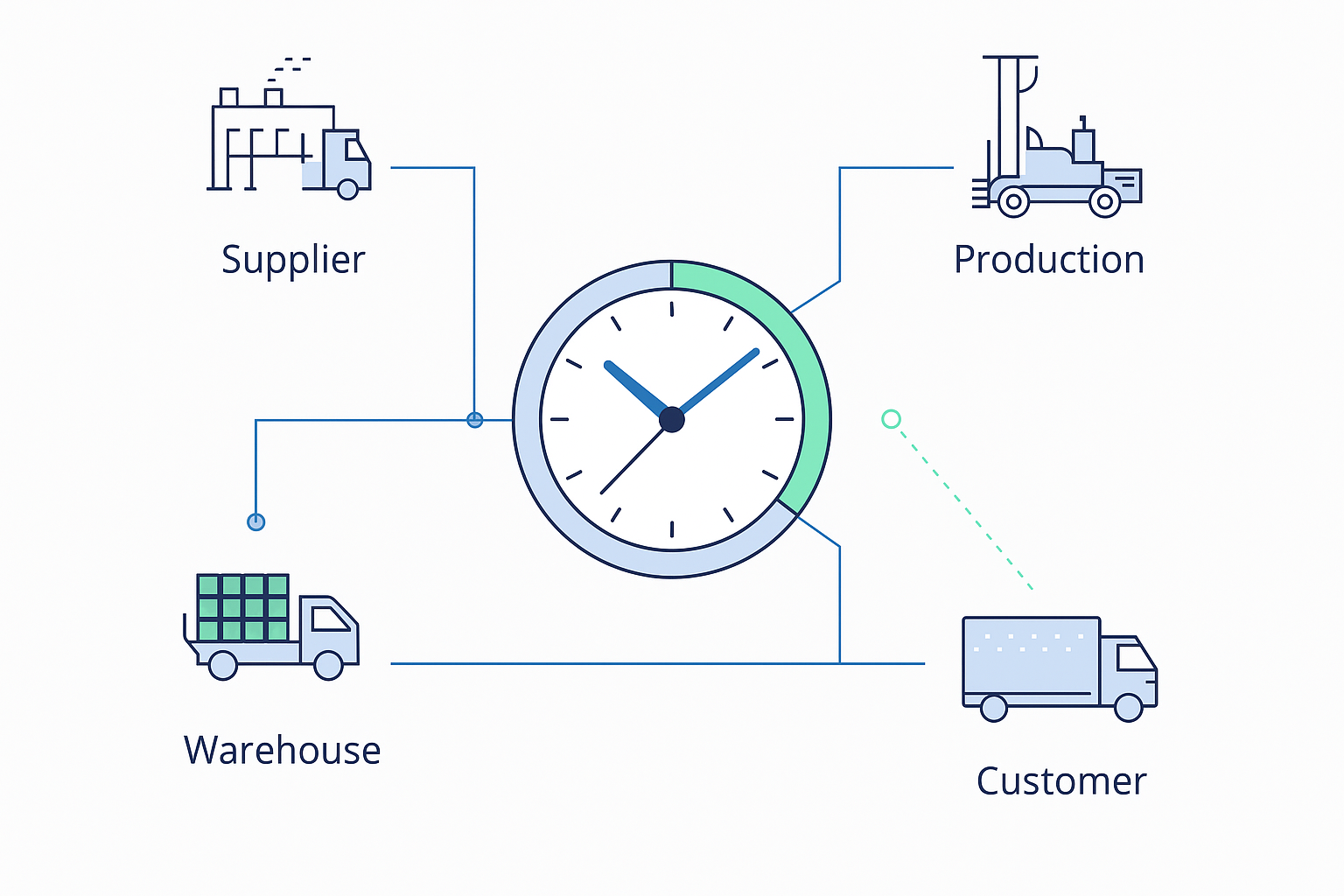

We have worldwide demand for all kinds of products and services and as I mentioned before, we have 3 different factories. We were trying to optimize the workload between these factories to have our manufacturing be as efficient as possible.

We had a financial reporting tool and based on the financial forecasting of our different sales subsidiaries, we made a forecast for products and services which was translated into a monthly demand plan and a capacity plan. This process was based on a lot of assumptions.

There was one particular guy within the company who was very experienced. He had been working with us for more than 20 years. He gathered and looked at the data and would produce a forecast based on previous experiences. He was changing forecasting data upon verification but also based on gut feel. This posed a lot of risk for our company.

That’s why I decided that this should change completely and decided to embrace S&OP.

And you were using spreadsheets?

Yes, everything at Boon Edam was done in spreadsheets. We still use them for many purposes – which is something I would like to see less.

Could you indicate why it was the right moment to switch to an AIMMS-based S&OP support system?

We were transitioning to work with different business models. Manufacturing to Order is our primary process. Sometimes we get Engineering to Order requests, so we have to engineer products based on customer requirements. Now, we see increasingly more Assembly to Order requests for security products. So we were looking to shift towards a combined business model of Made to Stock and Assembly to Order – where modules which could be placed into a configuration requested by the customer would be ready for production. This meant we needed a different logistics approach to fulfill these orders.

So you decided to shift towards S&OP, what did this journey look like?

The most difficult part of this journey was to convince my fellow colleagues and the board of directors. Besides AIMMS, we had started implemented SAP. This is a huge project within Boon Edam worldwide that requires a lot of our workforce and resources. Within SAP, there is also a solution called S&OP. So I had to justify why we needed AIMMS instead of using this SAP solution.

I provided my colleagues with different business cases. I explained that AIMMS can be built according to our requirements. Rather than a standard solution from SAP, which could be tweaked according to our requirements but never to the same extent AIMMS could be. Moreover, building different scenarios – one of my pre-requisites for AIMMS – was not really possible within SAP. Doing that meant manipulating data within SAP, and that’s not advisable as I’ve learned from experience.

In short, the biggest struggle was to convince my fellow workers to invest in the AIMMS platform and sign off on the hours we needed from ORTEC (an AIMMS implementation partner) to build it according to our specifications.

How did you convince them?

The ability to build different scenarios and the fact that we didn’t have to compromise and start using a complicated tool like SAP’s helped. With AIMMS, we could also learn during the development of the tool. We took ownership of it. We involved people from the different sales subsidiaries. We involved people from manufacturing and supply chain. The configuration of the tool was partly designed by them. That’s a big advantage from a change management and stakeholder management perspective.

I learned that the whole process is not just about the tool, it’s also about getting people committed to using the tool and working according to the processes which are needed to make S&OP successful. It’s about the whole circus of getting people involved, committed and building something together to get the benefits of it. It’s much more than a tool.

In the beginning everybody thought “this is extra work.” “Why are we doing this?” “We already do financial forecasting, so why do we need another tool, another process…”

Change management is the toughest part. The development of the AIMMS App is the nice part. Now, we have 25 different Boon Edam companies involved, with 10 people aligned in different regions of the world using the tool.

What does your planning horizon look like? Can you explain your S&OP process at Boon Edam?

We do it monthly in 3 different regions. Every month, supply chain managers from our different D&SCs submit a template completed for uploading into the AIMMS application. They are supported by my assistant, who is the Global SC Coordinator. They have their regional session with manufacturing mainly to discuss the demand plan, compare it with the inventory at the different D&SCs and with capacity levels at the factories.

We’re making it work regionally first. The next stage is to do it on a global basis so supply chain managers can check whether goods can be shipped from another D&SC according to stock levels, for instance. Part of this process requires challenging yourself. Within the D&SCs, we have account managers who call their counterparts within sales subsidiaries to check forecasting and demand.

We’re now aiming to get higher forecast accuracy. Our accuracy now is 50% and we are aiming to get 30% more before the end of this year. Our forecast horizon, which is also part of S&OP, is currently 4 months and we’re aiming for 6 months before the end of 2017.

Sometimes we get very accurate forecasts with a limited amount of data and sometimes we get a lot of numbers but the forecast is very poor. I am shooting for something in the middle. Right now we are missing a lot of data, so we have some work to do still.

Is this integrated into your ERP, SAP?

Not yet, but that’s what we’re aiming for. Then we’ll have a more consistent way of getting our data.

So you do S&OP on a monthly basis and you have your monthly meeting. During the meeting, do you change the data to see different capacity constraints?

Yes, my team does this during the Pre-S&OP meeting. There are 5 steps: data gathering, demand plan, supply chain, pre-S&OP meeting with local directors, and then a meeting with SC people and manufacturing people. When there is a constraint which needs to be escalated, it comes to me and then I discuss it with my colleagues in our global MT meeting. These meetings tend to go very smoothly now because we can study the data to make better decisions.

Can you tell me more about how Boon Edam’s management team uses the output? Do they enjoy using the tool?

Yes, the graphics are good. You can see demand, capacity and inventory in a single view. We’re now building up our data to start seeing the benefits in cost savings and efficiency improvements.

We often hear people say that they need to focus on their data first. You obviously took another stance on that. Could you tell me why?

Like I mentioned, I think it’s very dangerous to put together a demand forecast that’s not based on real data but based on all kinds of assumptions. I’d rather have a poor forecast based on data than something based on gut feeling. Having the benefit of foresight based on data is powerful.

Let’s say we are expecting a big spike in demand in August-September, but in July because of the holidays, demand is very limited. Based on this demand spike, I can ask people to work in August-September. This decision is not based on assumptions but based on the data provided by our sales people, which is something much better.

I wanted to stop making decisions based on gut feeling, and take decisions based on real data.

Do you feel AIMMS has contributed to your business model transition?

Yes, we get much better insight into the data provided by the different sales subsidiaries. Now, we can really work on improving forecast accuracy and forecast horizon.

We have a much more objective way of interpreting the demand data given by the sales subs. This opens up discussions and gives us much more clarity about our processes – which can be translated into efficiency.

You mentioned that you use different what-if scenarios within AIMMS. Do you use AIMMS for optimization as well?

Yeah, we do. For instance, use statistical forecasting in AIMMS to determine how much demand we should approve based on calculations done within the tool.

What’s on your wish list?

What I want is to enter the office and see a dashboard with different KPIs in a single view: inventory return, forecast accuracy, how many shipments we have. Supply chain KPIs, but also financial KPIs. A single dashboard where I can manage my supply chain, tweaking the different KPIs to improve efficiency and service level to our customers. This takes time, but we’ll get there.

Looking to jumpstart your S&OP process with an agile technology? Learn about AIMMS S&OP, a Sales & Operations Planning Application that is quick to configure and intuitive to use. It facilitates ease of collaboration and uses powerful, embedded Prescriptive Analytics for scenario modeling. S&OP Navigator is part of SC Navigator, a suite of configurable Apps helps you uncover hidden opportunities, answer unresolved questions and fast-track mission critical decisions.